Construction robot technology has been developed to minimize the risk of fatal accidents at bridge construction sites, including the installation of bridge girders using robots. A girder is a beam that supports the deck slab and connects the piers of a bridge as part of its superstructure.

The Korea Institute of Civil Engineering and Building Technology (hereafter referred to as KICT) announced on the 11th that it has developed the "Remote Precision Installation Technology for Bridge Girders" and, for the first time in the world, has tested it at an actual bridge construction site.

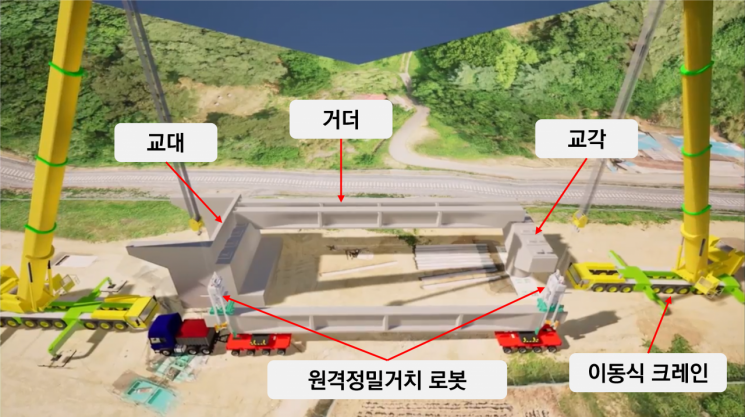

Overview of Remote Precision Installation Technology for Bridge Girders. Provided by Korea Institute of Civil Engineering and Building Technology

Overview of Remote Precision Installation Technology for Bridge Girders. Provided by Korea Institute of Civil Engineering and Building Technology

The construction industry is the sector with the highest frequency of fatal industrial accidents in South Korea. According to the Ministry of Employment and Labor, there were 584 fatal industrial accidents in 2023, of which 297 occurred in the construction industry, accounting for 50.9% of the total.

Last year as well, out of 553 total fatal accidents, 272 cases (49.2%) occurred in the construction sector. Nearly half of all fatal industrial accidents over the past two years have been concentrated at construction sites.

The Advanced Design and Construction Group at the Structural Research Division of KICT developed this technology to improve safety at construction sites (minimizing human casualties) by enabling robots to install bridge girders, which are key structural components, instead of humans.

The core of the technology developed by KICT is the installation of girders by remotely controlling precision installation robots through a ground-based remote control system. This eliminates the need for workers to climb to high places to install girders, fundamentally removing the risk factors for human casualties.

The "Remote Precision Installation Technology for Bridge Girders" is being tested at a bridge construction site. Provided by Korea Institute of Civil Engineering and Building Technology

The "Remote Precision Installation Technology for Bridge Girders" is being tested at a bridge construction site. Provided by Korea Institute of Civil Engineering and Building Technology

The bridge where the technology was tested on-site is a typical "girder bridge." Traditionally, workers had to manually adjust the position of the girders on top of piers or abutments.

However, with the Remote Precision Installation Technology for Bridge Girders, robots have replaced workers in adjusting the position of the girders, which, according to KICT, has fundamentally eliminated the risk of fatal accidents such as falls.

The Remote Precision Installation Technology for Bridge Girders was jointly developed by KICT, the Korea Institute of Robot and Convergence, SB Engineering Co., Ltd., and Dongil Technology Corporation.

KICT began conceptual design in 2020. In 2023, it partnered with Korea Expressway Corporation to test the technology on a testbed bridge, confirming its functionality and field applicability. This month, the technology was also tested at a bridge construction site provided by the National Railroad Authority.

During the field trial, the demonstration process combined SB Engineering's end-cut girder technology (product name "Ottugi Girder") with the Remote Precision Installation Technology for Bridge Girders.

The end-cut girder has a center of gravity lower than the bearing position, reducing the risk of overturning and eliminating the need for additional anti-overturning facilities after installation. According to KICT, combining the Remote Precision Installation Technology for Bridge Girders with the end-cut girder has further enhanced the technology's completeness and improved safety during the girder installation process.

Park Seonkyu, President of KICT, stated, "This field test is the world's first case of installing bridge girders using robots at a bridge construction site," adding, "We expect that unmanned high-risk operations will help create safer construction sites free from serious accidents."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)