Incheon Factory Fire: Sandwich Panels Acted as Fire Starters

Manufacturing Standards Exist but Defective Products Circulate On-Site

Last weekend, a large fire broke out at an industrial machinery manufacturing factory in Incheon, destroying 36 businesses. The fire department believes that sandwich panels acted as kindling. There are calls to strengthen management standards for sandwich panels, which have been a recurring issue in major fires.

According to the building materials industry on the 23rd, sandwich panels that have been deemed unsuitable are still being distributed at construction sites. Sandwich panels have long been identified as a cause that exacerbates fire disasters. As a result, in 2022, regulations were strengthened to require the insulation materials used in sandwich panels to be made of semi-noncombustible or higher materials that are relatively fire-resistant.

On the morning of the 21st, a building in the factory area of Wanggil-dong, Seo-gu, Incheon, was burned by fire. The fire that occurred the previous day damaged 76 buildings belonging to 36 companies. (Photo by Yonhap News)

On the morning of the 21st, a building in the factory area of Wanggil-dong, Seo-gu, Incheon, was burned by fire. The fire that occurred the previous day damaged 76 buildings belonging to 36 companies. (Photo by Yonhap News)

However, sandwich panels made from fire-vulnerable materials and deemed unsuitable are still being distributed on site. According to data from the Citizens' Coalition for Economic Justice, when the government collected products from 10 sandwich panel companies in November last year and conducted flame retardancy tests, all but one of the 10 companies received unsuitable ratings.

Additionally, according to the Ministry of Land, Infrastructure and Transport's 2023 and 2024 "Building Safety Monitoring Plans and Results," inspections were conducted on 196 sandwich panels in 2023, resulting in 19 unsuitable ratings, an unsuitability rate of about 10%.

In the case of sandwich panels, due to the difficulty for individual companies to obtain quality certification, a standard model system is operated. The standard model allows manufacturing and sales without individual quality tests and certification reviews, based only on representative tests.

Regarding this, an industry insider explained, "There are cases where sandwich panels that meet the standards are certified through representative tests, but products that do not meet the standards are distributed on site," adding, "There are absurd situations where products are certified only to pass the test, but are difficult to mass-produce or apply on site."

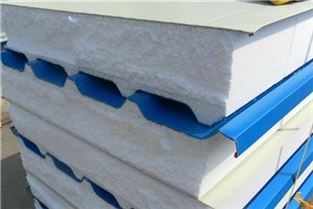

Appearance of sandwich panel.

Appearance of sandwich panel.

The problem lies in cost and manpower. It is impossible to inspect all delivery sites nationwide, and small and medium-sized companies producing sandwich panels manufacture substandard products to reduce costs. At construction sites, a vicious cycle repeats where cheap sandwich panels that do not meet standards are sought.

Civil society organizations have called for revisions to the sandwich panel standard model system. The Citizens' Coalition for Economic Justice believes that if quality control had been strictly enforced, companies producing unsuitable materials would have been eliminated from the market, preventing small fires from escalating into large-scale fires.

There are also calls for tougher penalties. Ye In-hwan, director of the Fire Safety Research Institute at the Korea Institute of Civil Engineering and Building Technology, said, "Since the problem is the distribution of defective products during the distribution process, rather than strengthening current regulations, measures are needed to ensure that existing regulations are properly followed." He added, "Penalties such as recalls should be imposed when defective products are detected."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)