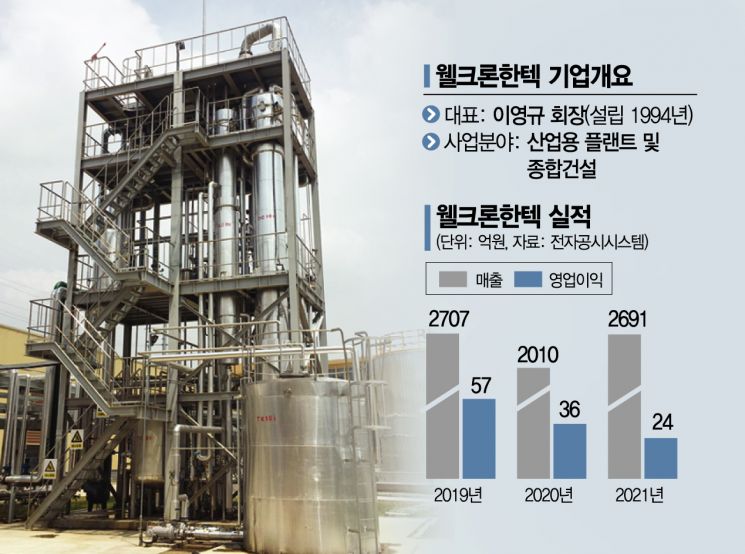

Industrial Plant and General Construction Company Welcron Hantec

Recovers Pure MC Only from Waste Solution Using Solvent Recovery Equipment

Costly Secondary Battery Separator Membranes... 99% Recycling Reduces Production Costs

European Union (EU) Aims to Enforce 'Sustainable Battery Act' Within the Year

Major Domestic and International Separator Manufacturers Rush to Adopt for Cost Reduction

[Asia Economy Reporter Kwak Minjae] Welcron Hantec’s concentration equipment, previously used in the food and beverage and bio industries, is gaining new attention in the electric vehicle battery market as it is now being applied to the secondary battery materials sector. Although the technology itself was developed over a decade ago, applying it enables stable raw material supply and cost reduction in battery manufacturing through the recycling of core materials. With intensified competition for securing secondary battery raw materials due to the COVID-19 pandemic, the Ukraine war, and the expansion of the electric vehicle market, demand for this equipment is growing even further.

Welcron Hantec, an industrial plant and comprehensive construction company, entered the secondary battery market in 2016 by supplying lithium hydroxide concentration and crystallization equipment. Welcron Hantec’s concentration equipment is used to increase the concentration of raw material solutions or to separate and crystallize specific components in aqueous solutions with high purity. The solvent recovery equipment, which applies this technology, distills and purifies pure MC (methylene chloride) and oil from waste MC mixed solutions generated during the wet membrane manufacturing process.

According to Welcron Hantec, major domestic and international membrane manufacturers are rushing to adopt solvent recovery equipment to reduce costs. Representative global membrane manufacturers with large-scale production capacities include China’s Shanghai Energy (SEMCORP) and Jinli New Energy Co., Ltd. (GELLEC). Shanghai Energy is a subsidiary of Changxin New Materials, the world’s largest EV (electric vehicle) battery separator supplier. Most of these companies reportedly recycle hundreds of tons of MC daily through Welcron Hantec’s solvent recovery equipment, achieving cost savings.

There are several reasons why Welcron Hantec’s solvent recovery equipment is gaining attention in the electric vehicle market. First, this technology can reduce the production cost of secondary battery separators. Separators are the second highest cost component in secondary batteries after cathode materials. Among them, MC is an organic solvent used to remove oil from separator films and is an essential, expensive material for wet separator production. In the past, simply reusing waste MC negatively affected separator yield, so most of it was discarded after use.

In contrast, by utilizing solvent recovery equipment, MC can be recovered with high purity from waste solutions mixed with oil, enabling over 99% recycling. According to Welcron Hantec, their solvent recovery equipment has the advantage of reducing the required site area to less than half compared to other companies’ equipment while handling a high daily processing volume.

The fact that environmental regulations on batteries are becoming more stringent is also positive. The European Union (EU) has announced plans to regulate the proportion of recycled raw materials in batteries starting in 2030. The 'Sustainable Battery Act,' which includes mandatory recycling of battery raw materials, is also expected to come into effect within the year. This emphasizes the need for resource circulation throughout the entire battery value chain.

Welcron Hantec also possesses waste battery recycling equipment that refines and recycles cathode materials, which determine the price of secondary batteries. The company explains that as the electric vehicle market grows, the importance of technologies that efficiently refine and recycle rare and valuable metals such as lithium and nickel increases from the perspective of battery cost reduction.

A Welcron Hantec official stated, "Our concentration and crystallization equipment can reduce energy consumption by up to 94% based on energy-saving technology that reuses steam and a high-efficiency continuous design, leading to increased inquiries about waste battery recycling equipment from related companies." He added, "We plan to actively target the global secondary battery materials market based on our concentration and crystallization technology, including separator solvent recovery equipment and waste battery recycling equipment."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)