"This facility is capable of producing not only immune cell therapeutics but also immune cell gene therapies."

On the afternoon of the 23rd, Kim Taegyu, CEO of VigenCell, made this statement while introducing VigenCell’s ‘Advanced Biopharmaceutical GMP Center’ located in Geumcheon-gu. Good Manufacturing Practice (GMP) standards define the management criteria required throughout all processes in a factory?from raw material procurement to manufacturing and shipment?to ensure the production of high-quality pharmaceuticals.

VigenCell’s investment in the GMP center is aimed at full-scale commercial pharmaceutical manufacturing. The GMP facility previously used at the Catholic University did not have manufacturing approval for advanced biopharmaceuticals, causing production disruptions. The lack of production facilities for clinical trial drugs also had an impact.

VigenCell’s GMP center is equipped with a full-cycle system capable of producing messenger ribonucleic acid (mRNA), cell therapeutics, and cell gene therapeutics, as well as peripheral blood banking. Construction began in October 2021 and was completed in April last year. VigenCell invested a total of 21 billion KRW in establishing the facility. After completion, the company obtained manufacturing approval for advanced biopharmaceuticals from the Ministry of Food and Drug Safety in July last year, followed by GMP certification for in vitro diagnostic medical devices in December. With the GMP center, the company can now produce clinical and commercial drugs in-house, accelerating clinical trials and research and development (R&D). This is possible because the GMP center is equipped to simultaneously produce cell therapeutics and cell gene therapeutics.

The VigenCell GMP center, toured on this day, showed clear signs of meticulous consideration to meet stringent production and testing standards. First, all areas of the GMP center are secured with a fingerprint recognition system for entry. Given that it is a pharmaceutical manufacturing facility, great care was taken to prevent contamination. The company applied individual air conditioning systems to all areas to completely block any possible contamination. The main research is conducted in seven GMP-certified aseptic processing rooms (clean rooms), which can only be entered after disinfection and changing clothes. There were three mandatory disinfection steps before entering the aseptic processing rooms, so the press visiting the site were restricted from entering the clean rooms. Inside the aseptic processing rooms, researchers fully covered in dust-proof suits, goggles, and masks were deeply engaged in their work.

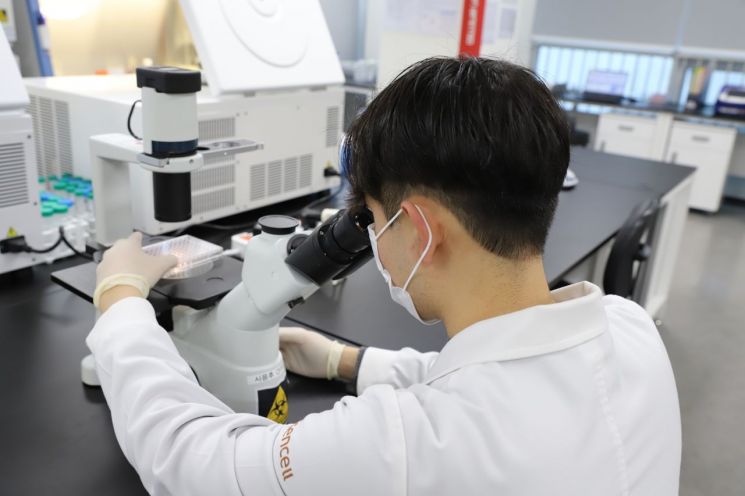

A researcher is producing clinical trial drugs at the Bygensel Advanced Biopharmaceutical GMP Center.

A researcher is producing clinical trial drugs at the Bygensel Advanced Biopharmaceutical GMP Center. [Photo by Bygensel]

VigenCell was established in 2013 as the first subsidiary of the Catholic University Technology Holdings Company and specializes in immune cell therapeutics. CEO Kim, an expert in immunology, microbiology, and molecular cell biology, has led the company since its founding. VigenCell has secured three immune cell therapeutic platforms with immune-enhancing and immune-regulating functions. Specifically, there is ‘Vitiar,’ a T-cell therapy platform technology that selectively eliminates only cancer cells, and ‘Vireinjer,’ a gamma delta T-cell gene therapy platform that targets and removes abnormal cells. The immune suppressant ‘Vimedier’ is based on immune-suppressive cell therapy technology differentiated and proliferated from myeloid-derived suppressor cells derived from umbilical cord blood stem cells.

Currently, the company has expanded its business to include in vitro diagnostic medical devices. The gene-related product line plans to commercialize a T-cell receptor rearrangement analysis diagnostic kit using next-generation sequencing (NGS). The disease diagnostic test product line helps optimize drug prescriptions by identifying the genetic characteristics of patients.

CEO Kim stated, "The GMP center is optimized for process development and is a facility capable of producing not only immune cell therapeutics but also immune cell gene therapies." He added, "I have visited many foreign research institutes, but I am proud of the facilities and structure of VigenCell’s GMP center." He further pledged, "Although biopharmaceutical development involves long periods and risks, we will endure all difficulties and commit to developing therapeutics to help patients with intractable diseases."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.