Establishing a U.S. Production Base Leveraging Onsan Smelter Technology

Linked with Subsidiary Pedalpoint: From Raw Material Procurement to Production

Expanding Role Amid Restructuring of Critical Mineral Supply Chains

Korea Zinc's planned 11 trillion won smelter project in the United States is expected to become an overseas production base that connects its existing non-ferrous metal smelting operations with its resource circulation business. Korea Zinc's U.S. subsidiary, Pedalpoint, which recovers metal raw materials from electronic waste, plans to directly supply recycled raw materials to the U.S. smelter.

On December 17, Korea Zinc announced that it is reviewing a business structure that covers everything from raw material procurement to smelting and sales in relation to the construction of its smelter in Clarksville, Tennessee, which is being supported by both U.S. government investment and policy backing. The U.S. smelter has been designed based on the smelting technology and operational experience accumulated at the Onsan Smelter in Ulsan, South Korea. The company plans to utilize the new facility as a complex production base that manufactures both non-ferrous metals and strategic minerals, going beyond a single production line. Industry experts believe that the U.S. smelter will increase Korea Zinc's overseas production share and enhance its ability to respond to the North American market.

The core of the U.S. smelter project lies in its connection with local resource circulation businesses. In 2022, Korea Zinc acquired Ignio, a U.S. electronic waste recycling company, and established its subsidiary Pedalpoint, which now operates electronic waste processing and secondary raw material procurement businesses. According to the company, once the smelter is operational, raw materials secured by Pedalpoint will be supplied directly for smelting, establishing a structure in which both raw material procurement and production are carried out within the United States.

Pedalpoint processes printed circuit board (PCB) scrap and unused information technology (IT) assets, recovering valuable metals such as silver and copper. Recently, it has expanded its sourcing to include discarded solar panels, wafers, and waste batteries containing lead and nickel. Through Kataman, which handles non-ferrous metal trading, it is also securing copper scrap in parallel.

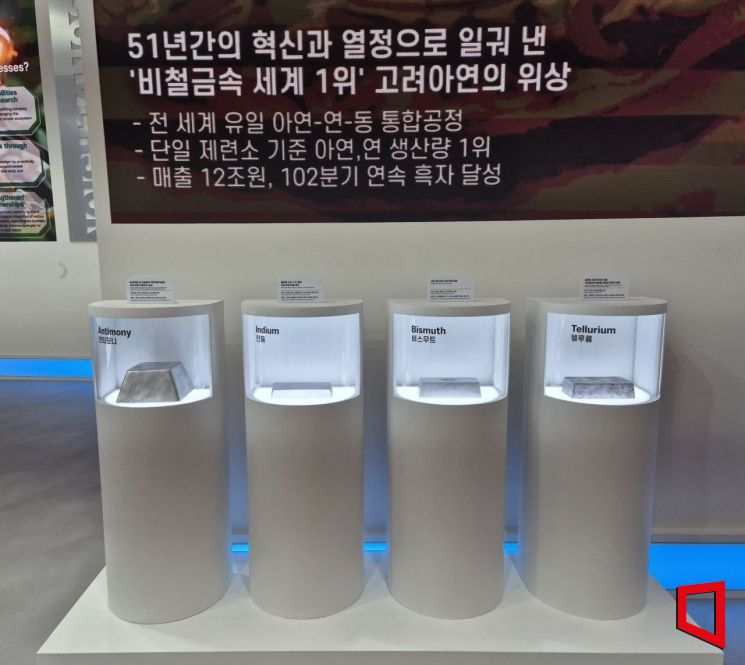

Going forward, Pedalpoint plans to increase its processing volume of discarded solar panels and waste lead-acid batteries. This will provide a foundation for supplying secondary raw materials needed to produce lead, silver, copper, antimony, and other metals at the U.S. smelter. The U.S. smelter aims to produce a total of 13 products, including base metals such as zinc, lead, and copper; precious metals such as gold and silver; and strategic minerals such as antimony, indium, bismuth, tellurium, palladium, gallium, germanium, and sulfuric acid for semiconductors. Many of these are designated as critical minerals by the U.S. government.

The expansion of the copper business will also proceed in parallel. Korea Zinc's annual copper production capacity currently stands at 31,000 tons, but is expected to increase to 150,000 tons by 2028. The Onsan Smelter will begin operating copper dry smelting facilities in 2026, and the U.S. smelter is scheduled to commence commercial production of copper products in 2029. As a result, the copper supply structure utilizing both domestic and overseas production bases is expected to expand gradually.

A Korea Zinc official stated, "The U.S. smelter is structured to carry out both raw material procurement and production in conjunction with local resource circulation businesses," adding, "This is significant for establishing a stable supply chain in the North American market."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)