Orion, Nongshim, and Samyang Expand Domestic Production Bases

Strengthening Global Expansion with K-Food Quality and Trust

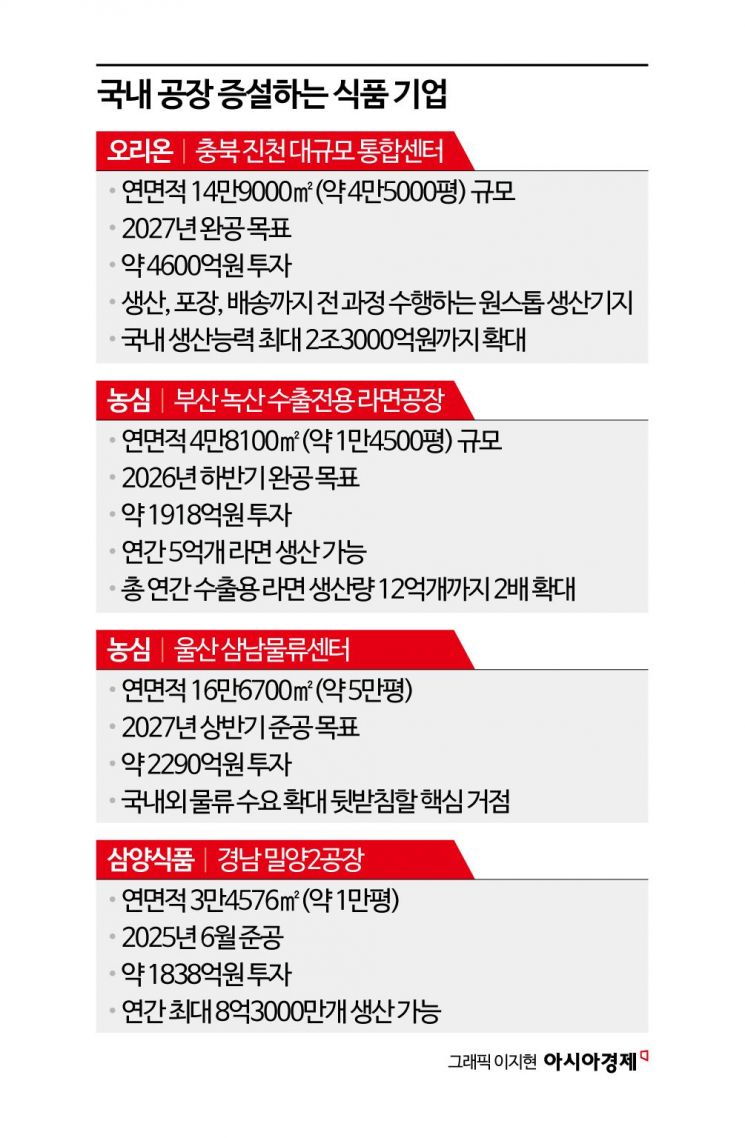

#On October 23, Orion broke ground for the "Orion Jincheon Integrated Center" at the Technopolis Industrial Complex in Jincheon County, North Chungcheong Province. Orion is investing approximately 460 billion KRW in the Orion Jincheon Integrated Center, which is being constructed on an 188,000-square-meter (about 57,000-pyeong) site-equivalent to 26 soccer fields-with completion targeted for 2027. Once completed, the Jincheon Integrated Center will increase Orion's domestic production capacity to as much as 2.3 trillion KRW. It will serve as a forward base for global exports targeting markets such as the United States and Europe, and will function as a one-stop production hub encompassing manufacturing, packaging, and delivery.

Domestic food companies are ramping up investments to expand their production facilities within Korea. As they seek to enter overseas markets, their strategy is to maximize brand trust and strengthen quality control by relying on domestic production bases rather than local manufacturing. This shift is influenced by the growing preference among overseas consumers for "Made in Korea" products, driven by the global enthusiasm for K-food.

According to the food industry on October 30, companies have recently been making large-scale investments in Korea to secure stable quality management and production efficiency amid a surge in export volumes.

Until now, food companies have expanded local factories as part of their overseas market entry strategies. This approach has allowed them to respond to rising local demand, reduce export costs such as logistics expenses, and more effectively target foreign consumers through localization. For example, Orion established its Beijing office in 1993 to enter the Chinese market, and in 1997, it completed a production plant in Langfang, Hebei Province, near Beijing. Orion later expanded its production facilities to Shanghai, Guangzhou, and other locations. Currently, Orion operates 11 factories across China, Vietnam, India, and Russia.

As of last year, Orion's domestic subsidiary posted sales of 1.1 trillion KRW (35%), while overseas subsidiaries accounted for a dominant 65% of total sales. With the domestic population shrinking, the Korean market's growth rate was just 2.6% last year-the lowest among Orion's subsidiaries worldwide.

Orion's decision to build a large-scale domestic production facility is driven by the fact that "Made in Korea" has become a kind of quality assurance mark among overseas consumers. The combination of Korea's strict hygiene standards, advanced manufacturing technology, and precise process management has established the perception that "Korean food products = trustworthy products."

Building new factories in Korea also offers the significant advantage of maximizing production efficiency and quality consistency by applying the latest automation systems. Higher electricity and labor costs compared to overseas are offset by adopting advanced technologies such as AI logistics systems, unmanned packaging lines, and energy-efficient facilities. This technological advancement is also regarded as a key indicator of a company's global competitiveness in future ESG (Environmental, Social, and Governance) evaluations.

Orion is not alone. Nongshim is also pursuing a two-track strategy by simultaneously constructing an export-only factory and a logistics center in Korea. The "Noksan Export-Only Factory" (scheduled for completion in the second half of 2026) at the Noksan National Industrial Complex in Busan and the "Ulsan Samnam Logistics Center" (scheduled for completion in the first half of 2027) within the Samnam Logistics Complex in Ulju County, Ulsan, are central to this plan. Once completed, the Noksan factory will operate three lines to produce 500 million packs of ramen annually, nearly doubling Nongshim's annual export ramen production to 1.2 billion packs when combined with the existing Busan factory (600 million packs) and Gumi factory (100 million packs). The Ulsan Samnam Logistics Center will serve as a "hub" supporting Nongshim's global logistics network.

In June, Samyang Foods completed its second factory in Miryang, located within the Nano Convergence National Industrial Complex in South Gyeongsang Province. This large-scale facility is equipped with six ramen production lines-three for packet noodles and three for cup noodles-and can produce up to 830 million packs of ramen annually. Samyang Foods is strengthening production of its export-oriented Buldak series, with the Miryang plant at its core.

Industry insiders say that as global demand for K-food continues to grow, companies plan to expand supply by building new factories and reinforcing production lines. While overseas investment will continue, they believe that expanding domestic production lines is a more efficient way to handle the rapidly increasing export volumes.

An industry official explained, "There is still a need to invest in local production bases to reduce logistics and tariff burdens, but companies must also consider the substantial upfront costs and unforeseen risks. Expanding domestic factories is a practical solution for stably handling export volumes."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)