First Operation at Pohang 1 Steelworks in 1973

June 9 Designated as 'Steel Day'

Technology Without Coal Usage

Developing Hydrogen Reduction Steelmaking

Demo Plant Construction in 2026

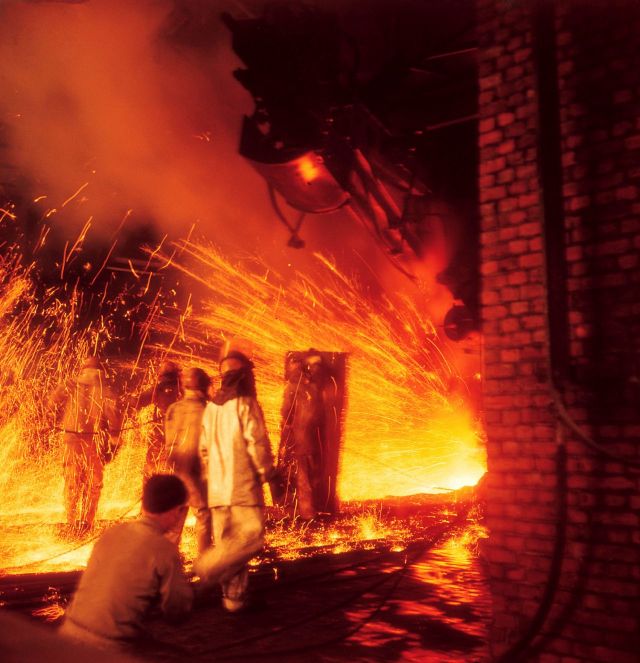

On the 9th, POSCO's 'Molten Steel Legend' marked its 50th anniversary. At 7:30 a.m. on June 9, 1973, the No. 1 blast furnace at the Pohang Steelworks in Gyeongbuk roared to life, pouring out its first molten steel. It was the moment South Korea took its first step toward industrialization.

The first molten iron poured from Pohang Steelworks Blast Furnace No. 1 on June 9, 1973 [Photo courtesy of POSCO]

The first molten iron poured from Pohang Steelworks Blast Furnace No. 1 on June 9, 1973 [Photo courtesy of POSCO]

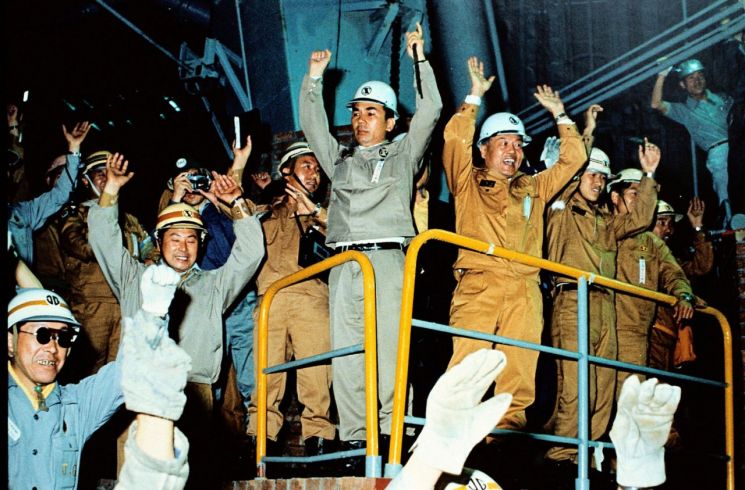

The late Park Tae-joon, Honorary Chairman of the POSCO Group, said at the fire-lighting ceremony for the blast furnace the day before, “You have achieved a feat that will be remembered in history, and you are a lifesaver to me.” From the first tapping in 1973 until 2022, the cumulative crude steel production at Pohang Steelworks reached 552.95 million tons. The Steel Association designated June 9, the day molten steel was first produced, as 'Steel Day.'

On this day, POSCO will hold an internal event presided over by Lee Baek-hee, the head of Pohang Steelworks. Former Pohang Steelworks heads will be invited to tour the in-house complex cultural space Park1538 and the startup incubation space ChangeUpGround in the morning, and in the afternoon, a homecoming day will be held with about 3,000 Pohang employees, including retirees.

On June 9, 1973, after the first steel casting at the Pohang Steelworks, the late Park Tae-joon, Honorary Chairman of the POSCO Group, and employees are cheering.

On June 9, 1973, after the first steel casting at the Pohang Steelworks, the late Park Tae-joon, Honorary Chairman of the POSCO Group, and employees are cheering. [Photo by POSCO]

Pohang Steelworks, South Korea's first integrated steel mill, began construction in April 1970 and was completed in March 1973. It invested $119.48 million from the Japan-Korea Claims Settlement Fund. Chairman Park expressed the sentiment of having no choice but to use the Japan-Korea Claims Fund in a situation lacking both technology and capital as follows: “This steel mill is being built with the Japan-Korea Claims Fund, which is the price paid in blood by our ancestors. If we fail, we will have committed an unforgivable sin before history and the people. At that time, we must turn east and throw ourselves into Yeongil Bay.”

POSCO currently operates a total of eight blast furnaces: three at Pohang Steelworks and five at Gwangyang Steelworks. The No. 1 blast furnace at Pohang Steelworks, which rewrote steel history, was shut down in December 2021 after 48 years and 6 months of operation. The 55.2 million tons of molten steel produced by the No. 1 blast furnace is enough to make 55.2 million mid-sized cars. A POSCO official said, “Since the capacity was expanded during regular maintenance of the blast furnace to increase output, the tapping volume will not decrease even after the No. 1 blast furnace’s shutdown (Jongpung, the extinguishing of a blast furnace at the end of its life).”

On April 1, 1970, former President Park Chung-hee, former Deputy Prime Minister Kim Hak-ryul, and Honorary Chairman Park Tae-joon are walking toward the groundbreaking ceremony site of the Pohang Steelworks.

On April 1, 1970, former President Park Chung-hee, former Deputy Prime Minister Kim Hak-ryul, and Honorary Chairman Park Tae-joon are walking toward the groundbreaking ceremony site of the Pohang Steelworks. [Photo by POSCO]

In 2021, POSCO achieved record-breaking results with crude steel production of 45.33 million tons, sales of 76.3323 trillion won, and operating profit of 9.2381 trillion won. Both sales and operating profit surpassed 70 trillion won and 9 trillion won respectively for the first time since the company's founding.

Last year, Pohang Steelworks faced its greatest crisis ever. Due to Typhoon Hinnamnor, the nearby Naengcheon stream overflowed, flooding an area three times the size of Yeouido around the plant. The three blast furnaces, covered in mud, stopped operating for the first time in 49 years since their first molten steel production. Defying experts’ expectations that it would take at least six months to restore the plant, POSCO resumed normal operations of all plants in just 135 days on January 19.

Last September, employees are sweeping the muddy water-covered material warehouse at Pohang Steelworks, which was directly hit by Typhoon 'Hinnamnor'.

Last September, employees are sweeping the muddy water-covered material warehouse at Pohang Steelworks, which was directly hit by Typhoon 'Hinnamnor'. [Photo by POSCO]

The keyword for the next 50 years of Pohang Steelworks is eco-friendliness. On the 55th anniversary of POSCO Group’s founding last April, Chairman Choi Jeong-woo said, “We are growing beyond the world’s top steel company to become a global leader in eco-friendly future materials,” adding, “We will create a new future toward becoming a 100-year company.”

POSCO is developing hydrogen reduction steelmaking technology, a steelmaking process that does not use coal. Currently, basic design work is underway, and in 2026, a portion of the Pohang Steelworks plant will be remodeled to install a demonstration-scale demo plant. The goal is to complete technology development by 2030, gradually convert existing processes to hydrogen reduction steelmaking, and achieve net zero by 2050.

Choi Jung-woo, Chairman of POSCO Group, visited the National Seoul National Cemetery in Dongjak-gu, Seoul, on April 3rd to commemorate the group's 55th anniversary and the 50th anniversary of the completion of the first phase of the Pohang Steelworks. He paid respects at the grave of Park Tae-joon, the founding chairman.

Choi Jung-woo, Chairman of POSCO Group, visited the National Seoul National Cemetery in Dongjak-gu, Seoul, on April 3rd to commemorate the group's 55th anniversary and the 50th anniversary of the completion of the first phase of the Pohang Steelworks. He paid respects at the grave of Park Tae-joon, the founding chairman. [Photo by POSCO]

Kim Jae-dong, Senior Researcher at POSCO’s Low Carbon Steelmaking Research Institute, said, “We plan to eliminate facilities that create the intense heat and melting (the process of solid turning into liquid by heat) of iron ore like a blast furnace and introduce electric furnaces,” adding, “Hydrogen reduction will be applied directly to the ‘FINEX’ fluidized reduction furnace, which has been operating at Pohang Steelworks for over 15 years.” He continued, “In the existing blast furnace, coal combustion gas was used to remove oxygen attached to oxide iron ore (reduction) and to melt it, but by utilizing POSCO’s developed ‘HyREX’ technology, reduction can be done with hydrogen and melting with electric furnaces.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)