Manufacturing High-Efficiency Cathode Materials

by Suppressing Abnormal Particle Growth

with a Novel Sintering Process

A breakthrough core technology has been developed that can dramatically extend the lifespan of lithium-ion batteries.

The National Research Foundation of Korea (President: Hong Wonhwa) announced that a research team led by Professor Hyunwook Lee at Ulsan National Institute of Science and Technology (UNIST), in collaboration with Professor Rodney Ruoff and Dr. Sung Wonkyung at IBS, Professor Jin Sunghwan at Kangwon National University, and Professor Yuzhang Li at UCLA in the United States, has successfully proposed a new sintering process based on rapid Joule heating technology. This process enables precise control of microstructural defects in high-nickel cathode materials and significantly improves both lifespan and rate capability.

Research team, Professor Hyunwook Lee, Dr. Minho Kim (first author), Researcher Jungwoo Seo (first author). Provided by UNIST

Research team, Professor Hyunwook Lee, Dr. Minho Kim (first author), Researcher Jungwoo Seo (first author). Provided by UNIST

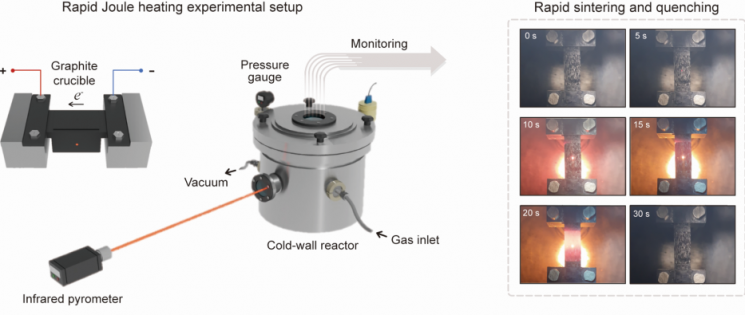

Rapid Joule heating technology is a method that instantly heats the material itself to a high temperature by passing an electric current through it. This allows battery materials to be rapidly densified while simultaneously suppressing particle growth.

Sintering is the process in which powder particles are thermally activated to form a single mass, while high-nickel cathode materials are next-generation lithium-ion battery materials with a nickel content of over 80 percent.

Rate capability refers to the slowest reaction step in a reaction system consisting of multiple stages, and the overall speed of the system is determined by the rate of this step.

High-nickel cathode materials are widely used in various fields, including electric vehicles and fast-charging batteries, as they are representative commercial battery materials capable of delivering high capacity and high energy density.

However, due to their low thermal stability, they are prone to structural and morphological degradation during high-temperature sintering processes.

The research team focused on the fact that excessive particle growth during high-temperature sintering and pore formation during low-temperature sintering are major causes of battery performance degradation. They analyzed the origins of these microstructural defects from the perspective of sintering dynamics.

Dynamics is a branch of mechanics that studies the forces acting on objects and the resulting motion (such as acceleration and changes in velocity). To address these issues, the team introduced a rapid Joule heating system capable of reaching high temperatures within seconds, utilizing a method that switches the dominant diffusion mechanism during the sintering process.

Through this approach, instead of particles coalescing into a single large mass, small particles were induced to densify closely together. This suppressed abnormal particle growth and the persistence of pores. As a result, both the lifespan and mechanical stability of the battery were dramatically improved.

This study demonstrated that mechanical densification plays a key role in enhancing the structural stability and lifespan of high-nickel cathode materials. By precisely controlling microstructural defects that occur during the thermal (sintering) process of high-nickel cathode materials, it is expected that long-life and highly reliable high-energy density batteries can be achieved.

Professor Hyunwook Lee stated, "This research is distinguished by not only changing the thermal treatment conditions but also by taking a fundamental approach to and empirical verification of the overall sintering behavior of cathode materials. It could be expanded as a foundational technology for optimizing the sintering process of various oxide-based electrode materials in the future."

This research was supported by the International Collaborative R&D Program for Core Technology, promoted by the Ministry of Science and ICT and the National Research Foundation of Korea. The results were published online in the international journal Advanced Materials on August 4.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)