On-Site Coverage at Hanwha Systems Yongin Research Center's AESA Radar Testing Facility

Real-Time Tracking of Multiple Targets Possible with 1,000 Simultaneously Operating Modules

In 1935, a research team led by Robert Watson Watt in the United Kingdom succeeded in tracking an aircraft flying at an altitude of 300 meters and a distance of about 60 kilometers using electromagnetic waves. The U.S. Navy also utilized this technology. This marked the beginning of radar development. Since then, various radar technologies have been developed beyond just monitoring aircraft from the ground. Even supersonic fighter jets needed to be equipped with radars to detect various weapon systems on land and at sea. In 2012, when the South Korean government brought in the American stealth fighter F-35A through the next-generation fighter acquisition program (FX program), it requested a transfer of radar technology from the United States. The U.S. immediately refused. In response, the South Korean government decided to develop an Active Electronically Scanned Array (AESA) radar as part of the KF-21 fighter development project. Ultimately, South Korea succeeded in developing radar technology possessed by only 11 countries worldwide, including the United States, Israel, and Japan. Deployment will begin next year. To see the domestic radar technology firsthand, I visited the Hanwha Systems Yongin Research Center.

The AESA radar has undergone more than 200 tests in the air so far. Its performance was flawless. Last year, it received a "provisionally fit for combat" certification from the Defense Acquisition Program Administration and began mass production. Starting this year, the AESA radar will be sent to Korea Aerospace Industries (KAI) to be installed on the KF-21 fighter jet. (Photo by Korea Aerospace Industries)

The AESA radar has undergone more than 200 tests in the air so far. Its performance was flawless. Last year, it received a "provisionally fit for combat" certification from the Defense Acquisition Program Administration and began mass production. Starting this year, the AESA radar will be sent to Korea Aerospace Industries (KAI) to be installed on the KF-21 fighter jet. (Photo by Korea Aerospace Industries)

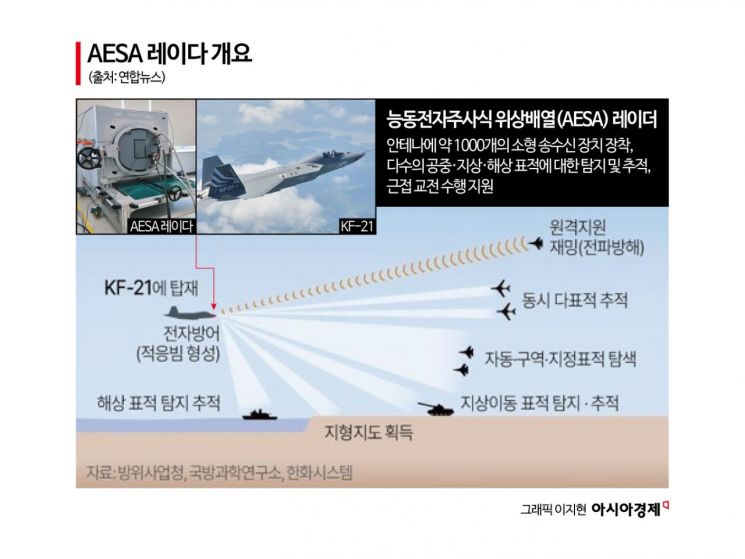

Radar works by emitting radio waves and measuring the time it takes for them to bounce back from a target, thereby determining the target's location, distance, and size. The radio waves from a radar travel only in a straight line. This is why traditional radars rotate 360 degrees to monitor all directions. However, the AESA radar developed by Hanwha Systems is equipped with about 1,000 modules that can each scan different angles. To use a human analogy, it is as if the radar has 1,000 eyes. Without rotating, each of the 1,000 modules can move independently, allowing the radar to detect multiple targets simultaneously. The processing speed is also extremely fast. On a fighter jet flying at Mach 1 (1,224 km/h), the radar processes information in microseconds (one-millionth of a second).

Radar is generally divided into an antenna unit, a transmit/receive processing unit, and a power supply unit. In the past, an additional computer was required. However, the AESA radar integrates the computer into the transmit/receive processing unit, reducing both size and weight. All core technologies were developed domestically. By developing the transmit/receive module (TRM) and amplifier (MMIC) for sending and receiving high-frequency (RF) signals, the unit cost was reduced by over 30% compared to imported products. Maintenance has also become easier.

Um Gwangsik, head of the Radar System Technology Team, said, "Each module of the AESA radar uses a different frequency, which allows it to avoid enemy jamming signals," adding, "It is the optimal radar for 'network-centric warfare,' where real-time information sharing is essential."

On the first floor, four electromagnetic test chambers known as anechoic chambers were operating simultaneously. As mass production of the AESA radar began, the number of test chambers was increased to shorten the testing period. Each monitor was displaying the calibration process for the AESA radar modules-aligning the focus of all 1,000 modules individually. It takes two months to calibrate a single AESA radar. The inner walls of the chambers were lined with hundreds of carbon fiber electromagnetic wave absorbers, resembling thorns on tree branches, to prevent interference from external electromagnetic waves during testing. The size of the absorbers varies depending on the frequency range. Higher frequencies have shorter wavelengths and greater directivity. When the radar operates for about an hour, its internal temperature can rise to 170 degrees Celsius. Since the radar heats up, coolant is used to dissipate the heat. When a fighter jet flies at high altitudes, the radar's temperature drops, so there is no need to worry. However, in extremely low temperatures, there can be concerns. The AESA radar is designed to operate normally in extreme environments ranging from minus 40 degrees to plus 70 degrees Celsius.

At the avionics simulation test site located on a hill at the Yongin Research Center, completed AESA radars were being tested. Aircraft flying over the Seoul metropolitan area were detected in real time. The AESA radar is equipped with an ultra-high-resolution Synthetic Aperture Radar (SAR). After a fighter jet strikes a ground target, it can provide real-time video to assess the damage. The AESA radar has undergone more than 200 tests in the air so far. Its performance was flawless. Last year, it received a "provisionally fit for combat" certification from the Defense Acquisition Program Administration and began mass production. This year, the first mass-produced AESA radar will be sent to Korea Aerospace Industries (KAI) to be installed on the KF-21 fighter jet.

Kim Seongtae, head of the Airborne Radar System Team, said, "Unlike ground-based radars, the AESA radar installed on the KF-21 fighter jet will be able to scan a wider area even at supersonic speeds," adding, "It will also enable the sharing of various information in conjunction with maritime and ground weapon systems."

The AESA radar is also gaining recognition overseas. In May last year, Hanwha Systems exported a "light attack aircraft AESA radar antenna" to the Italian defense company Leonardo. Hanwha Systems expects to be able to export AESA radars for light attack aircraft not only to Italy, which is part of Leonardo's supply chain, but also to other regions such as Europe and the Asia-Pacific.

Evolution continues. Fighter jet radars are currently cooled with coolant, but in the future, air cooling will be used. This is the "air-cooled" method, which will eliminate the space occupied by coolant inside the fighter jet. To use a monitor analogy, if mechanical radars were at the level of cathode ray tubes, AESA radars are comparable to light-emitting diodes (LEDs). In the future, AESA radars made with new materials instead of processed aluminum will be developed, reaching the level of organic light-emitting diodes (OLEDs). By reducing both size and weight, they will also be installed on unmanned aerial vehicles.

Park Hyuk, head of the DE Division at Hanwha Systems, said, "Last year, we secured the 'AESA radar technology development for unmanned wingman' project led by the Agency for Defense Development, and have begun production of the first air-cooled AESA radar in Korea," adding, "We plan to introduce new technology to the radar market."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)