Elon Musk Announces at Earnings Call

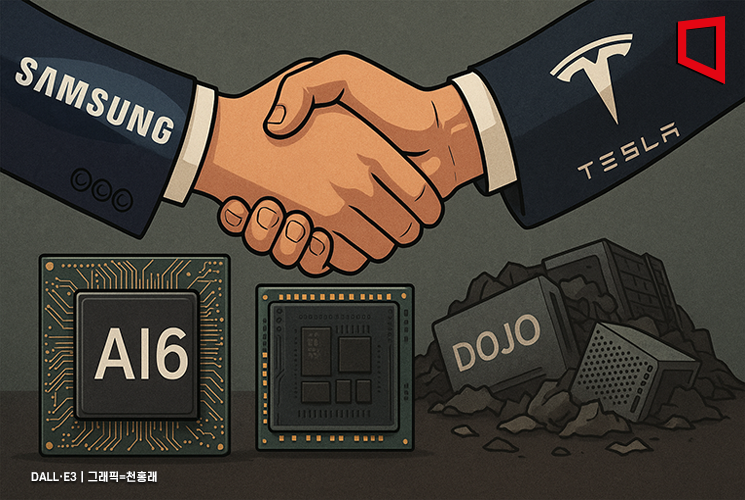

"Samsung to Work on AI5 Chip Alongside TSMC"

Secures Additional Orders Following 23 Trillion Won Deal

Mass Production Expected at Taylor, Texas Plant Using Sub-3nm Process

It has been confirmed that Samsung Electronics will newly participate in the development of Tesla's artificial intelligence (AI) chip 'AI5,' a project that had previously been exclusively entrusted to Taiwan's TSMC. As a result, following its recent achievement of securing a foundry (semiconductor contract manufacturing) deal worth approximately 23 trillion won from Tesla, Samsung Electronics has now acquired additional volume, providing significant momentum for improving the performance of its foundry business, which had previously posted multi-trillion-won losses each quarter.

On October 22 (local time), Elon Musk, CEO of Tesla, stated during a briefing following the company's third-quarter earnings report, "Both Samsung Electronics and TSMC will be working on the AI5 chip."

With this development, Samsung Electronics is now involved in all of Tesla's next-generation AI chips that have been recently developed or are being prepared for mass production. While Samsung Electronics had previously produced Tesla's AI4 chip, it was believed that starting with the AI5, production would be entrusted to TSMC. However, this announcement has changed the situation. Samsung Electronics had already received a mass production order for the next-generation AI6 chip in July. The AI4, AI5, and AI6 are AI chips developed in-house by Tesla for autonomous driving, and they are installed in vehicles to enable Full Self-Driving (FSD) functionality.

The cooperation between Samsung Electronics and Tesla has become even stronger with this latest announcement. Elon Musk, CEO of Tesla, has emerged as a savior for Samsung's foundry business, which had once been mired in losses and faced a crisis. Previously, on July 27, Musk revealed the large-scale foundry contract with Samsung Electronics via X (formerly Twitter), stating, "Samsung's large new plant in Texas will be dedicated to producing Tesla's next-generation AI6 chips. The strategic importance of this cannot be overstated." According to the announcement at that time and foreign media reports, the total value of the supply contract between Samsung Electronics and Tesla amounted to 22.7648 trillion won, making it the largest single-customer contract in the history of Samsung's semiconductor division.

Considering that the additional AI5 chips Samsung Electronics will now handle were originally scheduled to be produced at TSMC's U.S. plant using a 3-nanometer process, it is estimated that Samsung Electronics will also apply a similar process and mass-produce the chips at its advanced facility in Taylor, Texas. Samsung's Taylor plant is scheduled to begin operations next year. The AI4 chip is currently being mass-produced at Samsung Foundry's Pyeongtaek plant, while the AI6 chip is expected to be manufactured at the Taylor plant using an advanced 2-nanometer process.

The industry is watching closely to see whether Samsung's previously underperforming foundry business will find a breakthrough based on these contracts with Tesla. In its recent third-quarter provisional results, Samsung Electronics recorded 1.21 trillion won in operating profit, with the semiconductor business, particularly memory, showing signs of recovery. While the foundry business has narrowed its losses, it is still believed to be posting multi-trillion-won deficits. However, in the coming quarters, when the impact of Tesla's orders is fully realized, there is a strong possibility that the scale of these losses will be significantly reduced.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)