One-Year Results of Big Data Collaboration Platform 'DI360' Announced

"Innovation in Real-Time Inventory Management and Parts Quality Monitoring"

A European-style 21-ton excavator developed by Hyundai Doosan Infracore through big data analysis. (Photo by Hyundai Doosan Infracore)

A European-style 21-ton excavator developed by Hyundai Doosan Infracore through big data analysis. (Photo by Hyundai Doosan Infracore)

[Asia Economy Reporter Moon Chaeseok]

#Approximately half of the 21-ton (t) wheel excavators sold by Hyundai Doosan Infracore in Europe operate in sugar beet fields in the northeastern region of France. Analysis of the automatic measurement system (TMS) data for customers in this area revealed that about 50% of European customers run their equipment in the highest power mode, 'Power+'. In response, Hyundai Doosan Infracore has begun improving the 'Power+' mode performance of the 21t wheel excavator model 'VDK21W,' which is scheduled to launch in the European market in the first half of the year.

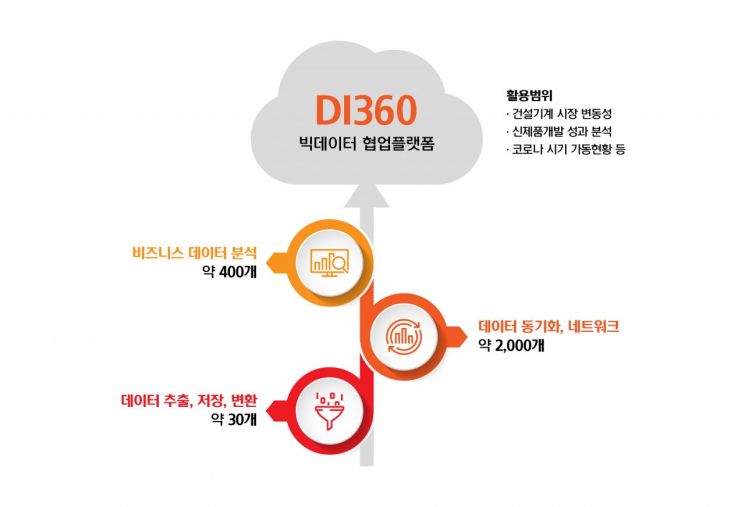

Hyundai Doosan Infracore, a subsidiary of Hyundai Genuine under Hyundai Heavy Industries Group's construction machinery division, announced on the 13th the results of a performance report meeting on the big data collaboration platform 'DI360' and plans to promote a data-driven work culture. DI360 is a big data collaboration platform jointly developed and launched in 2020 by Hyundai Doosan Infracore and the global big data company Palantir Technologies from the United States. It is characterized by integrating data scattered across departments for fast, one-stop analysis and sharing.

Hyundai Doosan Infracore utilized data analyzed through DI360 over the past year to improve productivity, establish inventory management systems, and develop new products. They actively applied TMS data from equipment stored in DI360 to new product development.

Analysis of TMS data showed that domestic customers prioritize fuel efficiency, North American customers focus on engine speed, and European customers emphasize engine power when operating equipment. Domestic customers operate with engine power set to 'Standard' to consider fuel efficiency, while North American customers maximize equipment use by increasing engine power and speed. European customers, unlike North American ones, do not set engine speed as high. However, the VDK21W model, scheduled for release in Europe in the first half of the year, will focus on improving 'Power+' mode performance based on TMS analysis results.

The DI360 platform was also effectively used for inventory and quality management. Previously, data processing for shipped construction equipment took three weeks. With DI360, analysis can be completed in one day. This has accelerated parts lifespan improvement, management, and preventive maintenance, enhancing customer satisfaction. Daily monitoring of material delivery status enabled improved production efficiency through inventory management. They also developed and used a 'Parts Quality Index' that allows real-time monitoring of information such as defect rates from partner companies on a single screen.

A Hyundai Doosan Infracore official said, "Through DI360, we can analyze real-time operating information of construction equipment sold worldwide and market information by country, enabling us to develop new products tailored to market characteristics." He added, "We will continue to do our best to satisfy customers through big data-driven work innovation."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)