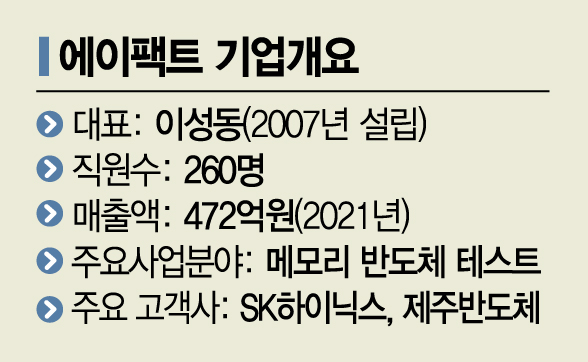

Memory Semiconductor Test Company A-FACT... SK Hynix Largest Client

MOU Signed for Package Sales Transfer to Acquire AT Semicon

Plan to Establish Integrated Package and Test Post-Process System at Eumseong Plant 2

Introducing Semiconductor Test Equipment for Automotive Electronics

"Aim for 30% Non-Memory Share and 300 Billion KRW Sales within 5 Years"

[Asia Economy Reporter Kwak Min-jae] Semiconductor processes are broadly divided into front-end processes, which manufacture wafers (substrates) according to design specifications, and back-end processes, which package and test the completed wafers to create the final chips. Recently, as front-end process technology has reached its limits in improving performance in ultra-fine semiconductor processes, the importance of back-end processes has grown even more. A-FACT is a company that tests packaged semiconductors during the back-end process. SK Hynix is its largest client.

Lee Sung-dong, CEO of A-FACT, said, "Compared to 10 years ago, semiconductor integration density has increased more than 200 times, which has extended semiconductor testing times and raised technical barriers to verifying cells. A-FACT has handled 70-80% of SK Hynix's memory semiconductor testing for 15 years and has been ranked first in SK Hynix's tester evaluations for four consecutive years, receiving excellent evaluations in quality, productivity, and technology."

◆ Acquisition of AT Semicon to Diversify Packaging Business = A-FACT's main business is testing, which inspects the electrical functions of semiconductor devices to determine product defects and analyzes the causes of defects to improve yield in design and manufacturing processes. It mainly tests memory semiconductors such as DRAM and NAND flash. Last year's sales amounted to 47.2 billion KRW.

Among domestic memory testing companies, it is the only one possessing hybrid burn-in technology. With a single testing device, it can simultaneously perform testing and burn-in processes that detect early defects through stress testing at 125 degrees Celsius. CEO Lee said, "High-spec non-memory semiconductors used in vehicles and satellites require initial reliability, so the importance of hybrid burn-in technology will also be recognized in the non-memory market."

A-FACT was established in 2007 as a joint investment by SK Hynix partner companies outsourcing semiconductor testing. It changed its name from HiSem to A-FACT two years ago. CEO Lee is a back-end semiconductor expert who joined SK Hynix as a test engineer, gained experience in packaging, and served as head of SK Hynix's Chongqing branch and as an executive. He joined this company in 2019 and was appointed CEO.

To expand its business into the packaging sector, A-FACT is in the process of acquiring AT Semicon, a semiconductor back-end company. On the 12th of last month, they signed a memorandum of understanding (MOU) for the transfer of packaging sales. The main contract is expected to be finalized by August this year at the latest. Packaging is a core back-end semiconductor process that packages semiconductor chips so that the wafer with circuits engraved and electronic devices can communicate signals. AT Semicon counts both SK Hynix and Samsung Electronics as clients, and the company explains that if A-FACT acquires it, sales diversification is expected.

◆ Establishing an Integrated Back-End Process System... Targeting 300 Billion KRW in Sales = A-FACT has made large-scale facility investments to enter the long-awaited packaging business. In 2020, it completed the Chungbuk Eumseong plant with a total investment of 52 billion KRW. The Eumseong plant, with a total floor area of 115,000 square meters, is the second plant following the headquarters in Anseong. After acquiring AT Semicon, A-FACT plans to invest 12 to 13 billion KRW next year to establish a packaging line at the Eumseong plant and an additional 20 billion KRW by the end of next year to introduce non-memory testing equipment. This will enable the Eumseong plant to establish an integrated back-end process system from packaging to testing.

CEO Lee said, "If we establish an integrated process system where packaging is completed on the first floor of the Eumseong plant and testing is done on the second floor, we can reduce costs related to logistics transfer and minimize the possibility of wafer damage, thereby enhancing stability. Most importantly, if a claim arises from a client, the turnkey back-end service allows for rapid cause identification and feedback, which is encouraging."

A-FACT is also accelerating its push into the non-memory market. It has deployed dedicated sales personnel and engineers at its Pangyo sales office to actively pursue orders in the non-memory sector. CEO Lee stated, "Our goal is to achieve 30% non-memory share and 300 billion KRW in sales within five years through client diversification. We aim to grow into a global semiconductor back-end company capable of both memory and non-memory packaging and testing."

Anseong, Gyeonggi Province = Reporter Kwak Min-jae

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)