[Asia Economy Reporter Jeong Dong-hoon] Korea's shipbuilding industry is sweeping up global orders with eco-friendly vessels such as LNG (liquefied natural gas) carriers and propulsion ships. However, the workforce that left during the prolonged downturn is not returning. Despite having work, it is difficult to find people to work, leading to a "cry of agony amid the boom."

There is widespread concern that the industrial ecosystem of large shipbuilders and their partners could collapse due to labor shortages. There are calls both inside and outside the industry to break the low-wage structure, attract young talent, and create workplaces worth working in. Experts point out that above all, it is important for companies to regain profits and create the capacity to raise wages.

According to the Korea Shipbuilding & Offshore Plant Association on the 14th, 60,336 workers are needed as of September this year to handle order volumes, but a shortage of 9,509 workers is expected. The anticipated shortage will increase to 11,099 by June next year.

Professor Lee Jang-hyun of Inha University’s Department of Naval Architecture and Ocean Engineering diagnosed, "(Shipbuilders) want to raise wages, but currently the market is tilted toward the demand side (shipowners)." He added, "Shipbuilding is a made-to-order industry like a tailor shop, so shipbuilders are pulled along by the orders and contracts of these customers." He emphasized, "It is important for companies to increase productivity and advance technology to create a structure that can generate profits."

He said, "Efforts are needed not only in automation facilities but also in developing technologies such as artificial intelligence (AI), Internet of Things (IoT), and big data analysis to shorten construction time." He added, "If technology development can achieve even a 5-10% improvement in construction speed or cost reduction, it will be possible to create a structure that generates operating profits."

There are also calls for government and local governments to present manufacturing revival strategies, including expanding foreign worker quotas and improving residential conditions near shipyards. Professor Kim Young-hoon of Gyeongnam National University’s Department of Naval Architecture and Ocean Systems Engineering advised, "Shipbuilding involves a lot of overtime work, but the implementation of the 52-hour workweek has exacerbated the labor shortage." He suggested, "Temporary or flexible relaxation of the 52-hour workweek for shipbuilding or incentives such as improving residential conditions should be provided."

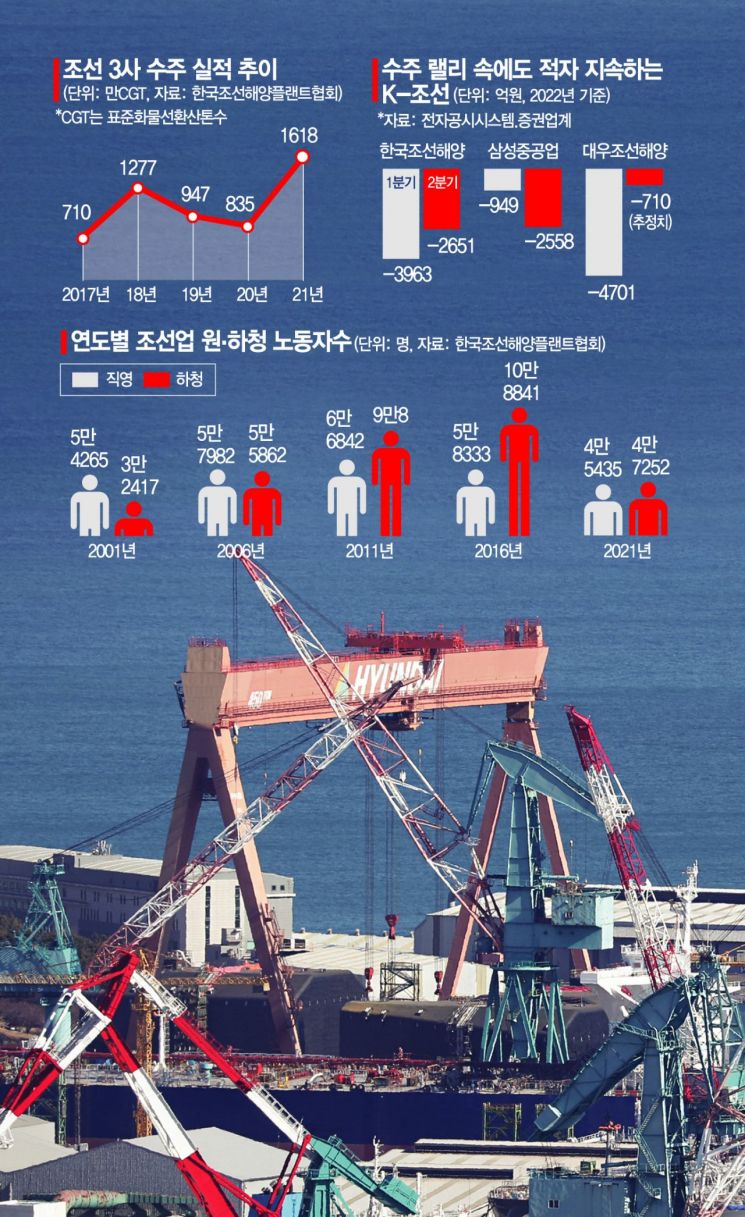

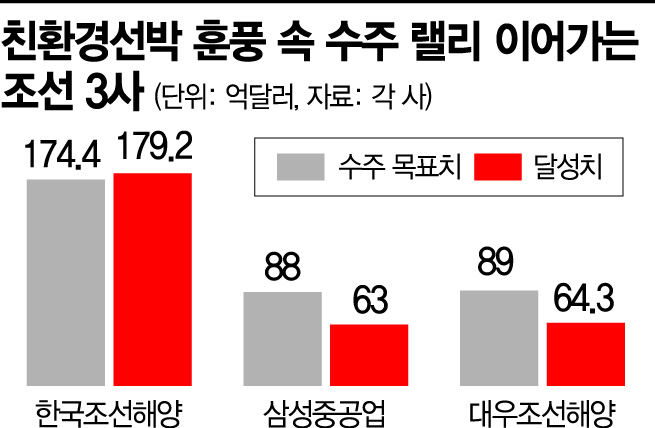

Recently, as Korean shipyards’ order performance has recovered, the order drought is coming to an end. Last year, the domestic shipbuilding industry achieved its highest order volume in eight years since 2013. The Big 3?Korea Shipbuilding & Offshore Engineering, Samsung Heavy Industries, and Daewoo Shipbuilding & Marine Engineering?greatly exceeded their target order volumes, focusing on LNG/LPG carriers, container ships, and oil tankers. Last year, the order achievement rates for Korea Shipbuilding & Offshore Engineering, Samsung Heavy Industries, and Daewoo Shipbuilding & Marine Engineering were 153%, 134%, and 140%, respectively. This year, Korea Shipbuilding & Offshore Engineering has already surpassed its $17.4 billion target, achieving $17.9 billion in orders.

Shipbuilders are also making every effort to attract young talent. They have set plans focusing on nurturing new workers and are making concentrated investments.

Hyundai Heavy Industries and Hyundai Mipo Dockyard are recruiting technical trainees. Their strategy is to create synergy by sharing technology and educational infrastructure through integrated recruitment within the shipbuilding group. In the first half of last year, 230 applicants applied for 100 trainee positions, leading to an increase in the quota to 120. This was due to the effect of fully free education and the provision of training allowances. From the second batch this year, the scale will be increased to 200 trainees, and benefits will be expanded.

Daewoo Shipbuilding & Marine Engineering is focusing on improving the quality of education by opening a VR painting training center. An industry insider said, "As overtime and special work decreased due to the 52-hour workweek, skilled workers moved to other industries," adding, "Government support to flexibly adjust substitute and extended work is urgently needed."

An industry official said, "Each shipbuilder is implementing various policies to secure young workers, but it is true that these efforts are insufficient." He added, "So far, government policies have focused on workforce training infrastructure, but efforts such as establishing joint funds between primary contractors and the government to improve residential conditions around shipyards are necessary."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)