Participation in Gangwon-Chuncheon Hub Complex

Establishing a Mass Production System for Insects such as Mealworms

Plan to Present the 'K-Insect Standard Model'

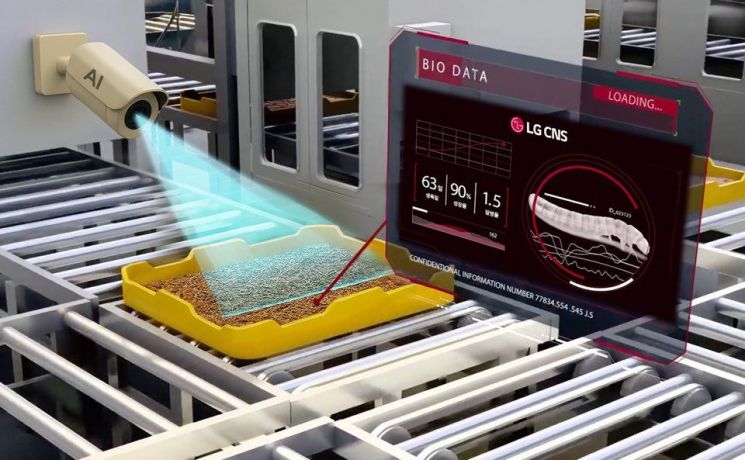

"Artificial intelligence (AI) analyzes the color and movement of insects, automatically sorting sick or dead specimens to the left and marketable ones to the right."

LG CNS has been selected to lead the construction of the insect smart factory farm within the Gangwon-Chuncheon Insect Industry Hub Complex, a project with a budget of 20 billion won. By utilizing vision AI technology that analyzes visual data, the company will digitalize and automate the production process without human intervention. LG CNS plans to complete the construction of the smart factory farm by the end of this year and begin mass production starting next year.

Kim Honggeun, Vice President of LG CNS (far right), is conducting the groundbreaking ceremony for the smart factory farm within the insect industry hub complex on the 16th, along with key figures including Kim Jintae, Governor of Gangwon Province (center), and Yuk Donghan, Mayor of Chuncheon (fifth from the right). Provided by LG CNS

Kim Honggeun, Vice President of LG CNS (far right), is conducting the groundbreaking ceremony for the smart factory farm within the insect industry hub complex on the 16th, along with key figures including Kim Jintae, Governor of Gangwon Province (center), and Yuk Donghan, Mayor of Chuncheon (fifth from the right). Provided by LG CNS

As AI transformation (AX) accelerates across all industries, it has now reached the insect industry, which is considered a promising future growth sector. Insect production is recognized as a high-potential industry due to its scalability and connections to various fields such as food, feed, and bio-materials. An LG CNS representative stated, "By integrating AX capabilities into the traditionally small-scale insect production process, we will increase output and enhance operational efficiency."

On July 16, LG CNS participated in the groundbreaking ceremony for the Gangwon-Chuncheon Insect Industry Hub Complex, hosted by Gangwon Special Self-Governing Province, officially launching the insect smart factory farm construction project. The ceremony was attended by Kim Jintae, Governor of Gangwon Province, Yuk Donghan, Mayor of Chuncheon, Kim Honggeun, Vice President of LG CNS, and other key executives.

The insect industry hub complex to be built in Chuncheon, Gangwon Province, will be an advanced smart factory farm capable of mass-producing insects such as mealworms. LG CNS will be responsible for the AX-based production operation management and integrated control system, the AI growth management system, and the automation of insect breeding, feed manufacturing, and environmental control facilities.

LG CNS has previously established AI-based intelligent smart factories across various industries, including electronics, batteries, and pharmaceuticals. The company will now apply its accumulated manufacturing AX technologies, such as quality selection and precision control, to the insect production process. By the end of this year, LG CNS aims to complete the insect smart factory farm and implement a large-scale automated mass production system capable of producing approximately 700 tons of mealworms annually.

LG CNS announced on the 16th that it will implement an automated insect mass production system producing 700 tons of mealworms annually by utilizing vision artificial intelligence (AI) technology that analyzes and interprets visual data. The photo shows a conceptual image of the insect smart factory farm service to be established in Chuncheon, Gangwon Province. Photo by LG CNS

LG CNS announced on the 16th that it will implement an automated insect mass production system producing 700 tons of mealworms annually by utilizing vision artificial intelligence (AI) technology that analyzes and interprets visual data. The photo shows a conceptual image of the insect smart factory farm service to be established in Chuncheon, Gangwon Province. Photo by LG CNS

LG CNS will maximize insect quality and production volume through its AI growth management system. Previously, removing sick or dead insects required manual labor, making quality control difficult when the number of specimens reached thousands or tens of thousands, thus limiting large-scale breeding. To address this, the company will use vision AI technology to monitor the growth stages of insects, determine the optimal shipping time, and analyze color and movement in real time to identify defective specimens.

Together with Gangwon Province, LG CNS plans to present the 'K-Insect Standard Model' that will lead the future of the insect industry. The company will fully localize the insect breeding platform and integrate all manufacturing master data?including codes, terminology, and indicators?into standardized management, enabling flexible expansion when establishing new factories in the future.

LG CNS has now acquired smart farm innovation capabilities that extend beyond plants to insects. Previously, the company built the intelligent platform for the 160,000-pyeong Advanced Unmanned Automated Agricultural Production Demonstration Complex in Naju, Jeonnam Province. This smart farm service analyzes various agricultural data such as soil, weather, and pest outbreaks using AI to provide optimal farming methods, and deploys digital scarecrows that use AI to detect and repel harmful birds and animals. Vice President Kim stated, "We will contribute to making this insect smart factory farm a beacon factory for the future K-insect industry."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)