Hankyung Association 'New Industry Proposal' Series

2028 Production Capacity to Grow 5.3 Times from 2022

"Easing Product Certification Standards, Including New Growth and Core Technologies"

As the global production capacity of biodegradable plastics is expected to grow at an average annual rate of 32.2% until 2028, the business community has suggested the need for policy support such as easing certification standards. They advocated for relaxing product certification criteria and including composting technology as a new growth and core technology to increase tax credit rates. They also proposed adjusting the contents of the 'large enterprise-small and medium enterprise (SME) win-win agreement' to allow large-scale facilities that sort plastic waste into general plastics and biodegradable plastics to be deployed on-site.

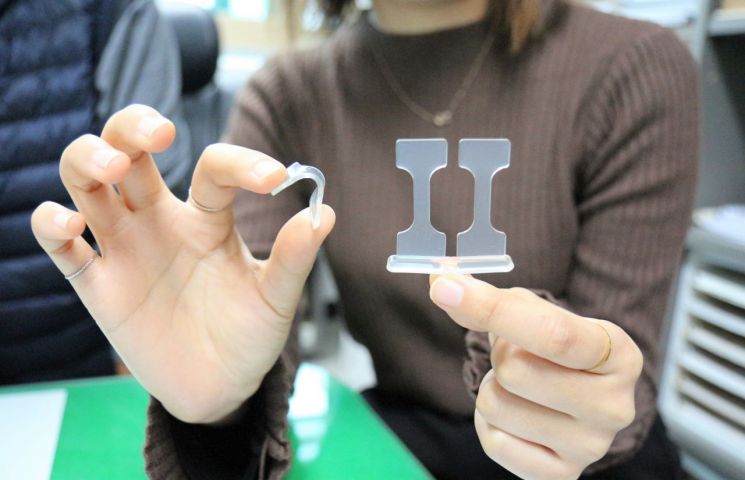

Biodegradable plasticizer lactide oligomer capable of producing 100% biodegradable bioplastics.

Biodegradable plasticizer lactide oligomer capable of producing 100% biodegradable bioplastics. [Photo by Korea Research Institute of Chemical Technology]

On the 13th, the Korea Economic Association announced biodegradable plastics as the second installment of its 'New Industry Proposal Series,' summarizing related industry trends and challenges. Biodegradable plastics are plastics that decompose within a short period under natural or decomposition facility-required environments. They enable eco-friendly decomposition and have physical properties similar to conventional plastics, making them suitable for use in packaging materials, agricultural films, and other products.

According to the European Bioplastics Association, the global production capacity of biodegradable plastics is expected to reach 4.605 million tons by 2028, a 5.3-fold increase compared to 864,000 tons in 2022. The estimated average annual growth rate is 32.2%. In Korea, companies such as SK Livio, LG Chem (petrochemical company), and CJ CheilJedang (bio company) are developing and producing biodegradable resins. SK Livio has started construction of a 70,000-ton-per-year petrochemical raw material biodegradable plastic (PBAT) plant in Haiphong, Vietnam. LG Chem established a 50,000-ton-per-year PBAT plant in Seosan, Chungnam, and began mass production this year.

Major countries are trying to reduce plastic pollution by utilizing biodegradable plastics. The United Nations Environment Programme (UNEP), under the United Nations (UN), established the Intergovernmental Negotiating Committee (INC) for Plastic Pollution Reduction in March 2022. INC plans to enact internationally binding plastic pollution reduction regulations after its 5th meeting in Busan this December. Notably, at the 2nd meeting in June last year, it was suggested that biodegradable plastics could be considered as alternatives if reasonable standards are established.

The United States, China, Japan, and others have introduced or plan to implement policies for the commercialization of biodegradable plastics. Since 2002, the U.S. federal government has mandated preferential purchasing of USDA-certified biobased products (currently 139 items). Some states have introduced legislation encouraging the use of single-use packaging made from biodegradable materials.

China plans to gradually restrict the production and use of single-use plastics by next year and aims to promote biodegradable plastics as alternative products at the national level. Japan plans to introduce 2 million tons of bioplastics by 2030. It has enacted related laws to provide a basis for the private sector to autonomously collect and recycle plastic waste.

The Korea Economic Association stated that Korea should also ease certification standards for related products to revitalize the biodegradable plastics industry. Currently, the standards that must be met to be certified as products using biodegradable plastics are 'industrial composting' and 'soil biodegradation.' Industrial composting certification will be uniformly terminated from next year. In contrast, countries such as the U.S., China, and Japan recognize industrial composting as a standard.

Korea views industrial composting-certified products as having limitations in biodegradation when simply landfilled. Major countries consider that industrial composting-certified products can sufficiently biodegrade if processed in soil (composting facilities) at high temperatures of 50-60 degrees Celsius with adequate oxygen supply. A Korea Economic Association official said, "If Korea eases certification standards to maintain industrial composting certification, it will be able to compete under the same conditions as major countries."

The Korea Economic Association proposed including biodegradable plastic composting technology as a new growth and core technology. For large enterprises, the R&D investment tax credit rate for new growth and core technologies is 20-30%, and the facility investment credit rate is 3%.

They also suggested adjusting the win-win agreement between large and small-medium enterprises to improve infrastructure for sorting plastic waste into biodegradable and general plastics. Since the 'Plastic Recycling Industry Large-Small Enterprise Win-Win Agreement' was signed in November 2022, large enterprises have been prohibited from newly entering or expanding the sorting of household plastic waste, which is mainly generated at homes.

Lee Sang-ho, head of the Economic and Industrial Headquarters at the Korea Economic Association, said, "Major countries are focusing on biodegradable plastics as an alternative to regulations on the production and use of non-degradable plastic waste," adding, "Korea should also create a favorable policy environment to practically establish the biodegradable plastics market."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)