Chung Mong-koo's Commitment to Quality Management

Immediate Reflection of U.S. IQS Consumer Feedback in New Models

Laying the Foundation for Quality Management and Expanding U.S. Exports

Generational Continuity in Quality Management... Ranked No. 1 Globally in U.S. IIHS Safety Ratings

"Make the free repair period in the U.S. over 10 years. If you make a car that doesn't break down for 10 years, isn't that enough?" (Chung Mong-koo, Honorary Chairman of Hyundai Motor Group)

In 1999, Hyundai Motor Company introduced a groundbreaking policy in the United States. It offered a '10-year/100,000-mile' free engine warranty repair policy. Compared to the average warranty period of competitors at the time, which was '2 years/24,000 miles,' this was a tremendous gamble. This critical decision, which could have resulted in astronomical warranty repair costs, was something only the owner could decide. It was both a declaration of war on the U.S. market and a way to instill a sense of urgency about quality among Hyundai’s internal members. With such a high goal, they bet their lives on quality. Or rather, they had to. The mindset of setting a goal first and then producing results accordingly was something he learned from observing his father.

A few months before announcing this policy, Honorary Chairman Chung was deeply shocked during a business trip to the U.S. Hyundai cars, painstakingly manufactured and exported from Korea, were being treated like outcasts in America. In fact, a U.S. TV talk show even satirized the U.S. government's flawed policies by comparing them to Hyundai's purchasing policies. Negative perceptions about quality spread, and Hyundai became a subject of ridicule in the U.S. that year. Sales in the U.S. market dropped to a historic low of about 80,000 units. To overcome this, Honorary Chairman Chung took a bold gamble by introducing the '10-year/100,000-mile free engine warranty.' Researcher Choi Bu-sik of POSCO Research Institute cited Hyundai’s case in his 2006 paper, "Consumer Perception of Warranty Period as a Quality Signal," analyzing that "when complete quality information is unavailable, consumers are likely to make decisions based on the warranty period offered," and "consumers understand that warranties are costly, so a long warranty can be seen as confidence in quality."

Chung Mong-koo, Honorary Chairman of Hyundai Motor Group, is inspecting the local production line during his visit to Kia's Slovakia plant in 2016. Photo by Hyundai Motor Group

Chung Mong-koo, Honorary Chairman of Hyundai Motor Group, is inspecting the local production line during his visit to Kia's Slovakia plant in 2016. Photo by Hyundai Motor Group

Even today, the epithets that follow Honorary Chairman Chung are 'tenacity' and 'quality.' Among these, quality was the top management value he prioritized until he stepped down from frontline management in 2017. Most photos of him in the media since the 2000s show him wearing work clothes and a safety helmet, carefully inspecting cars. An executive who attended quality meetings chaired by Honorary Chairman Chung recalled, "His on-site management was never for show," adding, "He always surprised us by pinpointing important issues from both expert and consumer perspectives."

'MK's Cars' Carnival and Grace... The Beginning of Quality Management

Right after acquiring Kia in 1998, the first order Honorary Chairman Chung gave was to bring the Kia minivan Carnival to his residence in Hannam-dong. He parked the Carnival in his front yard and examined it day and night. At the same time, he requested Kia President Kim Su-jung to secure a space for quality meetings. President Kim prepared about 100 pyeong (approx. 3,300 sq ft) in the basement of Kia’s Yeouido building, creating a meeting room on one side and a new car display area for quality inspection on the other. A month later, the first Kia quality meeting was held there, focusing on improving the Carnival's marketability. Upon entering the meeting room, Honorary Chairman Chung circled various parts of the Carnival’s body with chalk. Each time white chalk dust fell, the executives’ hearts sank. "Fix all the parts I marked here," he said, pointing out the issues he had frequently observed. Engineers immediately corrected and reported on his comments. The Carnival, which received the chairman’s full attention, was relaunched as a new model in 2001. In its first year, it recorded the highest domestic sales ever (74,218 units) and surpassed 100,000 units in global sales as exports increased.

Another vehicle symbolizing Honorary Chairman Chung’s quality management is Hyundai’s small van, Grace. This also happened shortly after he assumed the chairmanship in 1999. He visited the Ulsan plant to inspect Grace’s quality. In front of all employees, he slammed the sliding door open and shut repeatedly. After more than twenty loud bangs, the sliding door eventually came off its rail. Seeing this, Honorary Chairman Chung coldly ordered, "Make it again from the beginning." The Grace production process, which had undergone years of R&D and already received orders, was completely halted. This anecdote is regarded as the first example demonstrating his commitment to quality management to employees. It was to instill the awareness that if a car is not made properly from the start, enormous costs will be incurred, and mistakes must be corrected without fail.

Hyundai Motor Group Recognized in U.S. Market Research

"The biggest difference between Hyundai and Toyota is that Hyundai accepts J.D. Power’s advice every year."

This is the statement of Cho Sung-hwan, Chairman of the International Organization for Standardization (ISO) and former President of Hyundai Mobis, who worked at Hyundai Motor Group for nearly 30 years. He joined Hyundai as a researcher in 1994 and served as head of Hyundai’s U.S. Technology Research Center, deputy head of R&D headquarters, and CEO (President) of Hyundai Mobis. As a 'Hyundai researcher' to the core, he analyzed Hyundai Motor Group’s quality management secret as follows. Cho explained, "Competitors do not immediately reflect the results of the Initial Quality Study (IQS) in the same year it is released," adding, "In contrast, Hyundai reflects consumer feedback from IQS every year during model year changes."

Typically, new car launches include full changes (complete redesigns of design, engine, and convenience features), partial changes (facelifts that only alter exterior design), and annual updates (minor specification updates each year). Competitors usually incorporate IQS evaluations into partial changes every 2-3 years or only consider doing so. However, Hyundai analyzes consumer evaluations annually and actively reflects them in yearly updates. Cho emphasized, "Hyundai constantly questions, 'What does this mean? Why did they answer this way? Why did they say this is inconvenient?' Even though it requires investment of costs and human resources, they always strive for continuous improvement."

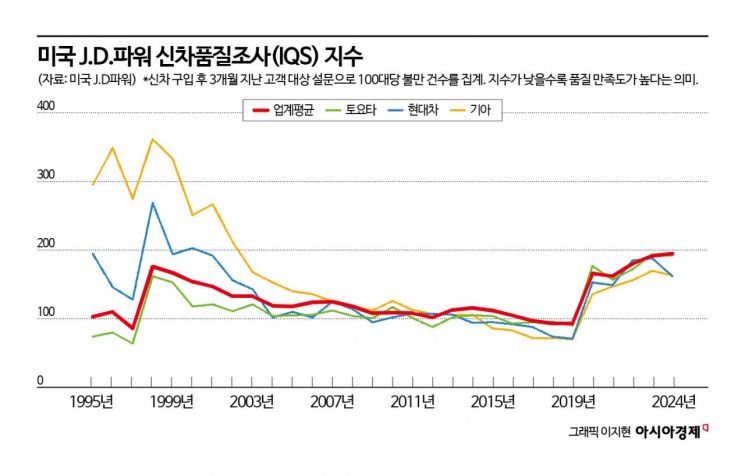

The IQS conducted by U.S. market research firm J.D. Power is the world’s most prestigious automotive quality evaluation, started in 1987. It surveys new car quality based on consumer experiences within three months of purchase, counting and weighting complaints per 100 vehicles and converting them into scores. A lower score means higher quality satisfaction. Comparing IQS scores of Hyundai, Kia, and Toyota over the past 30 years from 1995 to 2024, Hyundai could not catch up with Toyota until the early 2000s. However, five years after Honorary Chairman Chung declared the quality management policy, Hyundai surpassed Toyota for the first time in 2004. This was three years ahead of Hyundai’s internal target. At that time, U.S. media expressed astonishment with the headline "Man Bites Dog." Since then, the scores of the two companies fluctuated until Hyundai’s superiority was established after 2014. From 2014 to 2024, Hyundai consistently scored lower (better) than Toyota in IQS except for 2022.

Kia’s transformation was even more dramatic. Just before being acquired by Hyundai in 1998, Kia’s IQS was at its worst in 30 years, reaching 362. But under an active quality management policy, Kia’s IQS sharply declined to around 100 by 2009. Based on overall brand rankings, Kia ranked first for two consecutive years in 2016 and 2017 and has maintained a top position since. In the 2024 IQS survey, Hyundai and Kia ranked 3rd and 4th respectively. When averaging scores across 15 automotive groups, Hyundai Motor Group recorded the lowest average score of 164, securing the overall first place.

Chung Mong-koo, Honorary Chairman of Hyundai Motor Group, is inspecting the production site at Hyundai Motor's Alabama plant in the United States in 2014. Photo by Hyundai Motor Group

Chung Mong-koo, Honorary Chairman of Hyundai Motor Group, is inspecting the production site at Hyundai Motor's Alabama plant in the United States in 2014. Photo by Hyundai Motor Group

‘Pumsaeng Pumsa’?Honorary Chairman Chung Mong-koo’s Management Know-how

When guests visit from overseas, Honorary Chairman Chung always shows them one place: the Quality Situation Room located on the first floor of Hyundai Motor’s Yangjae building. On the right wall at the entrance hangs a large frame measuring 2 meters by 2 meters. Titled "J.D. Power’s Advice," it summarizes five quality criticisms given by a senior J.D. Power official during a 2001 visit to Hyundai. The specific points are: ▲Customer voices are not properly reflected in product planning, design, and production stages ▲Chronic quality problems repeat even when models change ▲Countermeasures for problem resolution are incomplete ▲The number of problems per vehicle is 2-3 times higher than average ▲Quality control of suppliers is insufficient.

Honorary Chairman Chung addressed each of these criticisms one by one. First, when moving the headquarters from Gyedong to Yangjae in 2001, he ordered the creation of a quality meeting, securing, and situation room on the most visible first floor. He frequently chaired quality meetings there and checked specific issues. He also converted the Quality Situation Room into a 24-hour operation system to promptly handle complaints from overseas customers. Complaints were compiled into reports and uploaded to a computer system accessible to all employees. The chairman personally reviewed these reports to monitor progress and even reprimanded executives who did not read them. He introduced a quality pass system that prevents production from moving to the next stage without securing quality.

In 2002, he launched the Quality Management Headquarters directly under the chairman and invested 100 billion KRW to install engine inspection systems at production plants worldwide. To strengthen supplier competitiveness, he introduced the 'Quality 5-Star System,' which scores suppliers based on management systems, defect rates of supplied parts, number of claims, and claim responsibility rates. As the chairman put his life on quality, employees naturally prioritized quality as their top concern. This led to product improvements followed by sales expansion after some time lag. Hyundai’s U.S. exports, which had fallen to about 80,000 units in 1999, surged more than tenfold to 850,000 units in 2004, laying the foundation for Hyundai Motor Group’s global 5th place ranking in 2009. Professor Hyun Young-seok of Hannam University’s Business Administration Department evaluated, "The CEO’s immersion and direct involvement in quality is crucial for focusing employees’ attention and company resources to solve problems and accelerate innovation."

The Current Status of Hyundai and Kia’s Quality Management in 2025

Hyundai Motor Group’s quality management continues across generations. As of 2025, Brian Latouf, Global Chief Safety & Quality Officer (GCSQO, President) overseeing Hyundai and Kia’s quality, said, "Chairman Chung is a person with tremendous passion for safety and quality," adding, "Even recently, I have met him countless times to discuss challenges related to safety and quality. He pursued uncompromising perfection and always emphasized putting the customer at the center."

Since Latouf joined Hyundai Motor Group, a new safety and quality monitoring system has been introduced: the 'Speak Up for Safety' program. If general employees or overseas dealers have safety or quality concerns during vehicle testing, they can report directly to President Latouf through this program. Hyundai and Kia’s efforts to secure quality are also evident in safety evaluations. This year, Hyundai Motor Group announced that 12 models were selected for top safety ratings (TSP and TSP+) in crash tests conducted by the U.S. Insurance Institute for Highway Safety (IIHS). This achievement ranks first among global automotive groups.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)