(From left) Yoon Junyeon, PhD candidate in the Department of New Materials Engineering at GIST (first author), Professor Eunji Lee, Dr. Junho Hwang.

(From left) Yoon Junyeon, PhD candidate in the Department of New Materials Engineering at GIST (first author), Professor Eunji Lee, Dr. Junho Hwang.

On January 6, the Gwangju Institute of Science and Technology (GIST) announced that a research team led by Professor Eunji Lee from the Department of New Materials Engineering has presented a new analytical paradigm. By integrating artificial intelligence (AI) with transmission electron microscopy (TEM) analysis, the team has expanded the study of complex self-assembled structures in "soft matter"-such as organic polymers and bio-materials-from mere "observation" to the stage of "automated analysis and prediction."

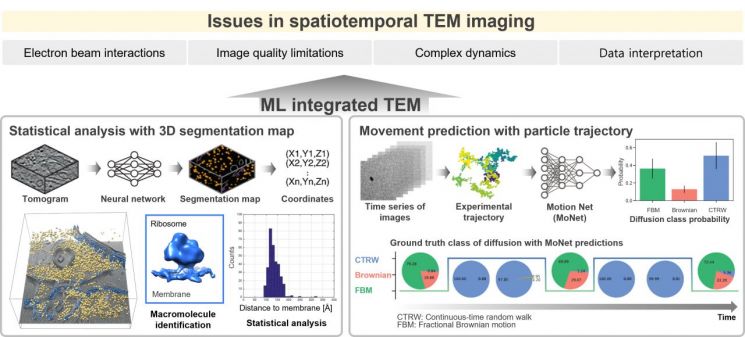

This research is noteworthy as it proposes an analytical framework that automates structure recognition, three-dimensional reconstruction, and temporal change analysis of complex self-assembled structures in soft matter-materials that are highly sensitive to electron beams and thus difficult to analyze. The framework integrates various electron microscopy techniques with AI, enabling not only automated structural analysis but also the prediction of material properties.

Soft matter encompasses a wide range of materials, from bio-materials such as proteins and cell membranes to synthetic materials like polymers and liquid crystals. These materials are gaining attention as key components in various advanced industries due to their "self-assembly" characteristics, where molecules spontaneously form fine nanostructures.

Such self-assembled structures are critical factors determining the performance of materials in next-generation vaccine delivery technologies (such as mRNA vaccine carriers), drug delivery systems, and next-generation energy storage materials. However, due to their extremely small and complex structures, there have been limitations in accurately observing and understanding them.

In particular, soft matter is mainly composed of light elements such as carbon, hydrogen, and oxygen, making it difficult to clearly distinguish structural outlines in electron microscopy images. Additionally, their structures are easily deformed or damaged by electron beams. As a result, conventional electron microscopy analysis alone has not been sufficient to precisely identify the unique nanostructures and self-assembly processes of soft matter.

Overcoming the Spatiotemporal Limitations and Achieving Precise Analysis of Soft Materials through AI-Integrated Electron Microscopy Technology.

Overcoming the Spatiotemporal Limitations and Achieving Precise Analysis of Soft Materials through AI-Integrated Electron Microscopy Technology.

To overcome these limitations, the research team combined deep learning-based AI technology with different electron microscopy techniques, including cryogenic electron microscopy (cryo-TEM), electron tomography (ET), and liquid-phase transmission electron microscopy (LP-TEM).

Through this approach, they implemented an integrated analysis strategy that enables: ▲ automated structural recognition of complex nanostructures; ▲ three-dimensional reconstruction of nanostructures from multiple two-dimensional electron microscopy images; ▲ automated dynamic analysis of the self-assembly process over time; and further, ▲ prediction of material properties based on structural information.

In this process, cryo-TEM captured the original nanostructures of soft matter with minimal damage; electron tomography was used to reconstruct these structures in three dimensions; and liquid-phase electron microscopy enabled real-time observation of self-assembly in solution, allowing for temporal analysis of structural formation and transformation.

By integrating AI, the research team was able to automatically process and interpret vast, high-dimensional electron microscopy data. This goes beyond simple image observation to establish an analytical system that elucidates the correlation between structure and material properties, and predicts future structural changes. This expands the role of electron microscopy from a "viewing tool" to a "tool for understanding and prediction," and is regarded as a significant achievement that suggests new research directions for the study of soft matter.

This research is academically significant as it demonstrates the potential to systematically understand the self-assembly mechanisms of soft matter by combining AI with electron microscopy analysis, and to move toward "image-based material design," where material properties are predicted from image data.

The research team plans to further advance the AI-based automated analysis system and apply it to the study of functional soft materials that operate reliably even under extreme conditions, with the goal of expanding into the biomedical and energy sectors.

Professor Eunji Lee stated, "This research is significant in that it established an analytical system capable of real-time observation of the self-assembly process of electron beam-sensitive soft materials, precise AI-based analysis, and even property prediction. It suggests a new research direction that extends beyond traditional image observation to data-driven material design."

Yoon Junyeon, PhD candidate (first author), said, "We focused on elucidating the correlation between nanostructures and material properties by analyzing vast, high-dimensional TEM data with AI. This study demonstrates that AI can become a core tool in 'materials informatics,' predicting material characteristics from electron microscopy images and proposing optimal material designs."

This research was conducted by PhD candidate Yoon Junyeon (first author) under the supervision of Professor Eunji Lee (corresponding author) from the Department of New Materials Engineering at GIST, with Dr. Junho Hwang from the GIST-InnoCORE Research Group participating as a co-author. The project was supported by the Mid-Career Researcher Program and the Nano and Material Technology Development Program of the Ministry of Science and ICT and the National Research Foundation of Korea, as well as the GIST-InnoCORE project. The research results were published online in the international journal 'NPG Asia Materials' on December 23 of last year.

Meanwhile, the research results have not only academic significance but also industrial application potential. Technology transfer discussions can be conducted through the Technology Commercialization Center.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)