Development of Highly Crystalline Organic Anode Material for Lithium-Ion Batteries by UNIST and KIST

Outstanding Electrochemical Performance Thanks to High Crystallinity... Published in ACS Nano

An organic anode material that can enhance the capacity and price competitiveness, which were limitations of high-speed charging battery materials, has been developed.

Professor Seok-Joo Kang's team from the Department of Energy and Chemical Engineering at UNIST and Dr. Seok-Hoon Ahn's team from the Korea Institute of Science and Technology (KIST) have developed a highly crystalline organic anode material for lithium-ion batteries.

In winter, the charging speed of electric vehicle batteries slows down because the diffusion rate of lithium ions within the battery anode decreases.

For this reason, electric buses, where fast charging is important, use batteries with LTO materials instead of graphite for the anode. However, LTO has about half the capacity of graphite and is more expensive.

The research team developed a highly crystalline organic anode material called ‘Cl-cHBC’ with a maximum capacity 1.5 times greater than that of LTO. Organic materials have advantages such as being inexpensive and lightweight, but their crystallinity is low, so high-temperature post-treatment is required to improve crystallinity.

The team synthesized an organic anode material exhibiting high crystallinity even at low temperatures through an anti-solvent crystallization process. Anti-solvent crystallization is a process method that adds a solvent with low solubility to crystallize the solute.

The developed highly crystalline anode material has a fast lithium-ion diffusion rate and high electrical conductivity. As the crystallinity, which is the regularity of the microstructure, increases, the paths for ion and electron movement become straighter. Thanks to this, fast charging is possible, and the output has improved. Higher crystallinity also leads to longer lifespan.

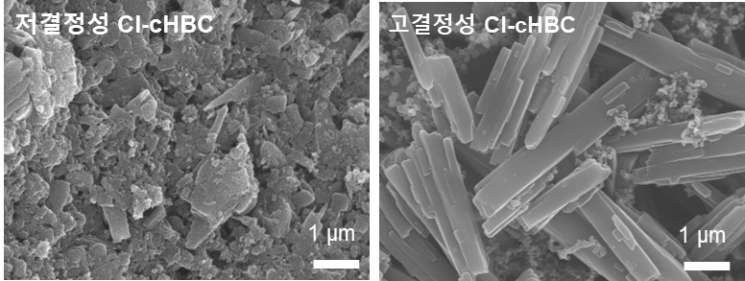

Comparison of crystallinity of organic cathode materials by manufacturing method. (Electron microscopy analysis to explain the difference in crystallinity of Cl-cHBC fabricated using anti-solvent crystallization technology)

Comparison of crystallinity of organic cathode materials by manufacturing method. (Electron microscopy analysis to explain the difference in crystallinity of Cl-cHBC fabricated using anti-solvent crystallization technology)

When paired with various cathode materials to produce batteries, stable performance was secured. Especially when combined with LFP cathode material, it showed a high discharge voltage (3.0V). This performance is about 67% better than when using LTO anode material. Batteries using LFP cathode materials, mainly used in imported electric vehicles, have excellent price competitiveness but suffer from lower discharge voltage, i.e., output.

The joint research team explained, “The developed material can be synthesized at low temperatures without high-temperature post-treatment processes, which will additionally secure price competitiveness upon commercialization,” and added, “Due to its lightweight and high output characteristics, applications are expected not only in electric vehicles but also in fields such as drones.”

This research involved Ji-Ho Ha, a researcher from the Department of Energy and Chemical Engineering at UNIST, as the first author.

Hajiho, UNIST Researcher (First Author).

Hajiho, UNIST Researcher (First Author).

The research results were published on the 21st of last month in ACS Nano, a world-renowned journal in the field of energy materials. The research was conducted with support from the National Research Foundation of Korea (NRF), Korea Institute of Science and Technology (KIST), and the Center for Materials Commercialization and Promotion (COMPA).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)