[Asia Economy Reporter Junho Hwang] Domestic researchers have developed the world's first digital X-ray source. This marks the evolution of the X-ray source into its second generation after more than 120 years. The digital X-ray source has the advantage of reducing radiation exposure by more than half while enabling precise and rapid imaging. In particular, by not using Japanese-made components, it has also achieved the localization of parts and secured global leadership.

The Electronics and Telecommunications Research Institute (ETRI) announced on the 15th that it has successfully commercialized the world's first carbon nanotube (CNT)-based digital X-ray source. This signifies the evolution of the X-ray source into its second generation. Currently, the X-ray source devices used in the medical field are analog X-ray sources modeled after the device Wilhelm Conrad R?ntgen used to discover X-rays 120 years ago.

120-Year History of X-ray Source Innovated Digitally

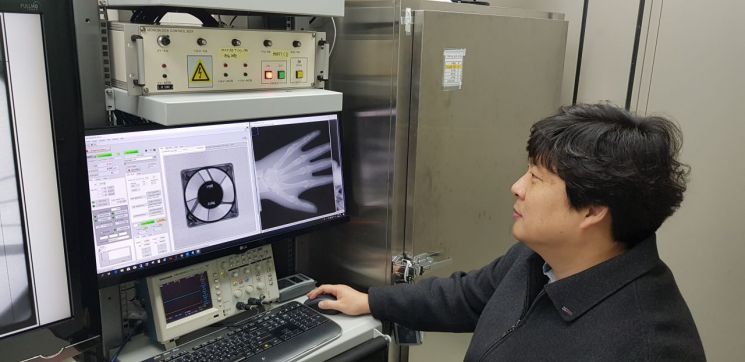

Jinwoo Jeong, a senior researcher at ETRI, is inspecting the results captured with a digital X-ray source.

Jinwoo Jeong, a senior researcher at ETRI, is inspecting the results captured with a digital X-ray source.

The institute developed technologies including carbon nanotube field emission electron source fabrication, vacuum-sealed X-ray tube design and manufacturing, and active current control technology for driving the field emission digital X-ray source, successfully digitizing the X-ray source.

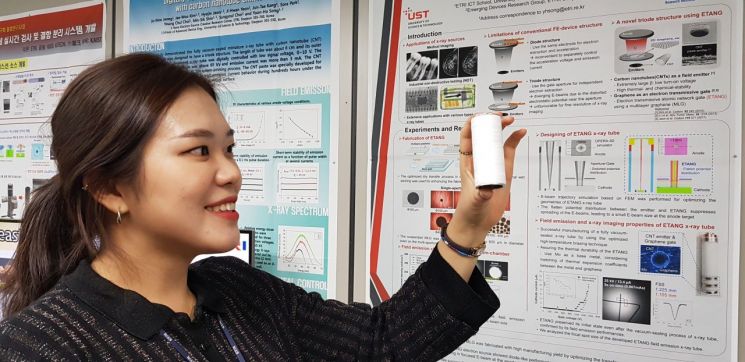

Notably, the research team identified the fundamental mechanism determining the lifespan of the carbon nanotube electron beam. Subsequently, through specialized high-temperature vacuum sealing technology, they developed the world's first commercial-grade X-ray tube. Despite efforts over the past 20 years in the US, Europe, and Japan to develop digital X-ray sources, none have succeeded.

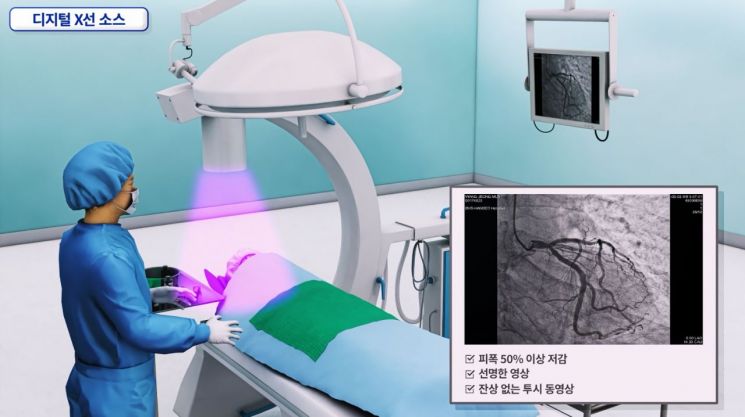

The digital X-ray source uses electrical signals instead of the conventional electron beam generation method. It was created by exploiting the phenomenon where electrons are emitted when a certain voltage is applied to an electron source made of carbon nanotubes. This device only applies electricity when needed to emit X-rays, reducing radiation exposure by up to 90% (average 50%) compared to existing devices.

Moreover, it can control current at the level of several hundred nanoseconds (ns), enabling imaging at speeds more than 10,000 times faster than conventional analog devices. The imaging speed can also be adjusted according to the movement of the object. For example, during vascular surgery, it can reduce the afterimage in X-ray imaging, allowing surgery with clearer images. The size can also be reduced to about that of an AA battery.

X-rays are electromagnetic waves used in medical diagnostics and industrial product inspections. X-ray sources mainly generate X-rays by colliding high-energy electron beams in a highly vacuumed space with metal. The operating method of the X-ray source is determined by how the electron beam is generated. Traditionally, filaments heated to 2000℃ have been used to emit electrons. However, this method poses risks of unnecessary radiation exposure and has limitations in improving image clarity and inspection time.

The institute has currently transferred the digital X-ray source technology to seven related companies, including two medium-sized enterprises.

A dental diagnostic equipment company that received the technology transfer stated, "We can now replace portable X-ray parts that were previously entirely imported from major Japanese companies." Another company reported, "We replaced the ionizer, a device that removes static electricity on industrial production lines, with a digital tube and received favorable reviews from display manufacturers."

Song Yunho, head of the Materials and Components Basic Research Division at ETRI, said, "By replacing core parts that had long been dependent on imports with innovative new technology, this has become a model case of securing global technological leadership beyond simple localization."

Professor Kim Jinseong of Yonsei University College of Medicine’s Department of Radiation Oncology and Medical Device Industry said, "ETRI’s technology enables precise control of X-rays, reducing concerns about radiation exposure while enhancing imaging characteristics, marking a technological turning point."

The institute plans to apply this technology to three-dimensional computed tomography (CT) systems in the future.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)