EV Charging Speed Doubled

Low-Power LED Interior Lighting

On November 18 and 19, Hyundai Mobis held "Tech Bridge 2025" at the Hyundai Mobis Electrification Research Center in Uiwang, Gyeonggi Province, under the theme "Connecting Technology, Meeting Mobility." The company unveiled 50 new mobility technologies developed this year, with the aim of connecting automaker clients and parts suppliers through Hyundai Mobis's technology.

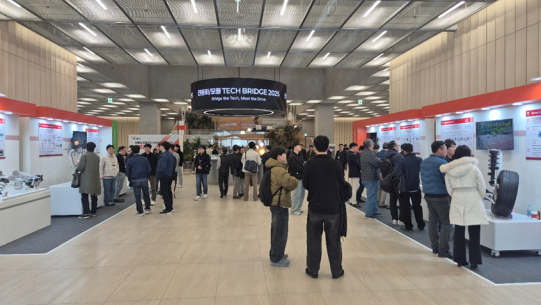

On the 18th and 19th, visitors are exploring 50 new electrification and module technologies at the "Tech Bridge 2025" event held at Hyundai Mobis Electrification Research Center in Uiwang, Gyeonggi Province. Hyundai Mobis

On the 18th and 19th, visitors are exploring 50 new electrification and module technologies at the "Tech Bridge 2025" event held at Hyundai Mobis Electrification Research Center in Uiwang, Gyeonggi Province. Hyundai Mobis

At this exhibition, Hyundai Mobis showcased 28 outstanding research and development (R&D) cases in the field of electrification, including batteries and drive components. A prime example is the 120 kW-class motor, power conversion, and battery (PE) system specialized for compact urban electric vehicles. It was designed with a low-floor structure that reduces volume and lowers the height of components, allowing for more cargo space so it can also be used as a transport vehicle.

The company also introduced a new technology that nearly doubles the charging speed of electric vehicles. The next-generation 22 kW-class Integrated Charging Control Unit (ICCU) enhances safety by monitoring the battery’s voltage and temperature in real time during high-speed charging.

On the 18th and 19th, visitors are exploring 50 new electrification and module technologies at the "Tech Bridge 2025" held at Hyundai Mobis Electrification Research Center in Uiwang, Gyeonggi Province. Hyundai Mobis

On the 18th and 19th, visitors are exploring 50 new electrification and module technologies at the "Tech Bridge 2025" held at Hyundai Mobis Electrification Research Center in Uiwang, Gyeonggi Province. Hyundai Mobis

In the module sector, a total of 22 new technologies were introduced. In the chassis module (the vehicle’s frame), low-floor technology that maximizes interior space utilization drew attention. In particular, the functionally integrated low-floor chassis module replaces the conventional steel coil springs and hydraulic shock absorbers with composite plate springs and an electric rotary damper, proposing a structure that improves both weight reduction and driving feel. Hyundai Mobis filed a total of five patents during the development of this technology.

In the cockpit module sector, the company presented technologies that enhance module manufacturability and manufacturing competitiveness, such as a low-power LED-based interior mood lighting controller that reduces vehicle power consumption while delivering high brightness, and a Wire Arc Additive Manufacturing (WAAM)-based injection mold technology that creates molds by welding and stacking metal, similar to a 3D printer.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)