Development of a Heat-Resistant Perovskite Solar Cell Enduring 110°C Process Temperatures

Achieving High Stability in Hot and Humid Conditions

22.14% Efficiency for 100 cm² Module Published in Energy & Environmental Science

A perovskite solar cell capable of withstanding 1,000 hours even in steam-cooker-like environments has been developed.

This became possible because the cell can now be coated with a protective film.

A team led by Professor Kim Dongseok at the Graduate School of Carbon Neutrality, UNIST, in collaboration with Professor Lee Taekyung's team at Gyeongsang National University, has developed a heat-resistant perovskite solar cell that can endure the high-temperature process required for applying a protective film.

Research team. (From left) Professor Dongseok Kim, Researcher Jaehwi Lee (co-first author), Dr. Yunseop Shin (co-first author). Provided by UNIST

Research team. (From left) Professor Dongseok Kim, Researcher Jaehwi Lee (co-first author), Dr. Yunseop Shin (co-first author). Provided by UNIST

This cell demonstrated a high initial efficiency of 25.56%, and after operating for 1,000 hours at 85°C and 85% relative humidity, it retained more than 85% of its initial efficiency.

Perovskite solar cells are a next-generation technology that theoretically offers higher efficiency in converting sunlight to electricity and lower costs compared to commercial silicon cells. Although they have already surpassed silicon cells in laboratory settings with efficiencies of up to 27%, one of the barriers to commercialization has been their heat resistance.

Because solar cells are used outdoors for long periods, they must be encapsulated with a film that protects them from moisture and oxygen. Unlike silicon cells, however, perovskite cells cannot withstand the process temperatures that soar up to 110°C.

The research team replaced tBP (4-tert-Butylpyridine) with a substance called Ethylene Carbonate to create a heat-resistant perovskite cell. tBP is an additive used in the hole transport layer of solar cells; while it increases efficiency, it lowers the glass transition temperature of the hole transport layer to below 80°C, making the cell unable to withstand high temperatures. The glass transition refers to the phenomenon where the hole transport layer becomes almost liquid-like.

The cell made with Ethylene Carbonate achieved a power conversion efficiency (PCE) of 25.56%, which is the highest efficiency among cells that do not use tBP. Furthermore, there was almost no efficiency loss even after the encapsulation process for applying the protective film. When the encapsulated cell was tested under international standard conditions of 85°C and 85% relative humidity, it maintained an impressive 21.7% efficiency after 1,000 hours. The glass transition temperature of the hole transport layer also increased to 125°C.

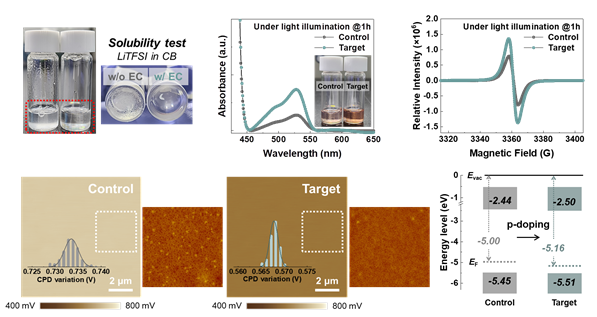

This cell also demonstrated a high efficiency of 22.14% when fabricated as a 100 cm² module. This is because Ethylene Carbonate can dissolve the lithium bismuthide (LiTFSI) dopant as uniformly as tBP. tBP is a substance that helps dissolve LiTFSI in the hole transport layer; when LiTFSI is well-doped, the charge transport performance of the hole transport layer improves, thereby increasing the overall efficiency of the solar cell.

Performance of ethylene carbonate and performance of the hole transport layer made by adding ethylene carbonate.

Performance of ethylene carbonate and performance of the hole transport layer made by adding ethylene carbonate.

Professor Kim Dongseok stated, "Through this research, we have developed a hole transport layer system for solar cells that maintains high efficiency while ensuring stability even in high-temperature and high-humidity environments. This represents a decisive advancement toward the practical application of perovskite solar cells."

This research was led by Dr. Shin Yunseop and graduate students Lee Jaehwi (UNIST), and Lee Dongkyu (Gyeongsang National University) as first authors. The study was supported by the Ministry of Science and ICT, the National Research Foundation of Korea (NRF), and the Ministry of Trade, Industry and Energy.

The results were published on April 7 in Energy & Environmental Science (IF 32.4), the most prestigious journal in the field of eco-friendly energy.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)