From Electric Arc Furnaces to Chemical and Power Facilities

Electricity Rates Are Changing Factory Locations

"Energy Is Competitiveness"... Survival Strategies Are Being Reshaped

As the burden of industrial electricity rates increases in South Korea, more manufacturers are relocating their production bases to regions with lower electricity costs or building new factories overseas. Electricity rates are emerging as a key factor influencing plant locations, beyond being a simple cost item.

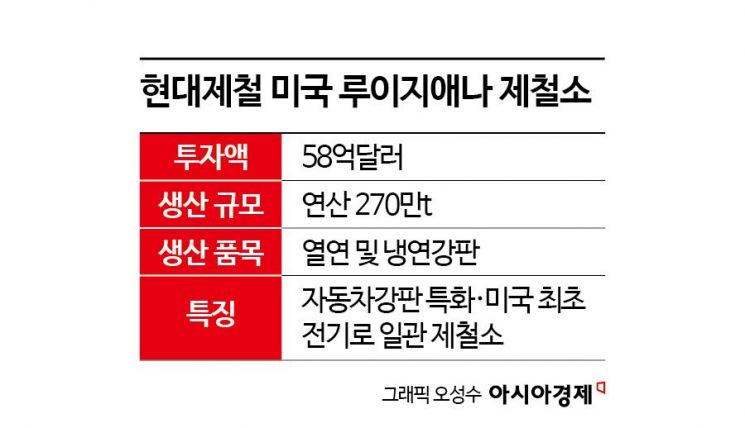

According to industry sources on January 19, energy costs played a significant role in Hyundai Steel's decision to select Louisiana as the site for its new electric furnace steel mill in the United States. Hyundai Steel, together with Hyundai Motor, Kia, and POSCO, is building an electric furnace steel mill in Louisiana with an annual production capacity of 2.7 million tons. The investment is approximately $5.8 billion (about 8 trillion won), with construction starting this year and operations targeted for 2029. Recently, the company also completed securing the plant site. Previously, when Korea Zinc decided to build a smelter in Tennessee, electricity rates were cited as a major factor, along with Korea-U.S. supply chain cooperation.

Carbon-reduction H-beams produced in Hyundai Steel's electric furnace, used as the framework for buildings. The Asia Business Daily DB

Carbon-reduction H-beams produced in Hyundai Steel's electric furnace, used as the framework for buildings. The Asia Business Daily DB

Electric furnaces are facilities that melt scrap metal or iron ore using electricity, and due to the nature of the process, they consume a massive amount of power. A Hyundai Steel representative stated, "Electricity rates in the U.S. vary greatly by region depending on the energy source for power generation. Louisiana has a high proportion of natural gas power generation, so electricity rates are relatively low. Since we are building an electric furnace, energy costs were a crucial factor in selecting the location."

In fact, the average industrial electricity rate in the U.S. is around $80 per MWh, while in Louisiana it is known to be in the low $50 range. This is less than half of the industrial electricity rate in South Korea. Additionally, relatively lower labor costs were also considered as a factor.

The conditions surrounding domestic factories are far from favorable. Steelmakers producing rebar and H-beams, which are mainly for the domestic market, have not been able to sufficiently raise their operating rates due to sluggish market conditions. In a situation where demand is weak, it is difficult to reflect higher electricity rates in production costs. A steel industry official said, "With high electricity rates and product prices remaining fixed, the burden inevitably increases. The trend of seeking overseas production bases due to energy cost issues is likely to accelerate in the future."

The petrochemical industry, which is also a heavy electricity user, is highly sensitive to electricity rates. OCI Holdings, whose main product is polysilicon, is maintaining profitability by leveraging relatively low electricity rates at its production base in Malaysia. Even with the same facilities and technology, profit structures differ depending on electricity rates, making energy costs a direct source of competitiveness.

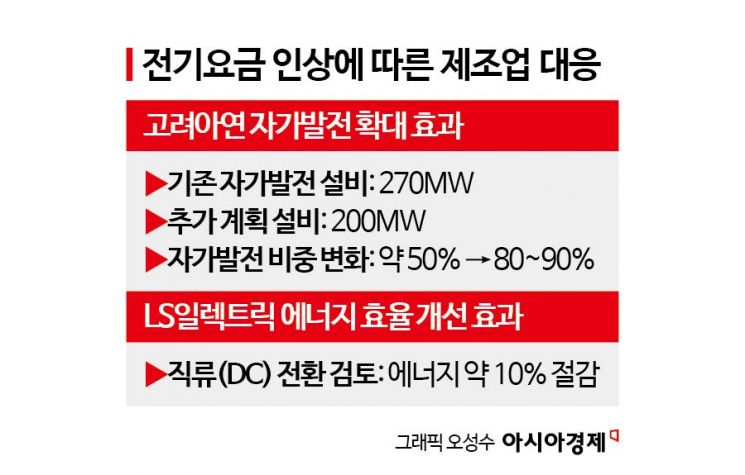

There is a strong sense among domestic manufacturers that the burden of electricity rates is accumulating. Moon Sangcheon, head of the LS Electric Cheonan plant, said, "The burden of electricity rates in the industry continues to accumulate every year. While higher electricity rates may benefit the revenue structure of state-run power companies, the burden inevitably increases for manufacturers who use the electricity."

As a result, companies are responding by trying to reduce their electricity consumption if they cannot lower electricity rates. LS Electric is considering converting its plant to direct current (DC) to improve energy efficiency. It is explained that switching to DC can reduce energy consumption by about 10%. Moon added, "A 10% reduction may seem small, but for facilities like factories that consume a lot of power, the cost difference is significant."

Even if there is an initial investment burden, efforts to increase energy self-sufficiency over the long term are spreading. Companies are attempting to directly manage their power usage by establishing distributed power sources or introducing energy management systems.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.