"Component Properties Can Be Changed Whenever Needed"

Professor Kim Ji-yoon's Team Surpasses Limits of Existing Materials

What if you could change the shape of a part used in a machine whenever needed?

A material that can change its shape and properties in real time has been developed. This material can be used as a core component in various machines such as robots that require adaptation to dynamic changes or deformation of shape.

UNIST (President Yong-Hoon Lee) announced on the 5th that a research team led by Professor Ji-Yoon Kim from the Department of Materials Science and Engineering has developed the world’s first metamaterial that can control the shape and characteristics of a material in real time, surpassing the limitations of existing materials.

Unlike existing metamaterials whose designed shapes and properties could not be changed or only changed in a limited way, this new material can be used in real time as needed.

Metamaterials are artificial materials designed to have special physical properties unlike ordinary materials found in nature. For example, ordinary materials like jelly expand horizontally when compressed vertically, but metamaterials can contract horizontally even when compressed vertically. Such properties can be innovatively applied in various fields such as architecture, aerospace, and robotics.

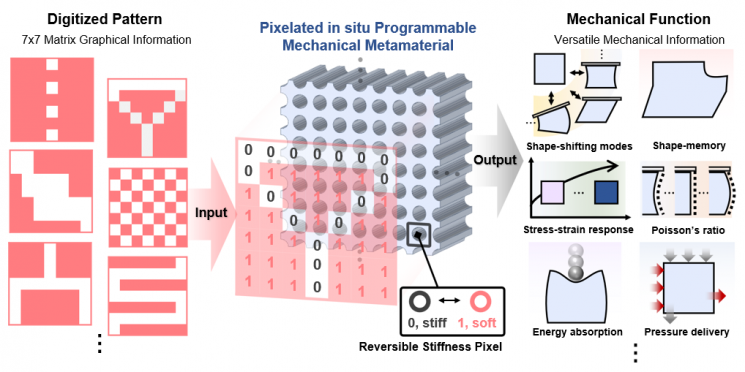

The research team succeeded in developing a metamaterial that can adjust its shape and material properties in real time. According to the team, they fused a low-melting-point alloy, which can change between typical states of matter such as liquid and solid, into the metamaterial’s basic unit structure called a meta-pixel.

By controlling the state changes of the fused alloy at the small pixel unit level, they were able to realize various properties of the metamaterial.

The team designed the fused alloy to represent digital pattern information (0=liquid, 1=solid) and to allow real-time input of digital pattern commands. Through the input digital patterns, various properties of the metamaterial such as shape, strength, and deformation ratio can be adjusted in real time.

Jung-Kyu Choi, a first author and integrated MS-PhD course researcher, explained, “The developed metamaterial realized desired properties within minutes without additional hardware,” adding, “It will present new possibilities for advanced adaptive materials, including the development of adaptive robots.”

As an example of utilizing the developed metamaterial, the research team demonstrated an ‘adaptive shock energy absorption material.’ This metamaterial changed its properties appropriately according to shocks occurring in unpredictable situations. It minimized the force transmitted to the protected object, reducing the possibility of damage or injury.

Additionally, the team used the metamaterial as a ‘force transmission material’ that can deliver force to desired locations and times. According to commands input into the metamaterial, force was applied to one side. When the path of the applied force was digitally commanded, it was confirmed that adjacent LED switches on the opposite side could be selectively activated.

Professor Ji-Yoon Kim of the Department of Materials Science and Engineering said, “This metamaterial, which can convert digital information into physical information in real time, is compatible not only with various existing digital technologies and devices but also with artificial intelligence technologies such as deep learning,” adding, “An innovative new material that can learn by itself and adapt to its surrounding environment has taken its first step.”

This research was officially published on January 25 in the internationally renowned journal Advanced Materials and was selected as a cover paper. The research was supported by the Ministry of Science and ICT’s National Research Foundation of Korea (NRF) and the Korea Institute of Materials Science (KIMS).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)