Korea Institute of Materials Science

[Asia Economy Reporter Kim Bong-su] Domestic researchers have developed the world's first core material necessary for the commercialization of 6G communication technology. 6G communication uses the extremely high frequency (EHF) band for transmission speeds 50 times faster than 5G, requiring control of millimeter wave (30~300GHz) electromagnetic signals to prevent noise, interference, and ensure security. Electromagnetic wave absorbing materials are essential for this purpose. Although research has been ongoing worldwide, materials capable of absorbing frequencies in the terahertz band above several tens of GHz have not yet been developed.

The Korea Institute of Materials Science (KIMS) announced on the 22nd that the research team led by Dr. Baek Yeon-gyeong and Dr. Lee Jeong-gu from the Magnetic Materials Research Division of the Powder Materials Research Center successfully developed the world's first continuous manufacturing technology for epsilon iron oxide with millimeter wave absorption functionality and high coercivity comparable to neodymium (Nd) magnets.

Magnetic materials that absorb ultra-high frequencies corresponding to the 6G band are almost exclusively iron oxide materials with the epsilon crystal phase exhibiting high coercivity. However, until now, this phase could only be realized in nanoparticle form smaller than 50nm. Japan produced pure epsilon iron oxide through wet processes, but commercialization has been difficult due to low yield and multi-step process limitations.

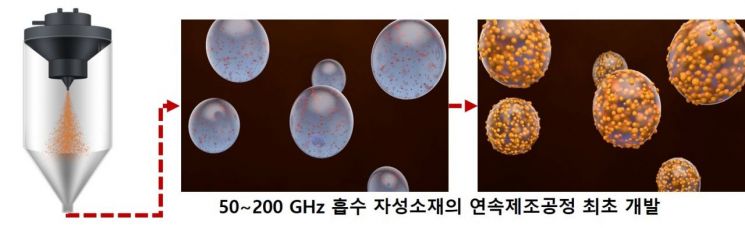

The research team solved the low yield manufacturing problem through an aerosol process. By spray drying and heat treating a precursor solution of iron and silicon in a thermal pressurized chamber, they succeeded in producing composite powder in which epsilon iron oxide nanoparticles are embedded in silica particles. When the raw solution is continuously injected and the spray solution is instantaneously dried, the iron precursor is trapped in zero-gel particles, limiting particle growth during heat treatment. This enabled continuous manufacturing of epsilon iron oxide nanoparticles using a powder manufacturing process on the micrometer scale, demonstrating significant potential for the commercialization of millimeter wave absorbing materials.

Compared to existing electromagnetic wave absorbing materials that show reduced absorption capacity or difficulty controlling frequency bands at high frequencies, epsilon iron oxide with absorption capability in the extremely high frequency (30~200GHz) band has high potential as a future communication component material. The continuous manufacturing technology for epsilon iron oxide with millimeter wave absorption can be applied to 5G/6G wireless communication and low-earth orbit satellite communication components based on millimeter waves, stealth technology, radar sensors, and as a high coercivity magnetic material, it can also be utilized in electronic components for future mobility.

Currently, no company mass-produces and applies magnetic materials capable of millimeter wave absorption to products, and only two to three companies in the US, Japan, and Germany produce absorption shielding materials for the 5G band. This technology development is expected to not only replace imports through domestic production but also enable exports overseas.

Principal researcher Baek Yeon-gyeong stated, "It is significant that we have developed the world's first continuous manufacturing process capable of selectively absorbing broadband (30~200GHz) ultra-high frequencies and suitable for commercialization," adding, "We expect this to accelerate the commercialization of absorption technologies for wireless communication devices using millimeter waves, autonomous vehicle radar, and space satellite communications." The research team is currently discussing technology transfer for mass production of iron oxide absorption materials with multiple companies and conducting additional research on enhancing terahertz wave absorption above 100 gigahertz (GHz).

The research results were published on September 22 in the materials science journal Chemical Communications, issued by the Royal Society of Chemistry in the UK.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)