A technology that can dramatically shorten the 'sintering' time of Solid Oxide Electrolysis Cells (SOEC) has been developed in South Korea.

SOEC is a core technology for producing green hydrogen (hydrogen produced by electrolyzing water using renewable energy such as solar or wind power). The production of green hydrogen requires a sintering process, in which ceramic powders are consolidated at high temperatures. However, the conventional sintering process required a temperature of 1,400 degrees Celsius for six hours, resulting in low efficiency.

(From the top left) Mechanical Engineering PhD candidate Hyungmin Yoo (top), Mechanical Engineering PhD candidate Seungsu Jang, (from the bottom left) Mechanical Engineering integrated MS-PhD candidate Donghoon Lee, Mechanical Engineering PhD candidate Gayoung Yoon, Mechanical Engineering Professor Kangtaek Lee. Provided by KAIST

(From the top left) Mechanical Engineering PhD candidate Hyungmin Yoo (top), Mechanical Engineering PhD candidate Seungsu Jang, (from the bottom left) Mechanical Engineering integrated MS-PhD candidate Donghoon Lee, Mechanical Engineering PhD candidate Gayoung Yoon, Mechanical Engineering Professor Kangtaek Lee. Provided by KAIST

On October 28, KAIST announced that the research team led by Professor Kangtaek Lee of the Department of Mechanical Engineering has developed an ultra-fast manufacturing technology that overcomes these limitations and enables the completion of high-performance electrolysis cells for green hydrogen in just 10 minutes.

The core of this technology, 'sintering,' is a process in which ceramic powders that make up the cell are fired at high temperatures to form a solid bond. This process must be carried out precisely to prevent gas leakage (as mixing hydrogen and oxygen can pose an explosion risk) and to ensure that oxygen ions can move without loss, thereby tightly adhering the electrodes and electrolyte to facilitate smooth current flow. In other words, the performance and lifespan of an electrolysis cell depend on the precision of the sintering process.

The research team succeeded in reducing the conventional sintering time from six hours to ten minutes by using 'volumetric heating' technology, which heats materials uniformly from the inside using microwaves (a method in which electromagnetic waves such as microwaves penetrate the material and the material directly absorbs energy, converting some of it into heat). They also demonstrated that stable electrolyte formation is possible at a reduced temperature of 1,200 degrees Celsius, compared to the previous 1,400 degrees Celsius.

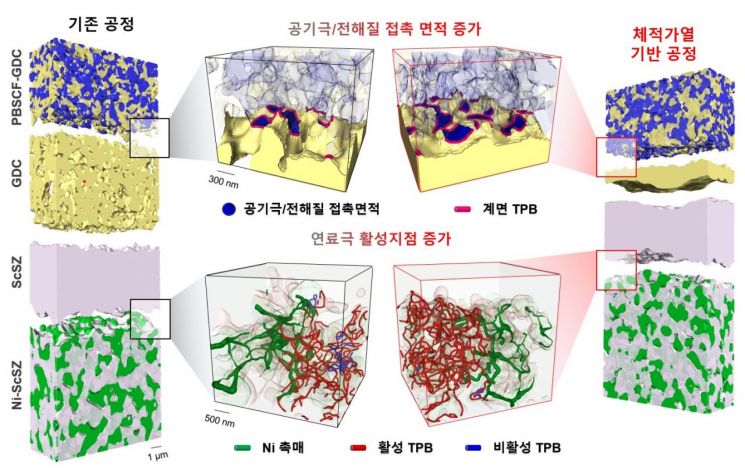

3D shape reconstruction, contact area, and electrochemical active site images of solid oxide electrochemical cells according to sintering process. Provided by KAIST

3D shape reconstruction, contact area, and electrochemical active site images of solid oxide electrochemical cells according to sintering process. Provided by KAIST

In particular, previous processes faced the problem of ceria (CeO₂) and zirconia (ZrO₂)-essential materials for the cell-mixing at high temperatures, which degraded the material quality. However, the new technology developed by the research team enables the two materials to bond firmly at an optimal temperature without mixing, resulting in a flawless, dense electrolyte layer.

The process time refers to the total manufacturing time required to complete a single cell, including heating, holding, and cooling steps. In conventional sintering processes, the total manufacturing time was 36.5 hours. According to the research team, applying microwave technology reduces the total manufacturing time to around 70 minutes.

Cells produced through this process are capable of generating 23.7 mL of hydrogen per minute at 750 degrees Celsius. The cells also demonstrated stable operation for more than 250 hours, along with excellent durability.

Additionally, through three-dimensional digital twin analysis (virtual simulation), the team found that applying the ultra-fast heating sintering process increases the density of the electrolyte (the material inside the cell) and controls the abnormal growth of nickel oxide (NiO) particles within the fuel electrode, thereby improving hydrogen production efficiency.

Professor Lee stated, "This research is significant in that it presents a new manufacturing paradigm for rapidly and efficiently producing high-performance solid oxide electrolysis cells. Compared to existing processes, it can dramatically reduce both energy consumption and time costs, increasing the potential for commercialization."

Meanwhile, Hyungmin Yoo and Seungsu Jang, PhD candidates in the Department of Mechanical Engineering, participated as co-first authors in this research. The results were recently published online in the international journal 'Advanced Materials.'

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)