(From left) Dr. Yongryun Cho, Professor Gunhyung Ahn from Dongguk University, Student Heeyeon Heo from Gyeongsang National University

(From left) Dr. Yongryun Cho, Professor Gunhyung Ahn from Dongguk University, Student Heeyeon Heo from Gyeongsang National University

The Gwangju Institute of Science and Technology (GIST) announced on the 22nd that a joint research team led by Dr. Yongryun Cho from the Central Instrumentation Center at GIST and Professor Gunhyung Ahn from Dongguk University has developed a fundamental technology that can significantly improve the performance and durability of zinc-ion batteries by using stainless steel foil coated with graphene.

This technology enables the current collector, a core component of batteries, to become stronger and longer-lasting. Its structure is simple yet delivers excellent performance, making it suitable for mass production and industrial applications. In particular, both the materials and the process are environmentally friendly. Compared to conventional lithium-ion batteries, it is safer and offers superior cost competitiveness.

Graphene is an ultra-thin carbon material with a honeycomb structure. It is lightweight, strong, and has outstanding electrical and thermal conductivity. Stainless steel foil is a very thin and flexible metal sheet made from stainless steel, a rust-resistant metal, and is known for its high strength and durability.

Zinc-ion batteries are attracting significant attention in next-generation large-capacity energy storage systems (ESS) and renewable energy sectors, as they are less expensive than lithium-ion batteries, have a lower risk of explosion, and are easier to secure resources for.

However, these batteries have the drawback of rapid performance degradation during repeated charge and discharge cycles, and their lifespan is shortened due to corrosion caused by aqueous electrolytes.

To address these issues, the research team developed a technique to coat the surface of the current collector?a thin metal plate that conducts electricity?with a thin and uniform layer of graphene. This innovation greatly improved the battery's stability, lifespan, and performance at the same time. In particular, by continuously coating long metal foil with graphene using a 'roll-to-roll' process and then heat-treating it at 400°C, they were able to achieve excellent electrical properties and durability with a simple process.

Roll-to-roll is a process that continuously moves long, thin materials (such as metal foil) and coats their surfaces evenly, much like printing. It excels in mass production and quality uniformity, and is widely used in the manufacturing of batteries and electronic devices.

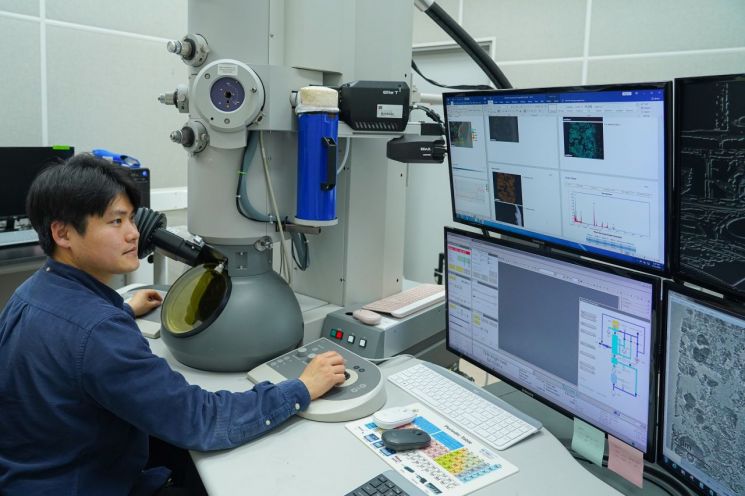

Dr. Yongryun Cho from GIST conducted an experiment using a Transmission Electron Microscope (TEM). Photo by GIST

Dr. Yongryun Cho from GIST conducted an experiment using a Transmission Electron Microscope (TEM). Photo by GIST

Experimental results showed that the battery operated stably even under high energy density (high capacity) conditions, and maintained about 88.7% of its initial capacity after 1,500 charge-discharge cycles, demonstrating excellent cycle life. This is comparable to commercial lithium-ion batteries and is expected to serve as a crucial stepping stone toward the commercialization of zinc-ion batteries.

The research team conducted a detailed atomic-level analysis of the structure and formation process of the graphene coating layer, which formed the basis of this study, using a Transmission Electron Microscope (TEM) at the Central Instrumentation Center of GIST. Through this, they obtained detailed nanoscale composition information such as the thickness, morphology, and layer structure of the graphene film, which played a decisive role in identifying and optimizing the key factors that determine battery performance.

The technology developed by the research team is a core fundamental technology that addresses the structural limitations of zinc-ion batteries. It is expected to serve as an eco-friendly energy solution suitable not only for batteries but also for a variety of applications such as home storage devices, electric vehicles, ESS, and independent power systems (off-grid) in rural or developing regions with insufficient power infrastructure.

Dr. Yongryun Cho from GIST stated, "TEM is an advanced analytical tool that goes beyond simply obtaining images, as it can simultaneously reveal the atomic arrangement and chemical composition inside materials," and added, "By precisely analyzing the structure of graphene-based electrodes, the design of materials and process control for zinc-ion batteries have become even more sophisticated."

Professor Gunhyung Ahn from Dongguk University emphasized, "This technology is an alternative that can overcome the limitations of conventional lithium-ion batteries in the field of energy storage," and added, "As a sustainable energy technology, it will also greatly contribute to reducing energy costs and improving supply chain stability."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)