A technology capable of capturing over 95% high-purity carbon dioxide using only a power supply at the level of a smartphone charging voltage (3V) has been developed. This technology is drawing attention as a potential "game changer" that could accelerate the transition to carbon-neutral processes, as it can be easily integrated with renewable energy sources such as solar and wind power.

On August 25, KAIST announced that a research team led by Professor Dongyeon Ko of the Department of Bio and Chemical Engineering, in collaboration with Professor T. Alan Hatton's team from the Department of Chemical Engineering at MIT, has developed the world's first "ultra-high-efficiency electrified direct air capture (e-DAC)" technology based on conductive silver nanofiber.

(From left) Professor Dongyeon Ko, Department of Bio and Chemical Engineering, KAIST; Professor T. Alan Hatton, Department of Chemical Engineering, MIT; Dr. Younghoon Lee. Provided by KAIST

(From left) Professor Dongyeon Ko, Department of Bio and Chemical Engineering, KAIST; Professor T. Alan Hatton, Department of Chemical Engineering, MIT; Dr. Younghoon Lee. Provided by KAIST

Direct Air Capture (DAC) is a technology that directly filters carbon dioxide present in the atmosphere at very low concentrations (below 400 ppm). Previously, the high energy cost was a major obstacle to the commercialization of DAC technology.

The DAC process requires high-temperature steam above 100 degrees Celsius to separate (regenerate) the absorbed and adsorbed carbon dioxide, and this step consumes up to 70% of the total energy, making energy efficiency crucial. For the same reason, complex heat exchange systems are essential, making it difficult to ensure economic viability.

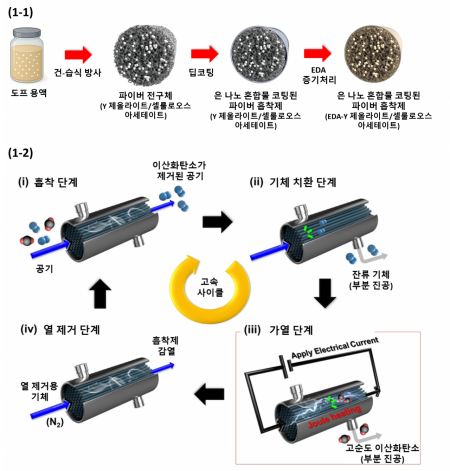

In contrast, this new research demonstrates the practical commercial potential of DAC. The joint research team addressed the energy cost issue by applying "self-heating fiber" technology, which heats up via electricity. By introducing the "Joule heating" method, which generates heat by directly passing electricity through the fiber-similar to an electric heating pad-they were able to precisely heat only the required areas without an external heat source, thereby reducing energy loss.

With this technology, the fiber can be rapidly heated to 110 degrees Celsius in just 80 seconds using a low voltage of only 3V. This significantly shortens the adsorption and regeneration cycle even in low-power environments and reduces heat loss (sensible heat) by about 20% compared to existing technologies.

The core of this research is not simply in creating an electrically conductive fiber, but in realizing a "breathable conductive coating" that enables both "electrical conductivity" and "gas diffusion" simultaneously.

The joint research team uniformly coated the surface of a porous fiber with a composite of silver nanowires and nanoparticles at a thickness of 3 micrometers, which is thinner than a human hair.

The resulting "three-dimensional continuous porous structure" provides pathways that allow both efficient electrical conduction and smooth movement of carbon dioxide molecules into the fiber, enabling uniform and rapid heating as well as efficient carbon dioxide capture at the same time.

Additionally, the team demonstrated that when multiple fibers are modularized and connected in parallel, the total resistance drops below 1 ohm, making it possible to scale up the system for large-scale applications. Using this approach, the joint research team successfully recovered over 95% high-purity carbon dioxide under actual atmospheric conditions.

The joint research team achieved these results after five years of research starting in 2020. Notably, by the end of 2022, they had completed Patent Cooperation Treaty (PCT) and domestic and international patent applications for the core technology, securing intellectual property rights. This indicates that the research has reached an advanced stage and that the technology is not only at the laboratory level but also has practical commercialization potential.

The fact that the device operates solely on electricity and can be easily integrated with renewable energy sources such as solar and wind power is cited as a key innovative advantage. This also aligns with the carbon-neutral process transition needs of global companies that have declared RE100.

Professor Dongyeon Ko stated, "DAC is not just a technology to reduce carbon dioxide emissions, but a core means to enable 'negative emissions' that purify the air itself. In particular, e-DAC can be widely utilized not only in industrial sites but also in urban systems, contributing to Korea's advancement as a leading nation in future DAC technology."

This research was led by Dr. Younghoon Lee, a PhD graduate from the Department of Bio and Chemical Engineering at KAIST (currently at the Department of Chemical Engineering, MIT), with Dr. Junghoon Lee and Dr. Hwajoo Joo from the Department of Chemical Engineering at MIT participating as co-first authors. The research findings were published online on August 1 in the materials science journal "Advanced Materials."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)