KIGAM Develops Process for Separation, Selection, and Recovery of Cathode Material

As the prices of secondary battery raw materials such as lithium and graphite are soaring, a domestic research team has developed a technology that can recover and recycle more than 98% of these scarce raw materials from waste batteries.

The Korea Institute of Geoscience and Mineral Resources (KIGAM) announced on the 31st that a research team led by Dr. Yookwangseok from the Mineral Resource Utilization Research Division succeeded in developing a process to separate and recover cathode materials from black powder generated during the disassembly of waste lithium-ion batteries.

Black Powder is the powder produced by separating waste batteries down to the cell level and finely crushing them. It consists of cathode materials such as lithium metal oxides (Li-Metal Oxide, Metal: nickel, cobalt, manganese, etc.), anode materials such as graphite, metal electrodes (foil) like aluminum and copper, small amounts of electrolyte solution, carbon black, and binders.

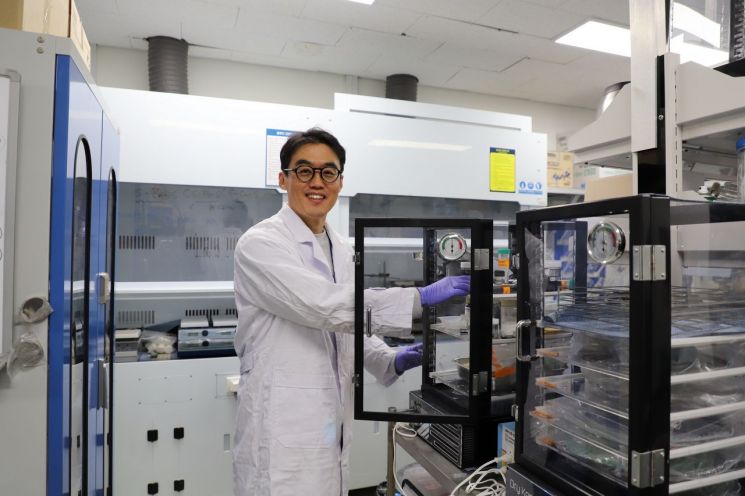

Dr. Kwangseok Yoo of the Korea Institute of Geoscience and Mineral Resources (KIGAM) developed a technology that can recover and recycle over 98% of cathode material raw substances such as lithium from waste batteries. Photo by KIGAM

Dr. Kwangseok Yoo of the Korea Institute of Geoscience and Mineral Resources (KIGAM) developed a technology that can recover and recycle over 98% of cathode material raw substances such as lithium from waste batteries. Photo by KIGAM

The particle size of the cathode materials separated in bulk within the black powder is less than 20 micrometers, and losses of cathode materials occur due to entrainment phenomena during the general flotation separation process.

The research team utilized the flotation separation process, a mineral separation method, and developed a "process and operational technology for recovering cathode materials contained in black powder from waste lithium-ion batteries." In particular, to minimize losses caused by entrainment phenomena of cathode materials smaller than 20 micrometers, they developed operating conditions that control the flotation circuit, optimal slurry concentration, reaction (residence) time, particle flow, and bubble layer thickness.

Based on this, the research team succeeded in recovering more than 98% of the cathode materials contained in black powder from waste lithium-ion batteries. The separated cathode materials include lithium metal oxides such as lithium, nickel, cobalt, manganese, and metal electrodes such as aluminum and copper. The key control factors of the research process are slurry concentration, slurry input and output (flow rate), stirring speed, reagent input, and air input. These key process factors can be maintained in an optimal state by applying "ICT-based flotation separation control technology."

With the success of this technology development, it is expected that domestic recycling companies will significantly improve the efficiency and productivity of high-purity refining processes that recover ternary materials (nickel, cobalt, manganese, etc.) such as lithium from cathode materials derived from black powder, and greatly contribute to reducing operating costs.

Dr. Yookwangseok said, "The technology and process developed this time will greatly contribute to securing the competitiveness of domestic companies based on technological differentiation from overseas companies such as those in China," adding, "We will strive to advance this technology, transfer and commercialize it to domestic companies, and secure the national battery industry's competitiveness through continuous technical support."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.