Korean Researchers Develop Highly Biodegradable Polymer

Promising Solution for Marine Waste Using Existing Facilities

A South Korean research team has developed a polymer material that is more than 92% biodegradable in the ocean within one year, while maintaining strength and flexibility comparable to nylon.

Nylon waste from clothing and fishing nets rarely decomposes in the sea, making it a major cause of global marine environmental pollution. However, with the development of this new material by a domestic research team, significant progress is expected in addressing the issue of marine waste.

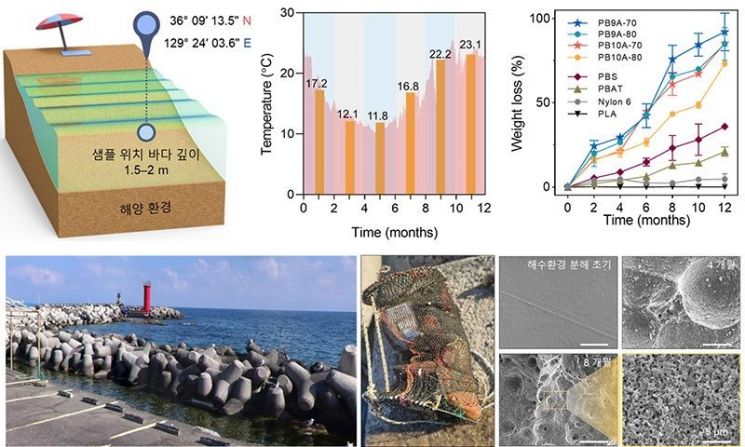

Actual marine degradation test environment and degradation test results. Provided by the KRICT research team

Actual marine degradation test environment and degradation test results. Provided by the KRICT research team

The joint research team, consisting of Dr. Jeon Hyunyeol, Dr. Kim Hyojeong, and Senior Researcher Park Seongbae from the Korea Research Institute of Chemical Technology (KRICT), as well as Professor Oh Dongyeop from Inha University and Professor Park Jaeyoung from Sogang University, announced on April 27 that they have developed a 'polyester-amide (PEA)' polymer.

This material can be mass-produced and recycled, and is suitable for a wide range of applications such as textile fibers, fishing nets, and food packaging. Existing biodegradable plastics decompose well but lack heat resistance and durability, making them difficult to use for clothing or fishing nets.

The joint research team optimized the ratio of ester, which promotes biodegradation, and amide, which provides toughness, to develop the PEA polymer, achieving both high biodegradability and durability.

The team immersed the produced PEA in the sea off the coast of Pohang for one year, resulting in a biodegradation rate of up to 92.1%. This is overwhelmingly higher than existing biodegradable plastics such as polylactide (PLA, 0.1%) and polybutylene succinate (PBS, 35.9%). In actual compost environments in soil, where there are more decomposing microorganisms, the material biodegrades even more completely.

The tensile strength, or the force the material can withstand when pulled, reached over 110 MPa (megapascals), surpassing both nylon 6 and PET. The research team demonstrated that a single strand of PEA fiber could lift a 10 kg object without breaking. When made into fabric, it also withstood ironing at 150°C, demonstrating excellent heat resistance.

The team is currently conducting commercialization assessments of products made from this material through follow-up research, and expects that, after verification of actual industrial application processes, practical use will be possible within two years.

The researchers explained, "The key achievement is overcoming the weaknesses of existing biodegradable plastics while achieving performance comparable to nylon." Lee Youngkuk, President of KRICT, stated, "This technology serves as a turning point that can accelerate the practical industrialization of biodegradable polymers with the properties of conventional engineering plastics, and is expected to contribute to solving the marine waste problem."

This paper was published as a cover article in the March 2025 issue of 'Advanced Materials (IF: 27.4)', a world-renowned journal in the fields of materials and chemistry. Senior Researcher Park Seongbae and Dr. Kwak Hojeong from KRICT were first authors, while Dr. Jeon Hyunyeol and Dr. Kim Hyojeong from KRICT, Professor Oh Dongyeop from Inha University, and Professor Park Jaeyoung from Sogang University served as corresponding authors.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)