[Asia Economy Reporter Choi Dae-yeol] Automotive parts manufacturer KBI Dongguk Industrial announced on the 28th that it has applied a newly developed automated technology for the artificial leather (PU, polyurethane) finish of the crash pad used in Hyundai Motor's new Grandeur.

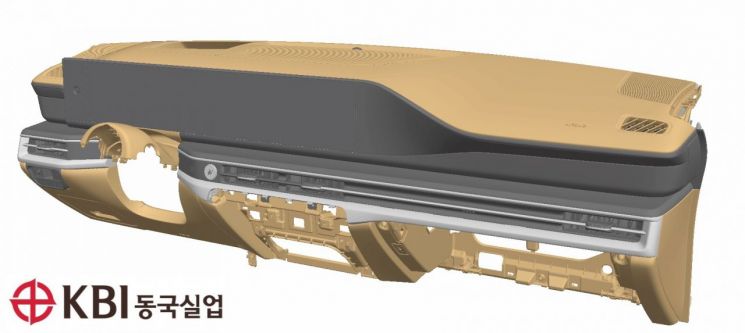

The crash pad is a device that covers the engine compartment area in front of the driver and passenger seats inside the vehicle. It is considered an important part not only for driver safety but also for the interior atmosphere of the vehicle. It is also one of KBI Dongguk Industrial's main products.

According to the company, the crash pad upper panel was previously wrapped with artificial leather by hand. The new Grandeur applies an automated process developed by the company called ‘PU Skin In-Mold Grain (IMG)’.

The company invested 1 billion KRW over about two years since 2019 to develop this new process. The previous technology had the disadvantage that quality depended on the skill level and individual differences of workers due to the manual process. The new technology automates production through skin molding and compression molding or skin molding, sewing process, and compression molding, achieving the same appearance as existing products while providing a soft texture and a luxurious impression, the company explained.

Additionally, the company stated that the defect rate was improved by about 70% and costs were reduced by 30%. They have filed five IMG-related patents domestically and five internationally, and plan to apply this technology to future mass-produced vehicles from Hyundai and Kia.

Kim Jin-san, CEO of KBI Dongguk Industrial, said, "We will continue to invest in developing products with excellent moldability that preserve the moist and soft texture and gloss of the crash pad upper panel in collaboration with fabric manufacturers."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)