SR Technopack Research Institute Achieves Localization of Oxygen Barrier Packaging Materials

Develops New GB-8 Material Resistant to Water and Heat, Offering Lower Costs Compared to Japan

Focuses on Developing High-Barrier Films Including Oxygen-Blocking Infusion Films and Moisture-Blocking Films

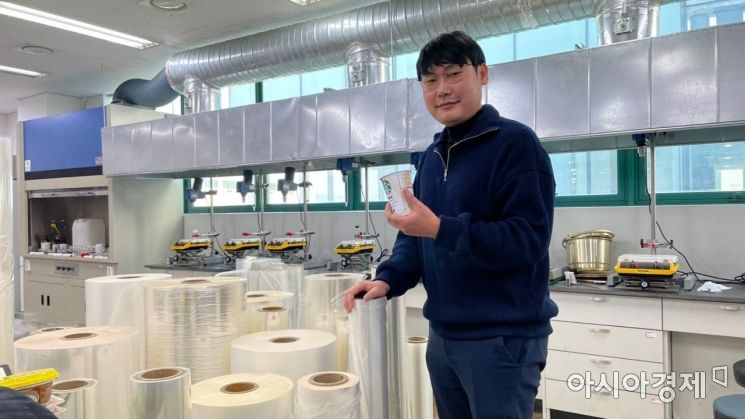

An SR Technopack employee is examining film used for packaging food containers such as instant rice. Photo by SR Technopack

An SR Technopack employee is examining film used for packaging food containers such as instant rice. Photo by SR Technopack

[Asia Economy Reporter Kim Heeyoon] Behind the densely packed vinyl, various experiments using coating films are being actively conducted. On the 24th, the SR Technopack Technology Research Institute in Seongsu-dong, Seongdong-gu, Seoul, was located in an unexpected space inside the office area. Senior Researcher Seong Donghyun explained, “We recently relocated the research institute to Seoul to increase focus on technology development and facilitate communication.”

SR Technopack is the leading packaging container company producing more than half of Korea’s instant rice containers, but it did not make significant profits as it imported all the main materials used for vinyl lids from Japan. After concentrating its capabilities on new material research for sustainability, the company succeeded in developing the oxygen barrier film ‘GB-8,’ achieving material independence from Japan and securing eco-friendly materials.

The core of instant rice vinyl packaging was securing aseptic technology that blocks light and moisture ingress. The ethylene vinyl alcohol (EVOH) film applied here is a technology uniquely held by Japan, making it urgent to find alternative materials. Researcher Seong said, “We reviewed various papers and conducted material tests, focusing on polyvinyl alcohol (PVOH), but it dissolved in water and had weak film adhesion, making it unsuitable as packaging material. After 3,000 tests, we developed a coating technology that does not dissolve in water and is heat-resistant.”

SR Technopack has succeeded in domesticating oxygen barrier film technology, which was previously entirely imported from Japan, and is applying it to instant rice and cup beverage packaging. The photo shows Seong Dong-hyun, senior researcher at SR Technopack, holding and explaining a cup packaging material with the oxygen barrier film GB-8 applied. Photo by Kim Hee-yoon

SR Technopack has succeeded in domesticating oxygen barrier film technology, which was previously entirely imported from Japan, and is applying it to instant rice and cup beverage packaging. The photo shows Seong Dong-hyun, senior researcher at SR Technopack, holding and explaining a cup packaging material with the oxygen barrier film GB-8 applied. Photo by Kim Hee-yoon

Failed Antifouling Coating Technology Became Fertile Ground for New Material Development

The bitter experience of failure also nourished new material development. The company previously ventured into developing antifouling coatings to prevent marine organisms from attaching to ship hull surfaces. After three years of research, it launched a product in 2010, but the market rejected it. The accumulated synthesis and adhesion technologies became the core of the coating technology that can achieve oxygen barrier performance with very small amounts of coating.

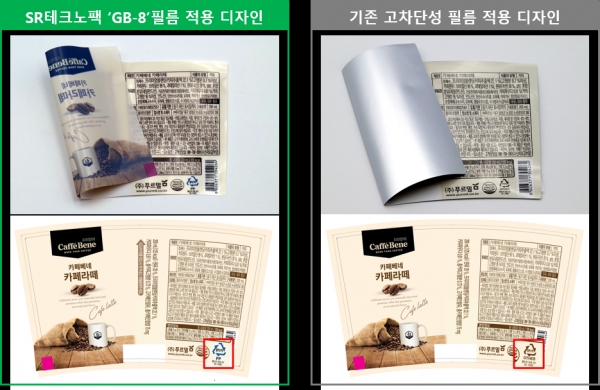

‘GB-8’ is a solution-type coating applied to base films (PP, PET, Ny, PE, etc.) that provides high oxygen barrier effects. GB-8, which also reduces light and moisture permeability, lowered costs by about 25% compared to Japanese EVOH films. Additionally, its coating thickness is thin, and unlike the conventional aluminum foil process, it does not use adhesives, resulting in production cost savings. Even the conservative food industry has visited the research institute to test oxygen and moisture barrier properties and adopted GB-8, which is currently used by more than ten domestic and international food brands.

With the rise of ESG (Environmental, Social, and Governance) management, the industry is focusing on GB-8’s eco-friendly features. Existing packaging materials used heterogeneous materials, making it difficult to recycle plastic (PP) trays or cups bonded with packaging. However, GB-8 is manufactured from the same material as plastic, making recycling easy even when bonded to products. A company official said, “Due to growing environmental interest, demand for aluminum-free food packaging is increasing mainly in overseas markets such as Europe, and we expect the market to expand further.”

The oxygen barrier film technology developed by SR Technopack is made in a solution form, allowing excellent oxygen barrier effects simply by coating it onto base films (PP, PE, Ny, etc.). The photo shows the film developed with GB-8 (left) and a high barrier film product using conventional aluminum foil. Photo by SR Technopack

The oxygen barrier film technology developed by SR Technopack is made in a solution form, allowing excellent oxygen barrier effects simply by coating it onto base films (PP, PE, Ny, etc.). The photo shows the film developed with GB-8 (left) and a high barrier film product using conventional aluminum foil. Photo by SR Technopack

Oxygen Barrier Infusion Film Development Nearing Completion, Moisture Barrier Film Development Initiated

The research institute is focusing its capabilities on developing moisture barrier coating films following oxygen barrier films. Demand for moisture barrier packaging is expanding, especially for products like snacks, ramen, and gim (seaweed), which become soggy or lose quality when moisture penetrates. However, the best moisture barrier film material so far is aluminum. Researcher Seong added, “We have currently developed about 30% (5g) moisture barrier coating technology, but we are continuing experiments aiming to reduce it to 1g.”

SR Technopack is also applying technological advancements to its other core business of manufacturing medical films for infusion packaging. The research institute recently completed the development of oxygen barrier infusion films applying oxygen barrier coating technology and has entered a stage of developing more stable physical properties.

Cho Hongro, CEO of SR Technopack, stated, “Based on the new material GB-8, we are dedicated to developing technologies that can be used not only for food packaging but also for various displays and electronic products that require oxygen barriers. Through the localization of high-barrier film technologies such as moisture barrier films, we will increase the number of globally leading products.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)