Real-Time Detection of Thermal Runaway Risks Below 80 Degrees Celsius

(Front row from left) Professor Youngmin Song, Department of Electrical Engineering, KAIST; Professor Hyunho Jung, Department of Electrical, Electronics and Computer Engineering, GIST; (Back row from left) Researchers Joohwan Kim, Hyunmin Kim, and Joohyung Lee, Department of Electrical, Electronics and Computer Engineering, GIST.

(Front row from left) Professor Youngmin Song, Department of Electrical Engineering, KAIST; Professor Hyunho Jung, Department of Electrical, Electronics and Computer Engineering, GIST; (Back row from left) Researchers Joohwan Kim, Hyunmin Kim, and Joohyung Lee, Department of Electrical, Electronics and Computer Engineering, GIST.

A domestic research team has developed a technology capable of detecting the risk of electric vehicle battery fires in advance. By identifying early signs of internal battery abnormalities, this technology is expected to help prevent major accidents such as fires or explosions.

On September 24, the Gwangju Institute of Science and Technology (GIST) announced that a joint research team led by Professor Hyunho Jung from the Department of Electrical, Electronics and Computer Engineering at GIST and Professor Youngmin Song from the Department of Electrical Engineering at KAIST has developed a nano-optical temperature sensor. This sensor can detect the risk of thermal runaway in real time and intuitively alert users, even before the internal battery temperature reaches a dangerous level of 80 degrees Celsius.

Batteries are essential energy sources for advanced technologies such as electric vehicles, wearable devices, and urban air mobility (UAM). However, as fire and explosion accidents caused by thermal runaway continue to occur, safety concerns are becoming more prominent. In particular, when the internal battery temperature exceeds 80 degrees Celsius, key components such as electrolytes and separators begin to deteriorate, and the temperature can rapidly surge to over 500 degrees within one minute. Therefore, it is urgent to develop technology that can detect temperature early and provide timely warnings of danger.

Conventional temperature sensors can only measure areas in direct contact with thermocouples, making it difficult to grasp the overall temperature distribution. Infrared cameras also have limitations in accuracy depending on the surface material. In addition, existing technologies using thermochromic materials are unsuitable for real-time detection due to their slow response speed.

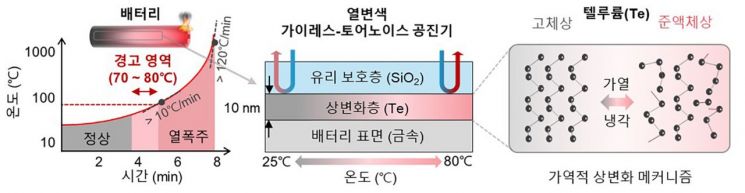

The research team focused on the unique optical modulation properties of tellurium, a mono-elemental material reported in the 1960s, and developed a thermochromic nano-optical device using an ultrathin tellurium film with a thickness of 10 nanometers (nm).

Tellurium partially melts from a solid to a quasi-liquid state as the temperature rises from room temperature to 80 degrees Celsius. It exhibits excellent optical modulation characteristics, with its refractive index changing by more than 0.7 in the visible light range, enabling ultra-fast temperature detection on the scale of one hundred-millionth of a second.

The researchers deposited an extremely thin 10-nanometer (nm) layer of tellurium (Te) on the surface of an aluminum-based battery, then laminated a protective glass (SiO2) layer several tens of nanometers thick on top, creating a Gires-Tournois resonator that changes its reflected color according to temperature. This resonator maximizes the optical property changes caused by the solid-to-quasi-liquid phase transition of tellurium even at relatively low temperatures below 80 degrees Celsius. The glass protective layer prevents damage to the tellurium from the external environment, ensuring stability. Furthermore, it operates without complex circuits or an external power supply and has a reversible property: when a certain temperature is reached, the color changes, then returns to its original state upon cooling back to room temperature.

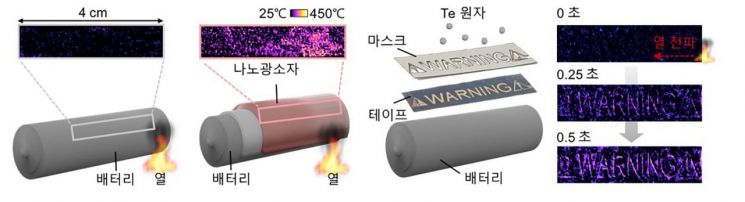

The fabricated nano-optical device can precisely distinguish temperature changes from room temperature (25 degrees Celsius) up to 80 degrees Celsius by color and demonstrates temperature detection performance comparable to commercial thermocouples. Furthermore, it visualizes the temperature distribution and heat diffusion process on the battery surface in real time at fast video frame intervals of 17 milliseconds (ms). It also reliably detects temperature even after dozens of heating-cooling cycles and under varying ambient humidity, and its thermochromic properties were shown to be maintained after nine months, demonstrating excellent durability.

The research team successfully demonstrated the practical applicability of the nano-optical device by monitoring heat generated during charging and discharging in real time when applied to commercial 18650 batteries and smartphones. This optical device can be directly deposited on battery cells or simply attached with tape, making it easy to introduce in industrial settings. Anyone can easily check the battery temperature status using only a smartphone or digital camera, without the need for specialized equipment or analysts, indicating a high potential for commercialization.

Professor Hyunho Jung of GIST stated, "By combining the optical modulation properties of tellurium with nanophotonics technology, we have secured a fundamental technology that can provide early warnings of battery explosion risks. In the future, it is expected to be utilized in various fields such as electric vehicles, aviation, space, firefighting, and wearable devices."

Professor Youngmin Song of KAIST said, "With recent battery fire incidents occurring both domestically and internationally, ensuring safety has become increasingly important. We expect this technology to present a new paradigm for next-generation battery safety and contribute to solving societal problems."

This research, supervised by Professor Hyunho Jung of the Department of Electrical, Electronics and Computer Engineering at GIST and Professor Youngmin Song of the Department of Electrical Engineering at KAIST, and conducted by GIST researchers Hyunmin Kim, Joohyoung Lee, Joohwan Kim, Gyurin Kim, Janghwan Han, and Joohwan Ko, was supported by the Excellent Young Researcher Program and Future Technology Research Laboratory Program of the Ministry of Science and ICT and the National Research Foundation of Korea, as well as the GIST-MIT AI International Collaboration Project. The results were published online in the renowned international journal in the field of materials, Advanced Materials, on July 23.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)