Development of New Carbon Material Electrode Additive

Enhanced Durability of Polymer Electrolyte Fuel Cells

Professor Seo Minho from the Department of Nano Convergence Engineering at Pukyong National University, Dr. Choi Seungmok from the Korea Institute of Materials Science, and Professor Um Kwangseok's research team from Gwangju Institute of Science and Technology (GIST) have successfully enhanced the durability of commercial-level polymer electrolyte fuel cell systems by utilizing a newly developed carbon material as an additive in the electrode manufacturing process for the first time in the world.

Research team (from left: Song Jin, PhD student; Junhwa Kwon, PhD; Seungmok Choi, PhD; Kwangseop Eom, Professor; Minho Seo, Professor).

Research team (from left: Song Jin, PhD student; Junhwa Kwon, PhD; Seungmok Choi, PhD; Kwangseop Eom, Professor; Minho Seo, Professor).

The polymer electrolyte fuel cell, which is gaining attention as an eco-friendly and highly efficient battery, generates electricity by using hydrogen as fuel through a hydrogen oxidation reaction, with water as the only byproduct.

However, in existing polymer electrolyte fuel cell systems, a high voltage of over 1.4V occurs during the start-up on/off process, accelerating carbon corrosion in the catalyst layer. This leads to catalyst layer collapse and water flooding inside the electrode during the oxygen reduction reaction, resulting in a rapid decrease in durability.

Professor Seo Minho's research team effectively improved the durability of fuel cells by using a new carbon material with high corrosion resistance as an additive in the electrode, addressing the issue of durability degradation caused by carbon corrosion.

The fluorine-doped graphene nanoribbon and carbon nanotube composite (F-GNR@CNT) used in this study was developed to overcome the carbon corrosion vulnerability of conventional graphene nanoribbon oxides.

Traditional graphene nanoribbon oxides become rich in oxygen functional groups due to strong chemical oxidation during synthesis, making them highly susceptible to electrochemical carbon corrosion during fuel cell operation because of many defects and instability at boundary regions. Professor Seo Minho's team synthesized a carbon nanotube composite with high internal corrosion resistance by controlling the oxidation degree and formed stable carbon-fluorine bonds through a heat treatment process for fluorine doping.

Professor Seo Minho's team, together with Dr. Choi Seungmok from the Korea Institute of Materials Science and Dr. Choi Youngwoo's team from the Korea Institute of Energy Research, developed an electrode optimization process technology by adding a minute amount of the F-GNR@CNT composite and manufactured the electrode.

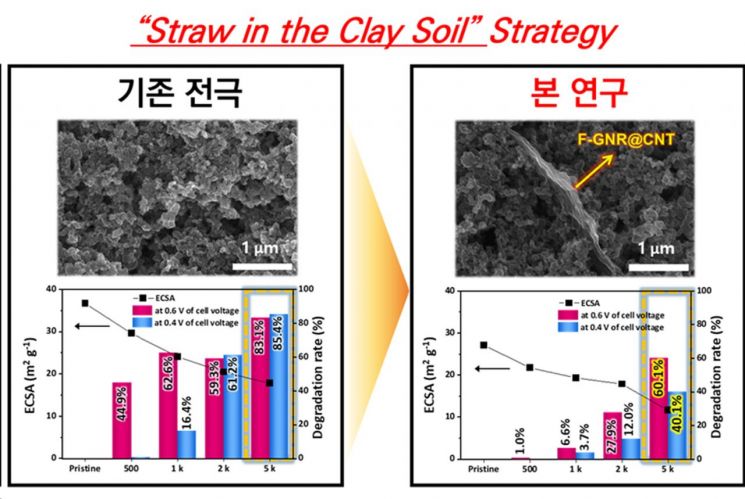

In collaboration with Professor Um Kwangseop's team at GIST, the electrochemical carbon corrosion accelerated durability of this electrode was evaluated. While the degradation rate in the mass transport region of conventional catalyst layer electrodes was about 85%, the electrode with the new carbon material showed a degradation rate of about 40%, confirming very high resistance to electrochemical carbon corrosion.

Professor Seo Minho's team also identified the theoretical mechanism for increased carbon corrosion resistance through density functional theory (DFT). By modeling the graphene nanoribbon and carbon nanotube structures and calculating the adsorption energies with water and oxygen atoms, which are factors in carbon corrosion, depending on the presence of fluorine doping, they showed that the fluorine-doped graphene nanoribbon and carbon nanotube structures have lower adsorption energies, which can improve carbon corrosion resistance.

Professor Seo Minho, the principal investigator, stated, "The fluorine-doped graphene nanoribbon and carbon nanotube composite, proven through the combination of experimental and computational science, will be an important strategy for efficiently and easily developing highly durable hydrogen fuel cells when used as an additive in electrodes."

This research was supported by the Pukyong National University Young Researcher Challenge Project, the Korea Institute of Energy Technology Evaluation and Planning, the Korea Institute for Advancement of Technology, and the Korea Institute of Materials Science. The results were published in an international journal with Jin Song, a doctoral student (Korea Institute of Materials Science/GIST), and Kwon Junhwa, Ph.D. (GIST), as first authors, and Dr. Choi Seungmok, Professor Um Kwangseop, and Professor Seo Minho as corresponding authors.

Electrochemical carbon corrosion accelerated life test evaluation of polymer electrolyte fuel cell system, with conventional electrode introduction (left) and electrode introduction proposed in this study (right).

Electrochemical carbon corrosion accelerated life test evaluation of polymer electrolyte fuel cell system, with conventional electrode introduction (left) and electrode introduction proposed in this study (right).

The research team is conducting follow-up studies to improve the performance and stability of polymer electrolyte fuel cell systems by developing core catalyst technologies such as new highly durable carbon supports, nanoparticle structure control, and electrode fabrication processes.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)