[Why Have School Uniforms Become Outcasts?]

Visiting Gukdo Textile School Uniform Factory

About 140 Employees in a Division of Labor System

"Need for Quality and Material Competition Among Companies"

Unified Call for Improvement of School Uniform Purchase System

A worker is making a winter jacket at 'Gukdo Textile,' a school uniform manufacturer in Busan. During the busy months of January and February, they also work on weekends. Photo by Kim Bo-kyung bkly477@

A worker is making a winter jacket at 'Gukdo Textile,' a school uniform manufacturer in Busan. During the busy months of January and February, they also work on weekends. Photo by Kim Bo-kyung bkly477@

[Asia Economy Reporter Kim Bo-kyung] "We put our utmost sincerity into making school uniforms. From the maker's perspective, they are by no means expensive."

This is what Kim Yoon-ho, CEO of Gukdo Textile in Busan, who has specialized in producing school uniform jackets for 16 years, stated. Gukdo Textile has contracts with school uniform brands such as Smart and supplies jackets to 700 to 800 middle and high schools annually. During this season before the new semester, they produce about 1,000 jackets in an 8-hour workday. CEO Kim said, "School uniforms must reflect each school's honor and identity, so the designs vary," adding, "The details are diverse, making it a very labor-intensive task." Recently, as schools compete to have stylish and attractive designs, school uniforms have become more fashion-oriented, making the work "simply a headache," he said with a laugh.

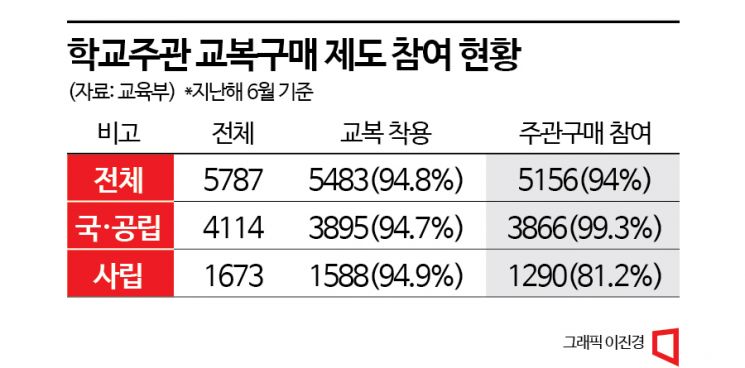

Another factor contributing to price increases is that school uniforms are a typical example of multi-product small-lot production. There are about 5,000 middle and high schools nationwide that require uniforms, with each school having around 100 to 200 students. According to CEO Kim, they have to produce tens of thousands of garments because each student’s measurements vary and there are six types of pieces such as jackets, vests, and shirts. Due to the nature of school uniform transactions in the public procurement market, if even some students in the entire school do not receive their uniforms, the company faces financial penalties. CEO Kim said, "We work with pride under the conviction that these uniforms are for the students," and added, "It pains me to see school uniforms treated as if they have no value."

There is also a sense of pride that school uniforms must be made domestically, which makes low-cost production like typical SPA brands impossible. His factory employs about 140 workers, with no foreign laborers. During the busy months of January and February, employees even work on weekends. This is an overtime system to deliver uniforms to stores nationwide by the end of February before students enter school. Touring the 600-pyeong (approximately 2,000㎡) factory on the third floor of the building, automated fabric cutting equipment was installed, and employees operated under a strict division of labor. Each garment is sewn by hand, fitted, and finished by removing loose threads. School uniform production clearly requires a lot of manual labor. CEO Kim said that labor costs account for about 40% of the product cost. These uniforms are made stitch by stitch and even carry the Q Mark (quality certification), so why have quality controversies such as "wearing out quickly" and "seams easily tearing" arisen?

Reasons for Quality Controversies? "Low-price Bidding, Tight Production Schedules"

CEO Kim cited fierce low-price bidding competition among companies as the main cause of claims that "school uniform quality is low." Since the implementation of the school-led school uniform purchasing system in 2015, low-price bidding competition has intensified. Over 1,100 school uniform dealerships nationwide competitively lower prices to win contracts with schools. CEO Kim said, "When awarded at a low price, companies use lower-quality raw materials to minimize losses considering inventory," emphasizing, "Unless this system changes, quality cannot improve."

He also mentioned that the difficulty is exacerbated because labor costs and raw material prices are not reflected in the school uniform price ceilings set annually by each city and provincial education office. In this regard, from the second half of this year, a supply price linkage system will be implemented in the private sector, allowing small and medium enterprises to reflect raw material price increases when supplying products to large companies. However, since school uniform supply in the public procurement market is subject to local contract laws, there is currently no legal basis to implement the supply price linkage system.

CEO Kim said that if schools announce uniform bidding notices late, production schedules inevitably suffer. "When you rush to write an article, you make typos and the content becomes poor, right? It's the same with school uniforms." Uniforms must be delivered to stores by the end of February, but if schools announce bidding notices late, even running the factory overnight results in a tight situation. The Ministry of Education recommends that city and provincial education offices issue bidding notices by August each year, and education offices pass this on to schools. However, the Korea School Uniform Industry Association reported that only 23% of schools issued notices by August last year. There were even 316 schools that issued notices late in December last year. CEO Kim said, "If delivery deadlines are not met, it becomes difficult to participate in that school's bidding the following year."

Gukdo Textile employees work only eight months a year. The factory closes for four months from June to September when there is no school uniform work. During this period, employees receive unemployment benefits to support their livelihood. CEO Kim said, "I want to operate the factory year-round, but since work is concentrated in specific periods, it is not possible," adding, "If the bidding period is moved earlier, it could reduce the waste of national tax money spent on unemployment benefits."

"We Must Improve School Uniform Design and Quality Through Fair Competition"

Jung Hyun-jeung, Secretary General of the Parents' Association Loving Schools (Haksa-mo), said, "While expensive school uniforms were the problem during the autonomous purchasing era, quality issues are now an urgent issue that must be resolved." He has been involved in the field since before the school-led school uniform purchasing system began and currently serves as the chair of the school uniform investigation committee. Although the controversy over high-priced uniforms costing nearly 500,000 won per set has subsided, dissatisfaction among parents has grown due to the production of low-quality uniforms.

Secretary General Jung argued, "The price ceiling for school uniforms should be set at a reasonable level, but the system should allow parents to choose and purchase at stores." This would encourage competition among companies in quality and materials, ensuring students wear high-quality uniforms. He said, "Under the current system, where winning bids only need to be lower than the ceiling price, there is virtually no need to improve quality." He diagnosed that fair competition should raise design and quality, but currently, only cutthroat price competition remains. He also mentioned that some local governments operate a "free sportswear" system and distribute sportswear subsidies, but since there is no price ceiling, prices tend to rise.

Both parents and the school uniform industry agree that the school-led school uniform purchasing system, now in its ninth year, needs revision. Kim, who runs a school uniform company in Incheon, said, "Competition has become so intense that profits are not made, and as companies are eliminated, collusion becomes inevitable," lamenting, "This system forces people into desperate situations where they might think of unethical actions." He predicted that another side effect following collusion would be overseas production in China, Southeast Asia, and other regions. Kim appealed, "The school uniform market is the last stronghold of Korea's sewing industry," and urged, "Please protect the jobs of the few remaining skilled workers and small school uniform businesses."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)