Shim Kwang-woo, CEO of Sinhwa Engineering

"Let's Make Electric Vehicle Parts" Decision

Increased Sales by Introducing Smart Factory

New Supply of Electric Tool Parts

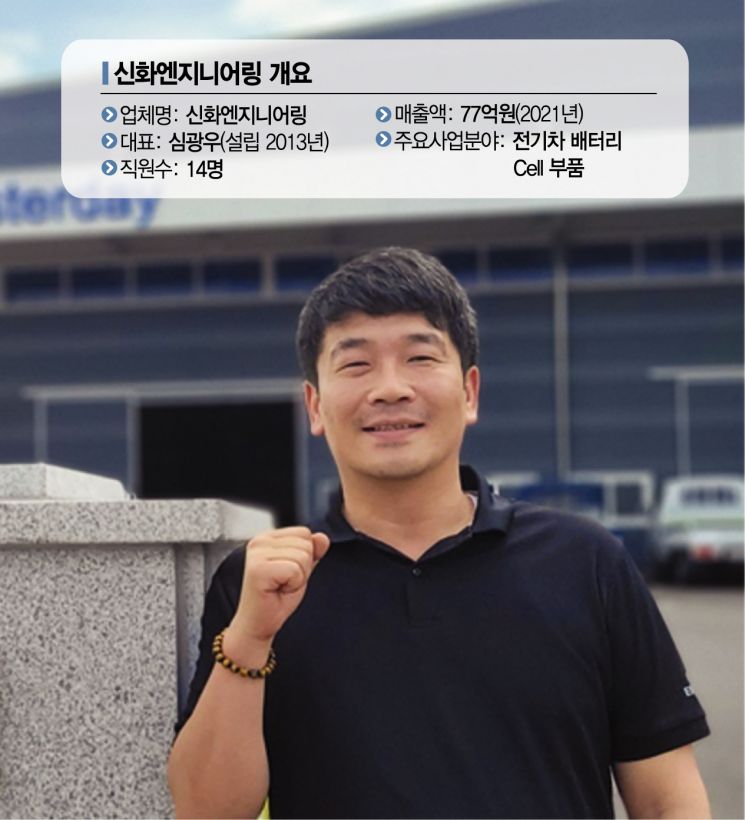

"The industrial transition to electric and eco-friendly vehicles will pose a crisis for existing internal combustion engine parts manufacturers. We must find a way to overcome this." Since its founding in 2013, Shinhwa Engineering, which mainly produced internal combustion engine parts as a third-party vendor for Hyundai and Kia Motors, faced deep concerns. This was due to the rapid shift in the industrial ecosystem from internal combustion engines to eco-friendly electric vehicles. However, CEO Shim Kwang-woo of Shinhwa Engineering (pictured) believed that the crisis could instead become an opportunity. To develop new products suited to the rapidly changing environment and improve production efficiency, they decided to introduce a smart factory. Shim’s decision proved correct. Despite the difficulties faced by automotive parts companies due to the global semiconductor shortage and the resulting sharp decline in vehicle production volumes, Shinhwa Engineering transformed into an eco-friendly automotive parts company, laying the foundation for sustainable growth.

On the 7th, CEO Shim said, "The efficient production process of the smart factory continues to this day." Shinhwa Engineering produces ‘insert nuts’ used in electric vehicle battery cells. Insert nuts are key components of electric vehicles that transmit current from the battery to the motor and serve to align and fix the battery cartridge. Since last year, the company has diversified its sales channels by supplying parts for power tools to DeWalt in addition to automotive parts manufacturing.

Shinhwa Engineering’s previous main products were engine bearing parts and parking brake cable parts. Although structural innovation was necessary, it was not easy for a small and medium-sized enterprise to actively enter the electric vehicle parts market. Moreover, the COVID-19 pandemic and supply chain disruptions posed significant challenges to local manufacturing SMEs.

CEO Shim trusted the company’s capabilities built through continuous research and development (R&D) since its founding. Shinhwa Engineering invested early by participating in parts development from the initial stages of the domestic electric vehicle industry, ahead of other companies. Core automotive parts require strict quality control and precision machining with no tolerance for even minor errors. For electric vehicle parts, suppliers must meet technical and quality conditions such as pre-machining to prevent vehicle fires, surface roughness, and plating to qualify for supply. Shim explained, "We have never neglected technology development and continue strict management to provide customers with the highest quality through process efficiency."

In this process, support from the Small and Medium Business Corporation (SBC) played a decisive role. Receiving funding for smart manufacturing in 2020 enabled the establishment of a smart factory with an automated line capable of low defect rates and rational process adjustments. The production process, precisely operated by three robots, became a major asset for Shinhwa Engineering. They also commercialized more than three technologies with support for technology development and commercialization funds. Results are materializing: sales increased from about 5.2 billion KRW in 2020 to 7.7 billion KRW last year, and this year sales are expected to exceed 10 billion KRW.

CEO Shim emphasized, "Until now, it was a period of laying the foundation as a startup. Going forward, we will achieve diversification of product lines and continuous technological development of our current core eco-friendly automotive parts," adding, "We will establish ourselves as a company that contributes to regional economic development."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)