Year-End Overspending Expected, Investment Execution Exceeding Annual Net Profit

The Korea Cement Association announced on the 12th that out of this year's total facility investment plan of 607.6 billion KRW, 589.2 billion KRW has already been executed, achieving a rate of 97%. If this trend continues, it is expected that the investment amount will exceed the original plan by the end of the year.

Despite the double hardships of a sharp decline in cement shipments and a surge in inventory due to the prolonged downturn in the construction market, the domestic cement industry is accelerating facility investments to reduce the environmental impact generated during product manufacturing.

This reflects the judgment that securing mid- to long-term growth engines is more urgent than tightening belts, in order to proactively respond to increasingly stringent environmental standards and to achieve early carbon neutrality for the global issue of greenhouse gas reduction.

As the scale of investment, which has been rapidly increasing year by year, requires the entire expected net profit for this year, concerns are growing about how to cope with the anticipated electricity rate hikes and sharp rises in major raw material prices in the future.

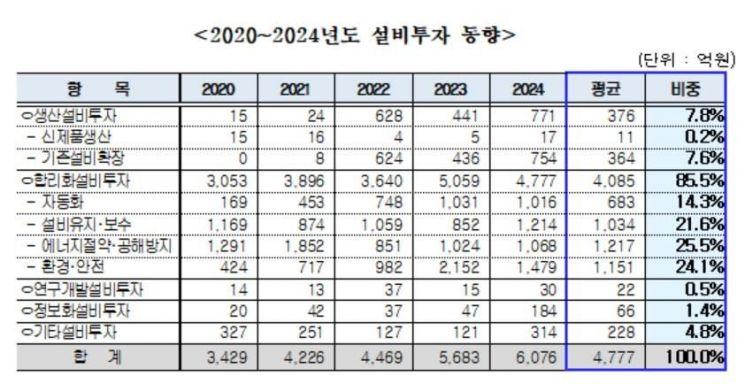

The cement industry has rapidly expanded its facility investment funds over the past five years. The investment scale, which was 342.9 billion KRW in 2020, is planned to nearly double this year to 607.6 billion KRW. Investments to reduce environmental impact account for about 80% of the total investment amount, excluding the cost of installing Selective Catalytic Reduction (SCR). If SCR installation begins in earnest in the future, the investment scale is expected to surge.

The early execution policy of facility investment this year is due to the need to advance investments in pollution reduction facilities in preparation for increasingly stringent environmental standards and the inevitable construction and expansion of related facilities to stably expand the use of circular resources necessary to achieve carbon neutrality.

However, there are many uneasy views within the cement industry recently about whether future facility investment execution will proceed smoothly. Due to the characteristics of the capital-intensive industry, securing funds is the key to stable facility investment, but physical indicators are worsening due to a sharp decline in shipments (12.3%↓) and a surge in inventory (15.6%↑) in the first half of this year.

Moreover, considering the scheduled electricity rate hikes in the second half of the year, the situation is extremely challenging. In particular, electricity costs, along with bituminous coal procurement costs, account for the highest proportion of cement manufacturing costs. Although bituminous coal procurement costs stabilized somewhat last year, the electricity rate hike offset this, and the dominant analysis is that no windfall gains were realized.

A Korea Cement Association official said, "Although member companies recorded a net profit of 319.4 billion KRW in the first half, considering the facility investment plans, the expected net profit for this year will be fully invested in facility investments to reduce environmental impact," adding, "The first half results, which reflect a temporary base effect, are merely a case of 'external splendor, internal poverty'."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)