The global trend toward automation for quality innovation in manufacturing is accelerating. In particular, in high-precision industries such as automotive parts, semiconductors, and steel sheets, precision inspection automation that can detect even microscopic defects invisible to the naked eye has become a key factor determining corporate competitiveness.

In response to these market demands, TNSAi Co., Ltd., which has developed and commercialized 3D non-standard product inspection equipment based on On-Device Artificial Intelligence (On-Device AI), is attracting attention. On-Device AI refers to artificial intelligence that collects and learns data independently on individual devices, without the need for servers or information and communication networks.

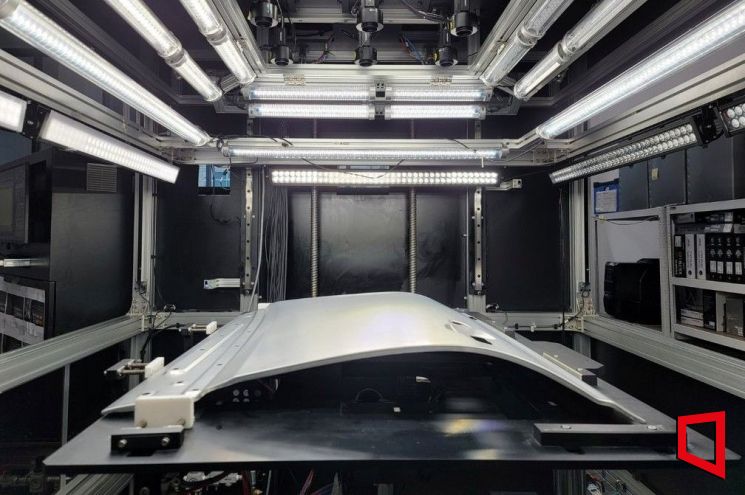

The company is setting a new standard for quality inspection in manufacturing by integrating AI, vision systems, and robotics technology.

Overcoming the Limits of Quality Inspection with 'On-Device AI' Technology

TNSAi has implemented 'On-Device AI' technology, embedding AI computational capabilities directly within its equipment to enable ultra-fast and high-precision inspection without the need for servers or external networks. In particular, the company provides ultra-precision automated inspection solutions capable of accurately detecting defects such as ultra-fine bumps, dents, and scratches on 3D non-standard shaped products, which are impossible to identify with the naked eye.

Starting with the automotive parts industry, the company is rapidly expanding its business scope to include real-time large-area surface inspection of plastic extrusion and injection products, cold-rolled steel sheets, and other industries that require inspection of highly reflective products.

Strengthening R&D with VC Investment and Securing Major References

TNSAi began attracting investment from Shinhan Venture Investment in April last year and is currently in the process of securing bridge investment. Leveraging this, the company has significantly strengthened its research and development capabilities and has completed PoC (Proof of Concept) with major domestic automotive parts manufacturers. Large-scale supply contracts are scheduled to be signed starting this year.

In particular, TNSAi's ultra-high-difficulty real-time large-area 3D non-standard defect detection technology was applied to large press-processed panels at a first-tier supplier of Hyundai Motor Company, successfully verifying its potential. In addition, the company has signed supply contracts for AI inspection equipment dedicated to large-area cold-rolled steel sheets used in refrigerators, washing machines, and air conditioners, and is preparing for delivery.

Securing Competitive Advantage with Differentiated Converged Inspection Solutions

TNSAi's competitiveness lies in its clearly differentiated converged technology compared to existing competitors. The company manufactures and supplies 'All-in-One' inspection equipment that integrates its proprietary AI deep learning software and reusable automotive foundation models, optical vision system technology, and robot-linked automation technology.

This is the biggest differentiator from competitors, which are mainly limited to component-based or SI business models, and it enhances customer convenience from a maintenance perspective in the future.

Additionally, TNSAi has overcome issues of gloss and reflection on 3D products by using the Motion Swing Handler Robot, which solves the problem of light diffusion, and an Auto-Focusing algorithm, enabling real-time accurate defect detection even on three-dimensional products.

Full-scale Entry into the Global Market

In 2022, TNSAi became the first in the world to mass-produce brake disc inspection equipment capable of 100% inspection and has been continuously supplying it to the brake disc production lines of Hyundai and Kia Motors.

Now, having gained recognition for its technology, the company is accelerating its efforts to enter the global market beyond Korea. Currently, through a global trading company that supplies manufacturing equipment to Japan, TNSAi is carrying out projects to supply brake disc inspection equipment to Honda and Nissan, and is also planning to enter the North American and European markets in the future.

Future-oriented Inspection Technology Leading Manufacturing Innovation

TNSAi's inspection solution, which integrates 'AI + vision system + robotic automation' into one, is expected to become a key infrastructure for manufacturing innovation in areas such as smart factories, electric vehicle parts, semiconductor manufacturing, and metal and plastic processing.

TNSAi plans to expand its business beyond automotive parts, semiconductors, and steel to include the aerospace, defense, and high-precision parts industries. In particular, by advancing On-Device AI computation and edge computing-based technology for ultra-precision surface inspection of 3D non-standard large-area products, the company will accelerate the global expansion of its automated inspection equipment.

"Innovating Industry and Benefiting the World through Technology"

TNSAi CEO Tae Seokho has consistently maintained his management and technology development philosophy of "innovating industry and benefiting the world through technology."

He emphasizes, "The technology we create is not just a product, but a new standard that transforms industrial sites. Through continuous innovation and the creation of customer value, we will prove the competitiveness of Korea's manufacturing industry in the global market."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)