New 100,000-seat stadium aims for a 5-year construction period

Dividing the building into 160 blocks for assembly

Goal to realize a 'cost-burden-free' stadium

English Premier League football team Manchester United (Man Utd) has unveiled plans to build a new stadium with a capacity of 100,000 seats. Once completed, it will become the second largest stadium in Europe and the largest in the UK. The British architectural firm 'Foster and Partners' (Partners), which won the project contract, declared that they will complete the stadium construction in just five years?half the usual construction period for stadiums.

Partners has designed large-scale high-tech structures such as London's Wembley Stadium (90,000 seats), the Millau Viaduct in France?the tallest bridge in the world (343m), and Apple's headquarters campus 'Apple Ring' in the United States. How does Partners plan to build a 100,000-seat stadium in just five years?

New 100,000-seat stadium aims for a 5-year construction period

The new 100,000-seat stadium for Manchester United, developed by the global architectural firm Foster and Partners headquartered in the UK. It is a massive structure featuring three 200-meter pillars and a canopy, with the architects aiming to complete construction within five years. Foster and Partners

The new 100,000-seat stadium for Manchester United, developed by the global architectural firm Foster and Partners headquartered in the UK. It is a massive structure featuring three 200-meter pillars and a canopy, with the architects aiming to complete construction within five years. Foster and Partners

Manchester United, a prestigious British football club, already owns a 70,000-seat stadium called 'Old Trafford.' However, since this stadium has stood for 115 years since its opening in 1910, it was determined that mere repairs could no longer sustain the structure, leading to the decision to build a new stadium. Jim Ratcliffe, billionaire co-owner of Man Utd and head of the global chemical company INEOS, stated on the 11th (local time), "We will invest ?2 billion (approximately 3.74 trillion KRW) in the new stadium," and confidently declared, "It will be the world's best football stadium."

The new stadium will have a capacity of 100,000 seats, making it the second largest in Europe after Spain's FC Barcelona's 'Camp Nou' (100,500 seats) and the largest in the UK once completed. However, the most ambitious aspect of this stadium project is the construction period. Norman Foster, the architect leading Partners, declared at a local press conference, "We will open the stadium within five years."

According to Partners' official statement, the typical time required to build a new stadium with a capacity of 100,000 seats is around 10 years (including design and foundational work). For example, Camp Nou is currently undergoing renovation and expansion of its aging infrastructure, and it is expected to take five years from 2022 to 2026 just to expand the stadium from 100,000 to 100,500 seats.

Dividing the building into 160 blocks for assembly

The architect plans to actively utilize the prefab construction method by dividing the stadium into 160 blocks, designing each block separately, and then assembling them at the construction site. Manchester United official X

The architect plans to actively utilize the prefab construction method by dividing the stadium into 160 blocks, designing each block separately, and then assembling them at the construction site. Manchester United official X

Architect Norman has decided to fully utilize 'prefab' technology for the construction of the new Man Utd stadium. Prefab is a construction method where parts of the building are manufactured in factories like components and then transported to the site to be assembled into a completed structure. This method significantly shortens the construction period compared to transporting construction materials to the site and building the structure piece by piece.

The new Man Utd stadium was designed from the outset with prefab in mind. The entire stadium is divided into 160 'blocks' for design purposes. Each block is manufactured at factories spread across the UK, and the completed blocks are transported by cargo ships to the actual construction site.

This plan is also made possible by the unique environment of Manchester, the city where the Man Utd stadium will be built. Manchester, traversed by the River Irwell, has operated the Manchester Ship Canal since the Industrial Revolution. Since the Man Utd stadium will be built near the waterfront where the canal passes, transporting the stadium blocks is convenient.

Goal to realize a 'cost-burden-free' stadium

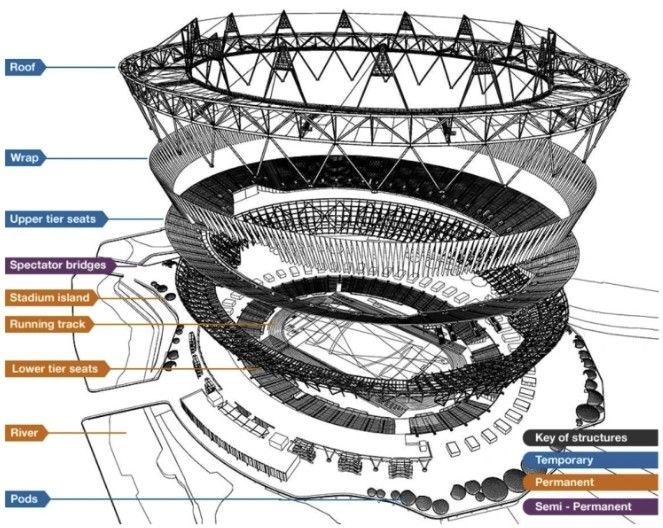

Using prefab technology for constructing a large-scale stadium is also considered advantageous in terms of cost and environmental impact. The 'London Stadium,' built for the 2012 London Olympics, also applied prefab technology to reduce maintenance costs after opening.

The stadium was originally designed to accommodate 25,000 seats, but by stacking seats and roofs made with prefab methods layer by layer, it can be expanded to a maximum capacity of 80,000 seats. The upper tiers and roof structures of the stadium can be dismantled by detaching fixed cables, and the dismantled parts can be transported to other stadiums for reuse. Thanks to prefab technology, the London Stadium has been able to minimize maintenance costs and continue sustainable operations after the Olympics.

Structural diagram of the 2012 London Olympic Stadium. It was the first stadium to apply prefab technology to the upper seats and roof, allowing the upper structure to be dismantled after the Olympics to save maintenance costs. Populous

Structural diagram of the 2012 London Olympic Stadium. It was the first stadium to apply prefab technology to the upper seats and roof, allowing the upper structure to be dismantled after the Olympics to save maintenance costs. Populous

The Manchester City government, which has expressed strong support for Man Utd's 'prefabricated stadium' plan, also expressed its ambition to make the new Man Utd stadium an even greater prefab stadium than the London Stadium.

Andy Burnham, Mayor of Manchester, stated in a press release on the 11th, "If this (stadium construction) is done properly, I believe it can be even more positive than the 2012 London Olympic Stadium," emphasizing, "This vision is faithful to the football club's tradition and sets a new global standard for stadiums that are affordable and accessible to everyone."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.