Successful Development of a High-Efficiency, High-Durability Artificial Photosynthesis Module

Artificial Leaf Technology Produces Green Hydrogen Using Solar Energy

Research results have been released that significantly increase the commercial viability of artificial photosynthesis technology, which directly converts solar energy into hydrogen.

A new artificial leaf module has been developed that meets all requirements for high efficiency, long-term stability, and scalability. This is considered a major advancement in green hydrogen production technology for achieving carbon neutrality.

The research team led by Professors Lee Jaesung, Seok Sangil, and Jang Jiuk from the Department of Energy and Chemical Engineering at UNIST developed a "modular artificial leaf" featuring high efficiency, high durability, and large-area scalability.

Research team, (from right) Professor Lee Jaesung, Dr. Dharmesh Hansora (first author), Researcher Noh Eunseo (first author), Dr. Rashimi Merotra (first author), Professor Jang Jiuk, Dr. Byun Woojin. Provided by UNIST

Research team, (from right) Professor Lee Jaesung, Dr. Dharmesh Hansora (first author), Researcher Noh Eunseo (first author), Dr. Rashimi Merotra (first author), Professor Jang Jiuk, Dr. Byun Woojin. Provided by UNIST

The "artificial leaf" is a technology that produces hydrogen using only sunlight and water, just like a natural leaf. It does not require any external power supply and does not emit carbon dioxide during hydrogen production, making it a green hydrogen production method. Unlike conventional photovoltaic-electrolysis (PV-EC) methods, which require a separate electricity generation step, this structure directly converts light energy into chemical energy, resulting in lower losses due to system resistance and reduced installation area. However, commercialization has been limited due to issues such as low efficiency, insufficient durability, and scalability challenges.

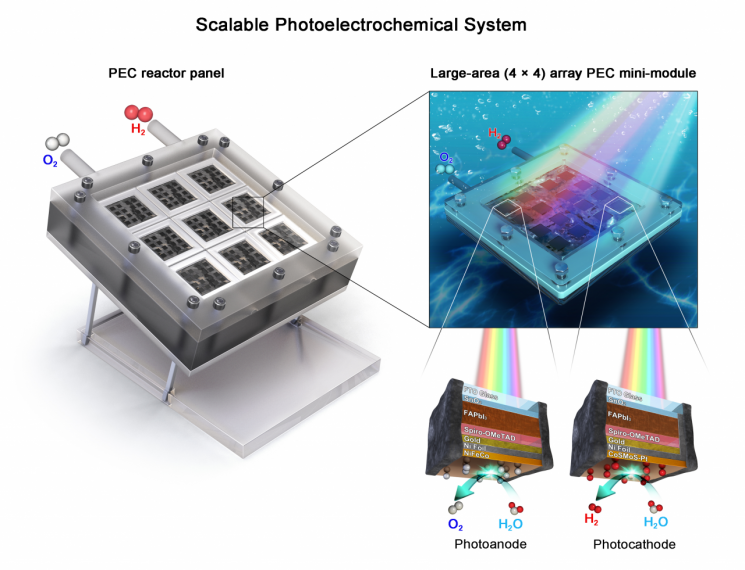

The research team fabricated a high-efficiency photoelectrode with a perovskite-based solar absorber and a nickel-iron-cobalt catalyst in 1 cm² units, then expanded this into a modular artificial leaf with a 4×4 array. This module can stably produce hydrogen using only sunlight, without any external power source, and achieved a solar-to-hydrogen (STH) conversion efficiency of 11.2% at the module level.

This is the highest level ever reported for artificial leaves to date, and it is significant that the module achieved an efficiency of over 10%, which is the threshold required for commercialization.

The research team attributed the high efficiency and stability to the combination of a chlorine-doped perovskite absorber layer (Cl:FAPbI₃), an ultraviolet-resistant electron transport layer (Cl:SnO₂), and a catalyst layer (NiFeCo).

Additionally, to prevent moisture-induced damage to the electrodes, the team applied a special nickel foil and resin encapsulation technology, allowing the module to maintain 99% of its initial performance even after 140 hours of continuous operation.

Professor Lee Jaesung stated, "This achievement goes beyond simply producing hydrogen efficiently in the lab. It is significant because the modular artificial photosynthesis device reached the commercialization standard of over 10% efficiency, making it suitable for real-world applications. Furthermore, it can be expanded into large-area artificial leaf panels like solar panels, marking a decisive step forward toward commercialization."

This research was published in the world-renowned journal Nature Communications (IF: 14.7) on May 6, 2025, and was supported by projects such as the Climate Change Response Project and BrainLink Project promoted by the Ministry of Science and ICT, as well as the IBS Basic Science Research Support Project.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)