China's Absolute Dominance in Core Materials

Over 85% Market Share in Anode Materials, Electrolytes, and More

South Korea's leading battery material companies are losing competitiveness as their global market share declines. While cell manufacturers are maintaining their positions, the materials sector remains heavily dependent on China, raising concerns about the stability of the secondary battery industry's supply chain.

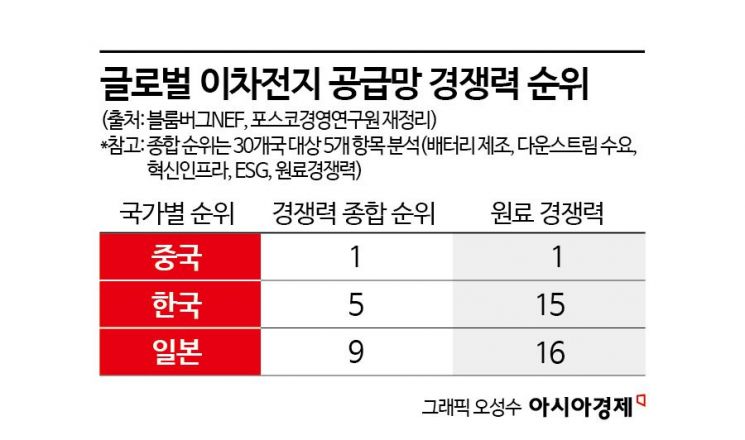

According to BloombergNEF data reorganized by the POSCO Research Institute on July 3, South Korea ranked 15th in raw material competitiveness. China ranked first, and Japan ranked 16th. In the overall national competitiveness rankings, which combine battery manufacturing, demand, innovation infrastructure, and ESG (environmental, social, and governance) competitiveness, South Korea was ranked fifth.

China's dominant influence in the core materials sector remains unchanged. As of 2023, China held a market share of over 85% in all three key global battery material markets: anode materials, electrolytes, and separators. The gap is even more pronounced in the anode materials market. For graphite, a key material, China accounts for 67% of raw material mining, 99% of intermediate material production, and 94% of final material production. Unlike lithium or nickel, the processing cost of graphite makes up a much higher proportion than the raw material cost, so processing outside of China is not economically viable. As a result, China effectively monopolizes the graphite value chain.

In contrast, South Korea's leading material companies have only achieved single-digit market shares. POSCO Future M's anode materials hold a 2.4% share, Enchem's electrolytes account for 4.6%, and SK IE Technology's (SKIET) separators have a 2.9% share. All four of South Korea's leading companies, including Ecopro BM, recorded losses last year, and the outlook for performance improvement this year is also bleak.

An industry insider stated, "There is a significant gap with China in every factor that makes up material costs, including electricity, labor, and raw materials," adding, "It is difficult for companies to secure price competitiveness through their own efforts alone." The insider continued, "After Japan lost its leadership in the secondary battery sector, the government stepped in with large-scale subsidies to build up the supply chain. South Korea should not rely solely on the private sector and must also actively support the industry through policy measures."

Park Jaebeom, a senior researcher at the POSCO Research Institute, said, "What is needed now are policies that can be felt in practice," and added, "Companies should be able to receive tax refunds on their investments, and temporary subsidies for electricity and rent are also necessary." Park further emphasized, "It is time to strengthen the foundation of domestic material competitiveness by expanding infrastructure within secondary battery industrial complexes, easing regulations on water supply and wastewater treatment, and increasing support for overseas resource development investments."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)