From "Invisibility Cloaks" to Next-Generation Communication:

How Artificial Structures Are Transforming Our World

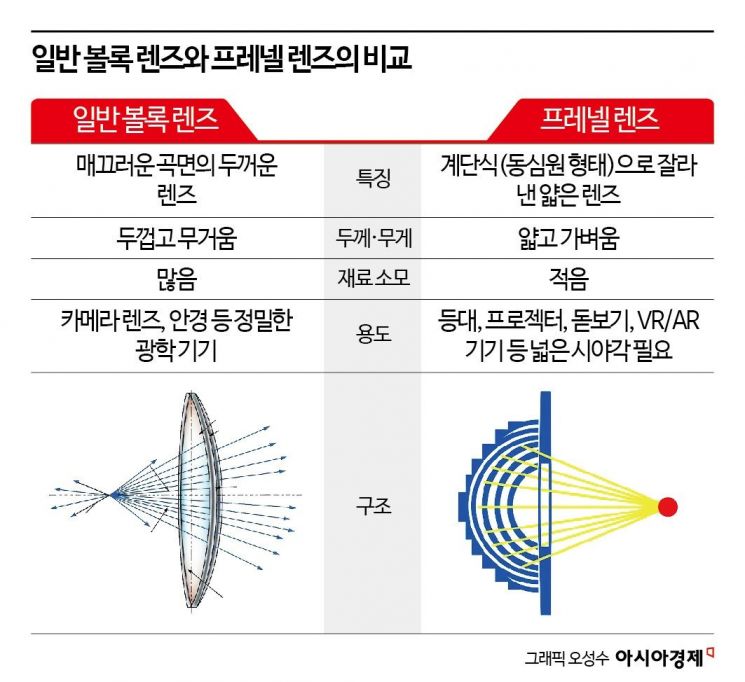

In the early 19th century, France was searching for ways to make lighthouse beams reach farther and shine brighter. At that time, convex lenses used for lighting were heavy and expensive, and increasing their performance required making them even thicker.

A young physicist, Augustin-Jean Fresnel, approached this problem from a completely different angle. He invented the Fresnel lens by removing all but the surfaces essential for refracting light, cutting away the rest in a stepped pattern. This was an idea that enhanced performance not by changing the material or the laws of physics, but by altering the shape and structure.

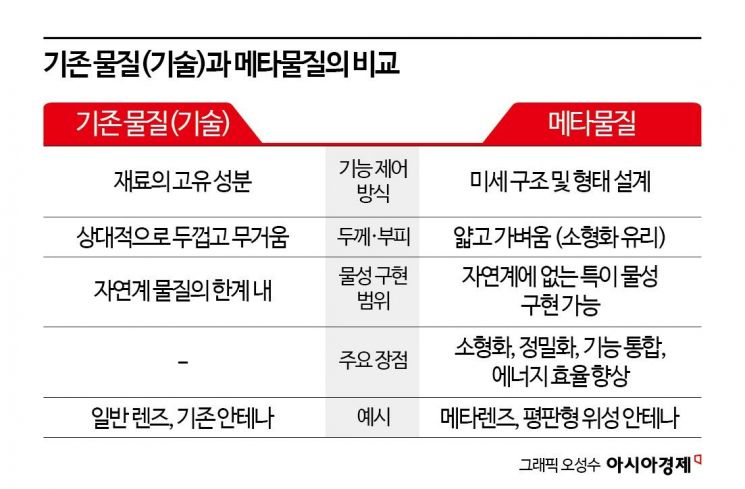

Since then, scientists have expanded the possibility that the function of a material can be changed solely through structural design to a broader range of fields. 'Metamaterials' are a representative example. These are artificially engineered structures designed at a microscopic scale to manipulate wave properties such as light, sound, electromagnetic waves, and heat.

The key lies not in the composition of the material, but in the microstructures arranged at scales smaller than the wavelength. These structures affect the propagation of waves, giving rise to new physical properties such as refractive index, reflectivity, and permeability. This technology mathematically designs the spatial form to change the response of the material, rather than simply relying on its composition.

Controlling Waves Through Shape: 'Thinner and Stronger'

Hong Seonghun, a researcher at the Smart Materials Research Laboratory of the Electronics and Telecommunications Research Institute (ETRI), explained, "Metamaterials are artificially engineered substances that can realize unique physical properties not found in nature. By adjusting structure, shape, and arrangement, one can tailor the properties of the material as desired." For this reason, metamaterials are attracting attention in various technological fields, as they can reduce weight and volume while improving performance.

In 2006, the research team of Professor David Smith at Duke University in the United States, along with Professor John Pendry in the United Kingdom, successfully demonstrated the principle of an 'invisibility cloak' by using metamaterials to reroute microwaves of specific frequencies. This brought the concept of metamaterials to the attention of the general public.

Metamaterials first showed practical potential in the field of optics. Traditional lenses refract light through thick glass, but metalenses focus light using surface structures designed at the nanometer scale.

This method enables the creation of thin and lightweight lenses, which is advantageous for miniaturizing smartphone cameras, AR/VR devices, and wearable displays. In display technology, it is possible to selectively transmit or reflect only specific wavelengths of light, allowing for the production of high-resolution OLED, QLED, and hologram displays.

Metamaterials are also effective in altering the propagation path of electromagnetic waves. The angle and intensity at which radio waves pass through or reflect off a material can vary greatly depending on its internal structure. By precisely designing this structure, metamaterials can bend radio waves in one direction or focus them in a specific direction.

This technology has significant potential in communication fields such as satellite communications, wireless transmission and reception, and high-sensitivity antennas for 6G communications. In fact, the American private company Kymeta has commercialized flat-panel satellite antennas using metamaterials, enabling stable satellite signal reception even while ships and aircraft are in motion.

Technology That Bends Light, Changes the Direction of Electromagnetic Waves, and Controls Energy

In the defense sector, metamaterials are being applied to stealth technology by absorbing electromagnetic waves or reducing scattering. They are being considered as practical alternatives for electromagnetic shielding materials, radar absorbers, and materials that block wireless signal interference.

Metamaterials are also advancing energy efficiency and precision control technologies. Physical quantities with wave properties, such as heat and sound, can also be controlled. Like light, heat and sound are reflected or absorbed depending on wavelength, and their transmission paths change according to structure. By precisely designing microstructures, it is possible to control heat and acoustics in ways that are difficult to achieve with conventional materials.

The field that first demonstrated the practical potential of metamaterials is optics. Metalenses can realize thin and lightweight lenses. They are advantageous for miniaturizing smartphone cameras, AR and VR devices, and wearable displays. Provided by Pixabay

The field that first demonstrated the practical potential of metamaterials is optics. Metalenses can realize thin and lightweight lenses. They are advantageous for miniaturizing smartphone cameras, AR and VR devices, and wearable displays. Provided by Pixabay

In solar panels, filter structures that block infrared and ultraviolet rays while allowing only visible light to pass through can reduce overheating and degradation, thereby increasing power generation efficiency. In building windows or heat-dissipating materials inside electronic devices, unnecessary energy loss can be prevented and thermal control performance can be improved.

Acoustic metamaterials can block or distort specific frequencies of sound, making them inaudible. This technology can be applied to soundproofing systems, high-sensitivity acoustic sensors, and customized sound filtering devices. There is also ongoing research on technologies that precisely control mechanical shocks or vibrations by altering the transmission path of vibrations.

New possibilities are also emerging in the medical and bio fields. Because metamaterials can selectively amplify or focus waves of specific frequencies, they enable the creation of high-sensitivity sensors that detect very subtle biological signals or pathological changes. This allows for more precise identification of trace amounts of viruses, cancer cells, or disease markers compared to conventional methods, and can be applied to early and precision diagnostic technologies.

By focusing light, heat, or sound waves only on targeted areas, it is possible to selectively stimulate or destroy lesions, which is advantageous for minimally invasive procedures or targeted therapies. There is also research on designing metamaterial structures that release specific drugs only when certain conditions are met inside the body. This technology, known as smart drug delivery systems, can improve drug efficacy and reduce side effects.

POSTECH Accelerates Commercialization Through Manufacturing Innovation

Although metamaterials are still in the early stages of commercialization, Korea is showing outstanding competitiveness, especially in the field of manufacturing technology. The research team led by Professor Roh Joonseok at Pohang University of Science and Technology (POSTECH) has developed a mass production process for metalenses, accelerating the realization of compact, high-performance optical devices.

Because metamaterials require the precise arrangement of nanometer-scale structures, traditional processes resulted in excessively high production costs. In fact, as recently as 2019, a single metalens for cameras cost as much as 5 million won (4,000 dollars).

However, Professor Roh's team dramatically reduced manufacturing costs by adapting semiconductor processes, and has now established a foundation for producing metalenses at less than 10,000 won (8 dollars), which is cheaper than conventional optical systems.

Professor Roh emphasized, "We have a technology that enables the mass production of metalenses at a dramatically lower cost than conventional refractive optical systems. This is a leading technology that only our laboratory can offer worldwide."

He added, "With support from POSCO, POSTECH and the Research Institute of Industrial Science and Technology (RIST) have completed the technology for mass-producing metalenses, and we are receiving collaboration requests from companies and research institutes around the world. We are pursuing practical applications in various fields, including augmented reality glasses, ultra-miniature cameras, and hologram displays."

Korean companies such as Samsung Electronics and LG Electronics are also paying attention to the potential of metamaterials in fields such as 6G communications, next-generation displays, and high-sensitivity sensors. Research to verify the technology through industry-academia cooperation and explore the possibilities for actual product applications is also increasing.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)