Catalysts are the "invisible engine" of hydrogen energy, as they play a crucial role in both hydrogen production and electricity generation. However, conventional catalysts, which use precious metals in particulate form, have been inefficient and have a short lifespan. To overcome these limitations, a new technology has been developed in Korea that reduces the use of precious metals while simultaneously enhancing the performance of hydrogen production and fuel cells. The key lies in "innovation in form" rather than in the catalytic material itself.

On January 21, KAIST announced that the research team led by Professor Cho Eunae of the Department of Materials Science and Engineering has developed a new catalyst structure that significantly reduces the use of precious metals while improving both hydrogen production and fuel cell performance.

The research focused on overcoming the efficiency and durability limitations of existing catalysts by utilizing an ultrathin nanosheet structure, which is only a fraction of the thickness of a human hair.

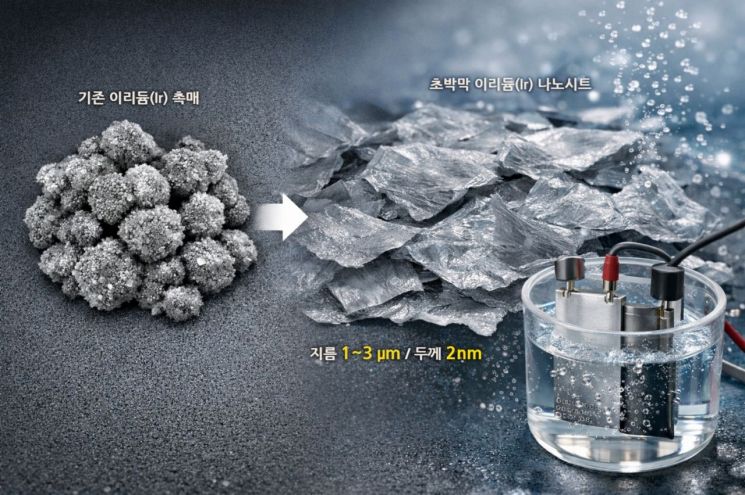

Image of the 'Ultrathin Iridium Nanosheet' developed by the research team (AI generated). Provided by KAIST

Image of the 'Ultrathin Iridium Nanosheet' developed by the research team (AI generated). Provided by KAIST

Water electrolysis devices and fuel cells are core technologies for the production and utilization of hydrogen energy. However, the iridium (Ir) and platinum (Pt) used as catalysts in these technologies are rare and expensive, which has been a major obstacle to commercialization.

More importantly, conventional catalysts are in the form of small particles, which limits the surface area available for actual reactions and makes it difficult to avoid performance degradation over prolonged use.

To address this, the research team devised an innovative approach by spreading the catalyst, which was previously clumped together like grains, into a thin and wide sheet-like structure. The team developed an ultrathin iridium nanosheet with a diameter of 1-3 micrometers and a thickness of less than 2 nanometers as a water electrolysis catalyst. This significantly increased the reactive surface area for the same amount of iridium, enabling more hydrogen to be produced from a smaller quantity of metal.

In addition, the ultrathin nanosheets were interconnected on a titanium dioxide (TiO₂) substrate, which was previously unsuitable as a catalyst support due to its poor electrical conductivity. This created a "pathway for electricity" and allowed titanium dioxide to serve as a stable catalyst support.

As a result, the catalyst structure developed by the research team achieved a 38% faster hydrogen production rate compared to commercial catalysts and demonstrated stable operation for over 1,000 hours under high-load conditions similar to those found in industrial settings.

Notably, even when the amount of iridium used was reduced by 65% compared to conventional catalysts, the new catalyst achieved the same performance as commercial products, proving that the use of precious metals can be dramatically reduced.

(From left) Hyunwoo Yang, PhD candidate at KAIST; Sangjae Lee, PhD; Eunae Cho, Professor; Dongwon Shin, PhD candidate. Provided by KAIST

(From left) Hyunwoo Yang, PhD candidate at KAIST; Sangjae Lee, PhD; Eunae Cho, Professor; Dongwon Shin, PhD candidate. Provided by KAIST

The research team also applied this ultrathin nanosheet design strategy to fuel cell catalysts, successfully creating a platinum-copper catalyst that is only a fraction of the thickness of a human hair and maximizing reaction efficiency. In fuel cell evaluations, this catalyst achieved a mass activity for platinum that was 13 times higher than commercial catalysts and delivered 2.3 times higher performance in actual fuel cell cells.

Furthermore, the catalyst retained 65% of its initial performance even after 50,000 accelerated durability tests, demonstrating superior durability compared to existing catalysts.

Professor Cho stated, "Through this research, we have proposed a new catalyst structure that dramatically reduces the use of expensive precious metals while simultaneously improving hydrogen production and fuel cell performance. This study will serve as an important turning point in lowering the cost of hydrogen energy and accelerating its commercialization."

This research was supported by the Energy Workforce Training Program of the Korea Institute of Energy Technology Evaluation and Planning under the Ministry of Trade, Industry and Energy, and by the Nano and Materials Technology Development Program of the National Research Foundation of Korea under the Ministry of Science and ICT.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)