Development of Eco-Friendly Dry Electrode Manufacturing Technology

On the 6th, Chung-Ang University announced that Professor Nam In-ho's chemical engineering research team has developed a dry process technology for lithium-ion batteries.

Professor Nam In-ho's Research Team

Professor Nam In-ho's Research Team(from left: Ji-hyun Kang, PhD candidate; Ho-jong Eom, PhD candidate; Seo-hyun Jang, PhD candidate; Professor Nam In-ho)

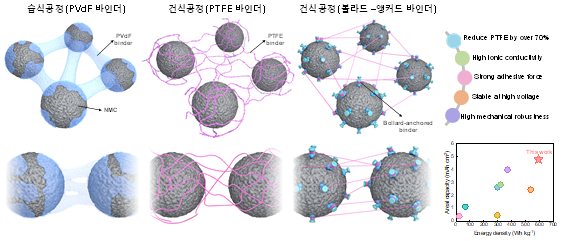

The research team developed a dry electrode process system that manufactures electrodes without solvents, departing from the conventional wet process. This demonstrated the possibility of eco-friendly battery manufacturing while maintaining high energy density.

As the electric vehicle and energy storage system (ESS) markets expand, the development of thick electrodes with high density is becoming essential. In particular, dry process-based thick electrode manufacturing technology is gaining attention as an alternative to the existing wet process.

The dry process manufactures electrodes without using toxic solvents. Since no drying process is required, recovery efficiency can be maximized. It also offers advantages such as shortening the manufacturing process, improving production speed and efficiency, and reducing energy consumption by up to 30%.

The research team developed a "Bollard-Anchored" binder system inspired by the bollard structure used to moor ships at ports. This method first attaches the formed binder (PC) to the cathode material, reducing PTFE usage by more than 70% while maintaining mechanical stability.

The binder system developed by the research team improved ionic conductivity and adhesion, showing more than 1.7 times better performance compared to conventional PTFE even under high-rate charge and discharge. This is expected to be widely utilized in next-generation electric vehicles and energy storage systems that require high-density and high-performance batteries.

The study was co-first authored by doctoral candidates Kang Ji-hyun, Eom Ho-jong, and Jang Seo-hyun. Additionally, Hyundai Motor Company's battery process technology development team and Professor Han Jung-woo's research team at Seoul National University participated in the research. The results were published in the prestigious international journal Advanced Materials.

Professor Nam In-ho stated, "This research presents an innovative electrode manufacturing technology that simultaneously satisfies eco-friendliness and high performance, establishing a new paradigm for dry electrode processes." He added, "It has great potential for commercialization in various industrial fields such as electric vehicles, large-scale ESS, and aerospace batteries."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)