[Asia Economy Yeongnam Reporting Headquarters, Reporter Hwang Du-yeol] A research team led by Professor Jeong Im-du of the Department of Mechanical Engineering at UNIST has developed a technology that virtually manufactures ‘3D shapes of metal surfaces’ by applying artificial intelligence (AI) based on real data.

The ‘Direct Energy Deposition (DED) process,’ a type of 3D printing technique, is useful for manufacturing large metal parts such as rocket components or repairing damaged parts that are difficult to fix without further machining.

Although the process can achieve high strength and elongation, it is known to be difficult to control surface characteristics that significantly affect fatigue properties.

Therefore, unless an expert who has extensive experience with the equipment is involved, it is challenging to easily obtain high tensile strength, elongation, and ‘specific surface shapes.’ Especially when using expensive materials like titanium, significant process development costs are incurred.

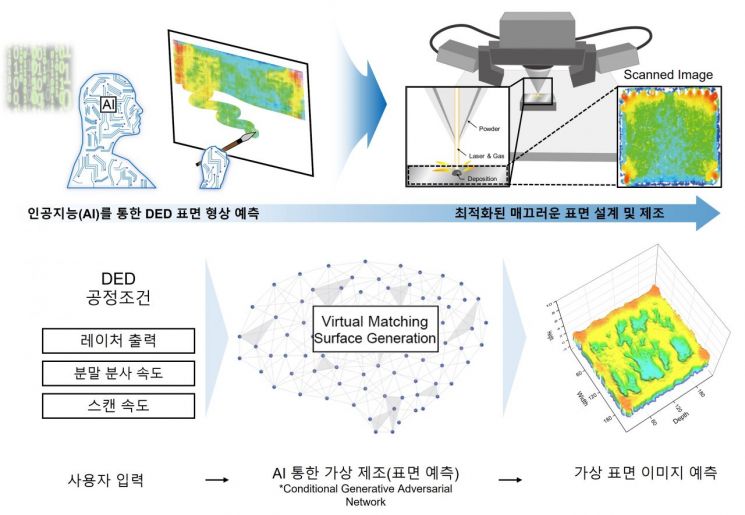

In response, the research team developed a technology that allows even non-experts to easily obtain desired surface characteristics by having AI virtually generate expected surfaces according to DED process conditions.

The AI learned surface scan images based on DED process parameters such as laser power, powder injection speed, and scan speed, and generated expected virtual 3D surfaces for arbitrary process inputs.

As a result, it rapidly created expected metal surface images within seconds under various process conditions. These images accurately represented the characteristics of metal surfaces manufactured by the same actual process, and surfaces produced under AI-recommended process conditions also exhibited excellent microstructural properties.

Kim Tae-kyung, a combined master’s and doctoral course researcher in the Department of Mechanical Engineering at UNIST and the first author of the paper, said, “The virtual metal surface manufacturing AI developed in this study can predict the results of difficult and complex manufacturing processes like the DED process very closely to reality,” adding, “With continuous accumulation and learning of manufacturing databases, it will help new operators who are not equipment experts to easily and quickly achieve high quality.”

Professor Seong Hyo-kyung of Kookmin University, a co-corresponding author, explained, “Expensive materials such as titanium alloys incur high initial costs during process development,” and added, “The AI virtual manufacturing technology realized through this research can drastically reduce material development costs.”

Professor Jeong Im-du of the Department of Mechanical Engineering at UNIST, who oversaw the research as the corresponding author, said, “In manufacturing, quality often depends heavily on the skill level of the operator, and the absence of skilled workers can cause operational disruptions,” emphasizing, “The more technologies like virtual manufacturing AI are developed, the more they can reduce quality variations due to operators and contribute to ultimate productivity improvement through digitalization.”

This research was conducted jointly with Carnegie Mellon University, Georgia Institute of Technology, Gyeongsang National University, and Kookmin University, and was supported by the Basic Research Support Project of the National Research Foundation of Korea.

The research results were published in ‘Virtual and Physical Prototyping,’ an international journal ranked within the top 5% in the manufacturing field according to the JCR.

(From left) Seong Hyo-kyung, Professor of the Department of New Materials Engineering at Kookmin University; Kim Tae-kyung, Integrated Master's and Doctoral Course Researcher in the Department of Mechanical Engineering at UNIST; Professor Jeong Im-du.

(From left) Seong Hyo-kyung, Professor of the Department of New Materials Engineering at Kookmin University; Kim Tae-kyung, Integrated Master's and Doctoral Course Researcher in the Department of Mechanical Engineering at UNIST; Professor Jeong Im-du.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)