Next-Generation GAA, Foundry Game Changer

Focusing on Stable Technology Development Instead of Speed Race

Expecting Double-Digit Sales Growth in Q2

The core focus of Samsung Electronics' Foundry Forum held on the 12th (local time) this year was the stabilization of the cutting-edge processes outlined in the existing roadmap. Samsung Electronics has set a goal to mass-produce the 1.4㎚ (nanometer; 1㎚ = one billionth of a meter) process by 2027, and revealed plans to invest more resources into yield (the ratio of good products among finished products) and performance to ensure stable product supply to customers. Although there was speculation at this forum about the possibility of advancing the mass production timeline for the 1.4㎚ process, it is ultimately evaluated that Samsung reaffirmed its determination to lead the 1㎚ era by successfully following the roadmap.

The scene at the 'Samsung Foundry Forum 2024' held on the 12th (local time) in Silicon Valley, USA / Photo by Samsung Electronics

The scene at the 'Samsung Foundry Forum 2024' held on the 12th (local time) in Silicon Valley, USA / Photo by Samsung Electronics

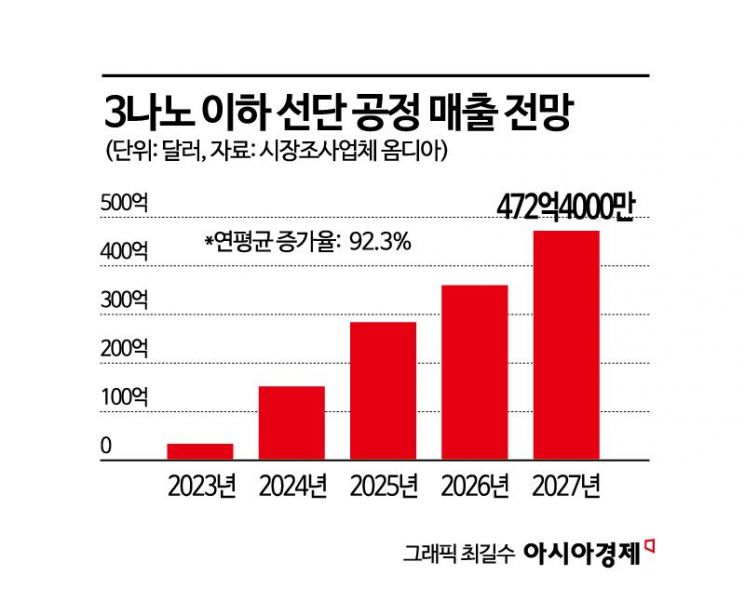

Samsung Electronics emphasized that it is enhancing its gate-all-around (GAA) technology, which was first introduced in the industry with the 3㎚ process in 2022. GAA is a next-generation technology that increases the number of surfaces where the transistor gate (the door through which current flows) and the channel (the path where current flows) meet from one to four. Compared to the existing transistor structure, FinFET, it offers faster data processing speeds and higher power efficiency, making it a game changer in the foundry industry. Samsung Electronics attracted attention by adopting GAA earlier than Taiwan's TSMC, the industry leader.

At the forum, Samsung Electronics stated, "We are currently mass-producing the first generation (SF3E) of the GAA-based 3㎚ process with stable yield," and added, "The second generation process (SF3) will also be developed without delay based on the mass production experience of SF3E and is scheduled for mass production in the second half of the year." They also explained, "Since the initial application of GAA technology, development is underway for the 2㎚ and 1.4㎚ processes."

Samsung Electronics' current stance differs from what was emphasized in forums over the past two years. In the 2022 forum, the company declared plans to mass-produce semiconductors using the 2㎚ process in 2025 and the 1.4㎚ process in 2027. Last year's event saw Samsung present a concrete 2㎚ process roadmap, the first in the industry ahead of Taiwan's TSMC. However, this time, rather than rushing the advanced semiconductor race, Samsung highlighted plans to improve GAA technology for business stability.

This is related to the fact that competitors TSMC and Intel have both announced plans to adopt GAA starting from the 2㎚ scale. Since TSMC has announced 2㎚ mass production in 2025, there is about a three-year technology adoption gap compared to Samsung Electronics. This means Samsung has effectively bought time to improve GAA yield.

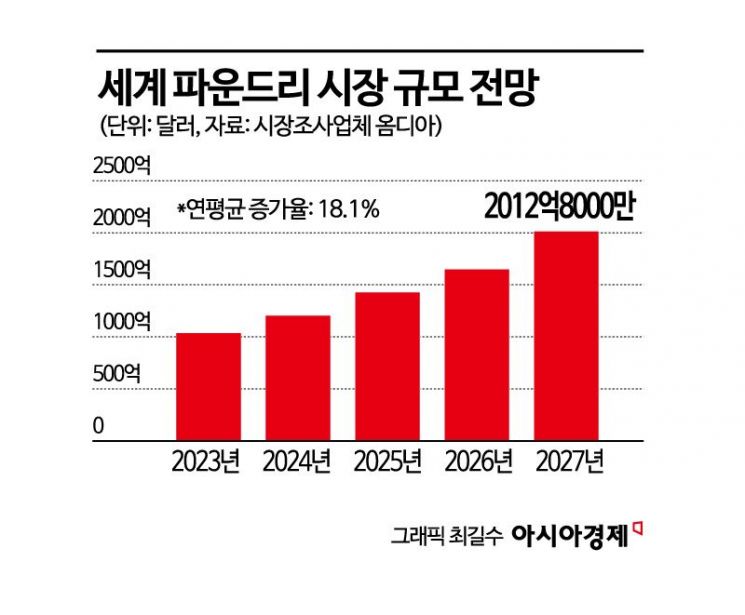

The foundry industry's 1㎚ roadmap is also underway. With the surge in demand for high-performance semiconductors due to the spread of artificial intelligence (AI) devices, foundry orders have rapidly increased, intensifying industry competition. Currently, the most advanced technology is the 3㎚ process showcased by TSMC and Samsung Electronics. Taiwan's TSMC, which had announced 1.4㎚ mass production in 2027, added a leading-edge process roadmap in April by announcing semiconductor production starting in 2026 with the 1.6㎚ process. U.S.-based Intel, chasing TSMC and Samsung Electronics, has ignited competition by announcing the introduction of 18A (approximately 1.8㎚) within this year.

Samsung Electronics has set a goal to increase the revenue share of product lines other than mobile in its foundry business to over 50% by 2027 through improvements in leading-edge process technology. The company reported that its AI-related orders, a representative high-performance computing (HPC) field, increased by 80% compared to last year. Last year, Samsung also secured mass production orders for next-generation AI chips from AI startups Groq and Tenstorrent.

According to this strategy, the number of Samsung Electronics' foundry customers is expected to expand from 100 in 2022 to 120 last year, then to 169 in 2026, and 210 in 2028. Samsung's foundry orders reached a record high of $16 billion last year. In the second quarter of this year, a double-digit sales growth rate is expected due to market improvements.

KB Securities stated, "The number of Samsung foundry customers is increasing by 10-15% annually through the expansion of the foundry ecosystem, including global IP companies (ARM, Cadence) and domestic design houses (Gaonchips, Semifive)," adding, "Samsung's foundry market share is estimated to reach 24% by 2028, doubling from 12% last year over five years."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)