Design Flexibility, Production Efficiency, Structural Stability, and Maintenance Convenience

Development of Seven Types Including Passenger, Cargo Compact, and High Roof

On July 17, Kia announced that it will officially enter the PBV (Platform Beyond Vehicle) market, which stands for "a platform beyond just a vehicle," with "The Kia PV5" that features next-generation body technology called the "Flexible Body System."

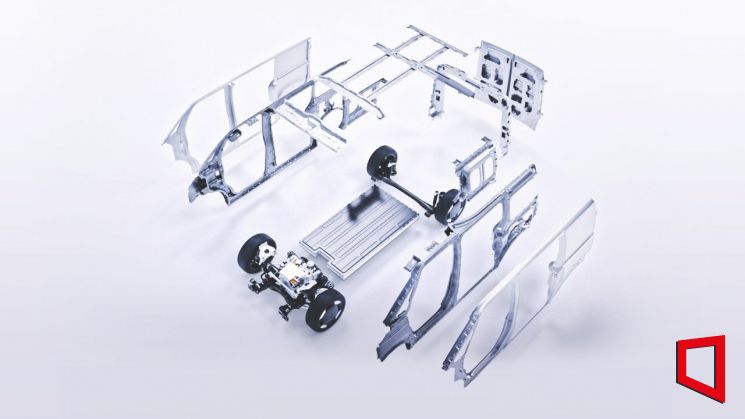

The Flexible Body System is a specialized technology that enables the development and production of various vehicle specifications by modularizing major components such as the body, doors, tailgate, exterior, and interior, in a "block-like assembly" manner. This system secures design flexibility and production efficiency optimized for multi-variant vehicle development, as well as structural stability of the body and ease of maintenance.

The PV5 features a standardized front and first-row structure across all models, while the sections after the first row and the rear can be selectively combined by modularizing body and exterior components such as the rear overhang, tailgate, quarter glass, and roof. Kia has established a system that can expand the PV5 body lineup to up to 16 variants. As a first step, the company has developed seven basic body types: Passenger (Long), Cargo Compact (3- and 4-door), Cargo Long (3- and 4-door), and Cargo High Roof (3- and 4-door).

For example, the PV5 Cargo Long is produced by moving the "rear overhang module" of the Cargo Compact to the back and adding a "long body module" between the D-pillars to extend the overall length. By simply replacing the quarter glass module and the tailgate module, it can be converted to a Passenger body.

Kia has also applied the "assembled rear side around garnish" and "external ring structure" to flexibly and quickly respond to customer needs while ensuring safety and ease of maintenance.

The assembled rear side around garnish is applied to the outer side of the body after the D-pillar. Made from a plastic composite that is easier to mold than typical steel panels, it can be produced and applied in various sizes and shapes depending on the vehicle's length, height, and intended use. The garnish is composed of three pieces, allowing only the damaged part to be easily replaced in the event of a rear collision or scratch, thereby improving maintenance convenience and reducing repair costs.

In addition, by applying an external ring structure that thickens the body frame to the outside, Kia has enhanced the structural stability of the body as well as noise, vibration, and harshness (NVH) performance.

Kia has also applied the Flexible Body System to the interior of the PV5, enabling a variety of uses. The luggage side trim located in the trunk space is available in seven types according to the body specification and customer needs, supporting a user-customized space configuration that can accommodate various accessories such as Kia Adgear.

Kia plans to begin mass production of the PV5 Passenger 5-seater and Cargo Long models this month and will sequentially introduce various models. In 2027, the company will expand its product portfolio by launching a large-size PBV.

Lee Youngho, Executive Vice President of MSV Body Design 1, who led the development of the Flexible Body System, said, "The block-type modular assembly concept, which is different from the conventional approach, was a challenging task at first, but ultimately became a turning point for a new vehicle development method suitable for the PBV era. We will continue to pursue technological innovation to effectively provide customized vehicles that can respond to customers' diverse lifestyles and changing business environments."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)