No.1 in Smart Factory Training Equipment, Fostering Field-Ready Technicians

World’s First DX Labeler: Leading Process Innovation

Spreading the Korean Technology Education Model Through ODA Initiatives

"We will build an advanced technology education platform to create a global education hub that attracts talent from around the world." On August 11, at the IG headquarters in Seongnam, Gyeonggi Province, CEO Kim Changil of IG announced his plan to establish 'K-Tech-Edu' as a global standard through a platform set to launch in January next year. Tech-Edu refers to a business model in which technology companies take the lead in education businesses. He presented a vision of becoming a global top-tier company based on this model and the education platform. Kim's vision resonated with Kolon Investment and IBK Venture Investment, resulting in a total investment of 5 billion KRW in December last year.

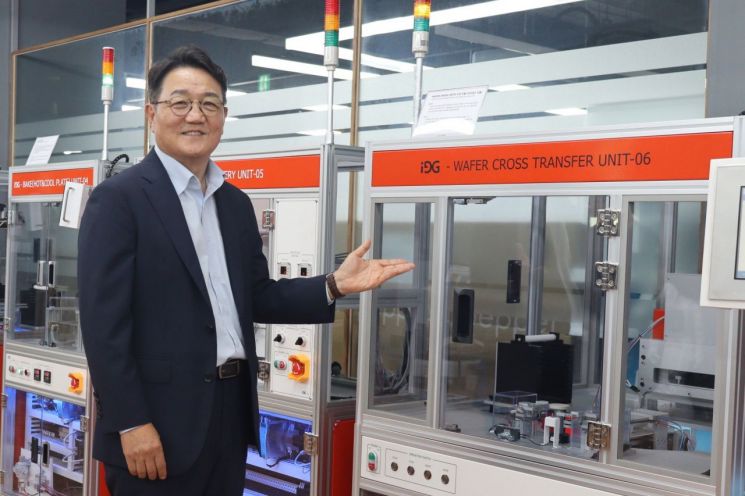

Kim Changil, CEO of IG, is introducing semiconductor process training equipment at the IG headquarters in Seongnam, Gyeonggi Province on the 11th. InnoBiz Association

Kim Changil, CEO of IG, is introducing semiconductor process training equipment at the IG headquarters in Seongnam, Gyeonggi Province on the 11th. InnoBiz Association

No.1 in Smart Factory Training Equipment, Fostering Field-Ready Technicians

The Tech-Edu company IG was established in 2009. It has developed advanced technology manufacturing process training equipment and systems tailored for smart factory environments, covering fields such as semiconductors, smart factories, robotics, and automatic control. Last year, the company recorded sales of 23.7 billion KRW and currently holds the No.1 market share in Korea's smart factory-based vocational training equipment market. One of its strengths is a solid technological foundation, with 65% of its 62 employees being technical personnel.

IG has independently developed a hands-on training system that integrates augmented reality (AR), virtual reality (VR), digital twin-based educational content, and a manufacturing execution system (MES), providing solutions that connect education and industrial sites. The customized training equipment supplied to universities, technical education centers, and public training institutes is a modular automation process system that replicates real industrial environments, allowing students to learn design, control, and data analysis. Through this, educational institutions can provide vocational training at the level of actual workplaces, enabling them to nurture the talent that companies need.

IG employees are demonstrating virtual reality (VR)-based smart factory training content. Photo by Ho-Kyung Choi

IG employees are demonstrating virtual reality (VR)-based smart factory training content. Photo by Ho-Kyung Choi

The demonstration on this day showcased IG's technological capabilities firsthand. Employees conducted vocational training using smart factory training content powered by VR and digital twin technology, which was synchronized in real time with actual training equipment. Vice President Gong Younggeol explained, "IG aims to foster 'technicians' who understand the entire process, not just engineers," adding, "This is also the core concept of smart factory education."

World's First 'DX Labeler'... Achieving Both Quality and Efficiency

IG is also achieving results in its other main business, industrial solutions. In particular, the DX Labeler is the world's first 'high-speed automatic labeling system for smart factories,' completed by integrating automation, control technologies, and field expertise honed through its education business. It automatically prints and attaches labels to products in real time by linking with production planning systems such as MES. The system is optimized for high-mix low-volume production, high-speed production lines, and automated packaging lines. According to IG, this enables both efficiency and flexibility in advanced smart factory processes. Vice President Kim Seongtae stated, "The domestic patent has already been registered, and we are currently applying for an international patent."

The DX Labeler is currently being supplied to major manufacturing sites both in Korea and overseas, including LG Electronics' Poland plant (high-speed home appliance production line) and Osstem's Daegu plant (smart automated packaging line), contributing to improved quality control and production efficiency. IG has also begun developing a lightweight model for small and medium-sized enterprises (SMEs). There had been feedback that the initial adoption cost of the existing product was burdensome for SMEs. Vice President Kim said, "We are preparing a version with a lower price and reduced installation burden, aiming for release at the end of this year or early next year."

Accelerating Global Expansion Toward Top-Tier Status

IG is also working to spread the Korean-style technology education model overseas through Official Development Assistance (ODA) projects and KOICA-linked development cooperation initiatives. Since 2022, the company has supplied smart factory-based advanced technology training equipment to Kenya-AIST (Kenya Advanced Institute of Science and Technology), supporting technology transfer. Building on this, IG plans to accelerate its entry into global markets.

Vice President Kim stated, "Only a few countries, such as Germany, Italy, and France, manufacture educational equipment for training purposes themselves; all other countries rely entirely on imports." He added that there is particularly strong interest in Korea's technology education in developing countries, which have achieved industrialization in a short period of time. IG aims to seize this opportunity to become a global top-tier company, competing with European powerhouses that have over a century of history.

CEO Kim Changil said, "To realize the practical implementation of smart factories, we are continuously pursuing innovative solutions that encompass both technology development and talent cultivation." He added, "Going forward, as a 'partner in global manufacturing innovation,' we will lead technology innovation centered on education and contribute to the digital transformation of manufacturing sites through customized DX projects."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)