Optimization Work Underway to Achieve 94% Yield for DX-M1

DeepX, a domestic on-device artificial intelligence (AI) semiconductor design company, announced on the 25th that it will receive its first mass production wafer through Samsung Electronics' 5nm (nanometer, one billionth of a meter) process by the end of this year since its establishment. Mass production wafers are important indicators for checking product stability and efficiency before large-scale production.

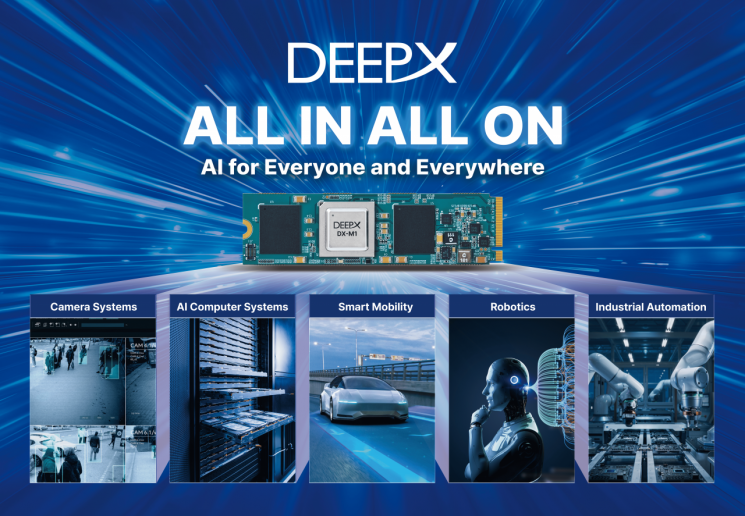

DeepX is currently optimizing mass production of its first-generation AI semiconductor 'DX-M1' with a target yield of 91-94%. Through this, the company plans to secure high price competitiveness for its products. DeepX stated, "As a newly established fabless company, we expect an unprecedented achievement of dominating the global semiconductor distribution network simultaneously with our first mass production."

Kim Nok-won, CEO of DeepX, said in an interview with Asia Economy last month, "We will release the first mass production wafer of DX-M1 by the end of December this year and launch the final product in January next year." He added, "We received a prototype from Samsung Foundry in June, which sufficiently proved mass production feasibility in terms of performance and power consumption." Prior to this mass production, DeepX conducted preliminary mass production tests and reliability verification based on sample chips produced through Multi-Project Wafer (MPW), achieving a yield of 87%. MPW refers to a method of manufacturing different types of chips on a single wafer.

On June 11, at the headquarters of Taiwanese electronic device manufacturer Inventec, Kim Nok-won, CEO of DeepX (left), and Jack Chai, President of Inventec, signed a 'Memorandum of Understanding (MOU) for AI Semiconductor Business' and took a commemorative photo. Provided by DeepX

On June 11, at the headquarters of Taiwanese electronic device manufacturer Inventec, Kim Nok-won, CEO of DeepX (left), and Jack Chai, President of Inventec, signed a 'Memorandum of Understanding (MOU) for AI Semiconductor Business' and took a commemorative photo. Provided by DeepX

DeepX plans to maximize product stability by applying the high-reliability System-Level Test (SLT) to all products, even if manufacturing costs increase. SLT is a test that verifies the overall functionality of a semiconductor when connected to actual machines or systems to ensure proper operation. Although this method is generally used only for products requiring high reliability, such as automobiles, DeepX decided to apply this test to all products, focusing on the fact that AI semiconductors are mainly used in unmanned machines and automated equipment. While this incurs higher costs, it maximizes semiconductor safety and quality.

CEO Kim said, "The DX-M1 product possesses global top-level technology that satisfies the three core semiconductor values: price competitiveness, computational performance, and power consumption and heat control, and we are now starting mass production." He added, "This year's multiple awards, attraction of global customers and partners, and distribution network establishment are results recognizing the excellence of DeepX's core technology." DeepX has filed over 300 patents related to AI semiconductors worldwide, securing the largest number of core patents among global AI semiconductor companies. This year, it won three CES Innovation Awards and was selected as an AI semiconductor company for two consecutive years by the global electronics media EETimes, recognizing its technological prowess.

Before product launch, DeepX has collaborated with global companies on developing application products equipped with 'DX-M1.' These include ▲physical security with China's Hikvision and the U.S.'s Honeywell ▲workstation and server sectors with the U.S.'s Dell, U.S.'s Supermicro, China's Inspur, China's Lenovo, U.S.'s HP, Taiwan's Ktus, and Taiwan's AIC ▲retail with the U.S.'s Walmart and Amazon ▲industrial PC with Taiwanese companies such as Advantech, ASUS, Inventec, IEI, and DFI ▲robotics with China's Hikrobot and Germany's Neura Robotics.

CEO Kim said, "We have gained extensive experience in customer response by resolving various bugs and additional technical requirements that arose during interoperability testing with global customers' application systems in over 20 fields and the mass production development process, as well as identifying issues before official mass production."

DeepX has received product evaluation requests from over 200 global companies in Greater China, the U.S., and Europe, and has supplied engineering samples to the global market. Domestically, it is collaborating with more than 10 large companies related to physical security, factory automation, and robotics, discussing or developing application products equipped with DeepX products. Additionally, it has received turnkey project collaboration proposals from multiple global companies for new AI semiconductor development and is currently coordinating requirements between both parties.

DeepX is also preparing its product distribution in advance. Last year, it signed a distribution contract with Taiwan's CoAsia Electric, and this year with Korea's Daewon CTS. It is also discussing cooperation with Arrow, the No.1 electronic component distributor in North America and Europe; WPG, a leading semiconductor distributor in Asia; WT, a Taiwanese electronic component distributor; and DigiKey, the No.1 online semiconductor distributor in the U.S.

CEO Kim said, "We will continue to supply all application systems existing in the market, continuously improve usability, portability, and software technology quality, and elevate DeepX products to the status of premium brands."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)