Conducted on the 15th at Sampyo Industrial Technology Research Institute

Purpose is to verify if consistent quality can be ensured

Sampyo Group announced on the 22nd that it has verified the safety of its cold-resistant concrete, ‘Bluecon Winter,’ through performance testing.

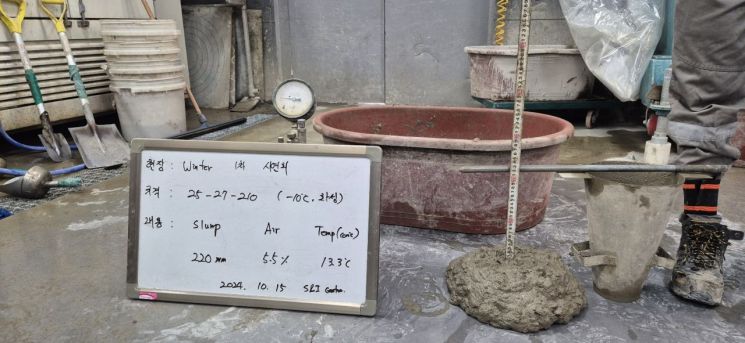

On the 15th, a performance verification test for the application of 'Bluecon Winter' was conducted at Sampyo Industrial Technology Research Institute located in Hwaseong, Gyeonggi.

On the 15th, a performance verification test for the application of 'Bluecon Winter' was conducted at Sampyo Industrial Technology Research Institute located in Hwaseong, Gyeonggi. [Photo by Sampyo Group]

Sampyo Industrial, a subsidiary of Sampyo Group, conducted a performance verification test for the application of Bluecon Winter on the 15th at its technology research center located in Hwaseong, Gyeonggi Province. About 50 stakeholders, including construction site supervisors and quality managers, attended the test. The purpose of this test was to confirm whether Bluecon Winter can secure uniform quality.

Bluecon Winter is a winter-specific concrete that can be poured even at minus 10 degrees Celsius. It is characterized by achieving a compressive strength of 5 megapascals (MPa) within 48 hours of pouring with only surface vinyl curing, without the need for separate curing or heat curing. One MPa is the strength that can withstand a load of 10 kg per 1 cm² of concrete.

This time, tests on the properties of unset concrete were conducted, including slump (a measure of concrete fluidity), air content (the amount of air contained in the concrete), and temperature measurement. Afterward, concrete was poured into members similar to actual structures, and compressive strength was measured 48 hours later. Additionally, compressive strength tests will be conducted at 7 and 28 days for comparative analysis.

The test replicated the environmental conditions of a ready-mix concrete plant during winter. The simulated members were placed in a large chamber (equipment that controls and maintains temperature in a sealed space for testing at specific temperatures) and cured at minus 10 degrees Celsius for 48 hours. Aggregates actually used at various plants, including Hwaseong, Anyang, Gwangju, Anseong, Dongseoul, Namyangju, and Songdo, were directly used in the mixing experiments, enhancing the reliability of the product.

Park Min-yong, Executive Director of Sampyo Industrial, said, “We are dedicating all our efforts to creating a foundation for the building materials industry to take a step forward through continuous core technology development and quality improvement.” He added, “Through future research and development, we plan to commercialize no-curing products that do not require surface vinyl curing and cold-resistant concrete that can be used at even lower temperatures.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)