"It has taken a full 10 years to pass through the tunnel of research. During the past years, we faced many difficulties and obstacles, but the fact that we were able to present the final results makes the challenging process meaningful."

This is the reflection of the research team members who developed the technology for 'metal-elastomer nanostructures' shaped like brain wrinkles.

On the 23rd, the National Research Foundation of Korea announced that an international joint research team consisting of Professor Tae-Il Lee from Gachon University, Professor Jin-Young Oh from Kyung Hee University, Dr. Won-Jin Choi from Lawrence Livermore National Laboratory, and Professor Soo-Sang Chae from Korea University of Technology and Education developed a technology to create metal-elastomer nanostructures using a kinetic method.

This technology enables the creation of advanced bio-new materials that stretch like rubber while conducting electricity as freely as metal. The nanostructure increases the surface area of the material, resembling brain wrinkles, resulting in a highly durable and stretchable electrode material.

The 'kinetic method' approached by the joint research team during the study played a crucial role in overcoming the material limitations where metal substances and elastomers like rubber do not mix.

The kinetic method refers to the field that explores the pathways and rates of chemical reactions. It is distinguished from thermodynamics, which explains the principles related to energy transformation and flow in chemical reactions.

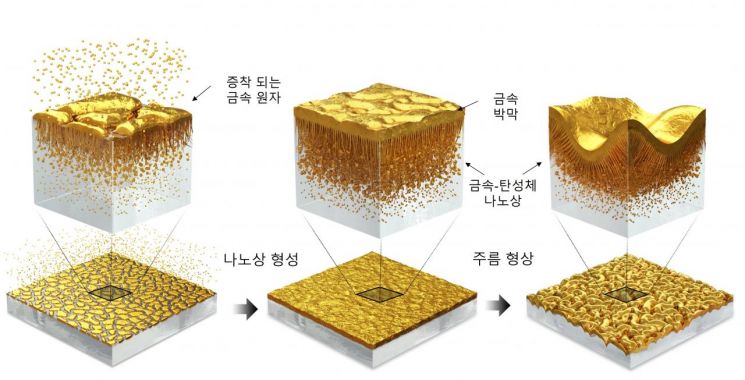

The joint research team controlled the chemical reaction by adjusting the deposition rates of metal and rubber elastomer during the process of depositing (adhering) a metal thin film onto a rubber elastomer substrate (kinetic method). This allowed them to create a densely connected metal-elastomer nanophase that retains the unique properties of each material, which is difficult to mix thermodynamically.

Additionally, the metal-elastomer nanophase formed on the surface of the completed rubber elastomer substrate induced mechanical instability at the interface with the substrate, leading to the formation of surface wrinkles resembling brain folds over several hours after deposition.

This means that while achieving an increased surface area, the unique nanostructure inside the metal-elastomer nanophase exhibits exceptionally high durability in mechanical, chemical, and thermal aspects, which is rarely seen in conventional materials.

Metal-nano phase formation process. Provided by Professor Chaesu Sang, Korea University of Technology and Education

Metal-nano phase formation process. Provided by Professor Chaesu Sang, Korea University of Technology and Education

The research results are expected to provide a clue to overcoming the material limitations where metal substances and elastomers like rubber do not mix due to repulsive forces, especially in the current active development of wearable electronic devices such as electronic skin and wearable robots.

Wearable electronic devices require electronic skin resembling human skin, tactile sensors, and flexible displays. Since materials that conduct electricity and are flexible are essential to create these, the joint research team's findings are attracting attention.

Professor Soo-Sang Chae said, "We expect that the joint research team's achievements, based on durability that existing stretchable electrodes could not have, will be widely used as electrode materials in next-generation wearable medical devices, electronics, VR, and other application fields."

Meanwhile, the joint research team conducted the study with support from the New Researcher Project promoted by the Ministry of Science and ICT and the National Research Foundation of Korea. The research results were published on the 9th in the international materials science journal Nature Communications.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)